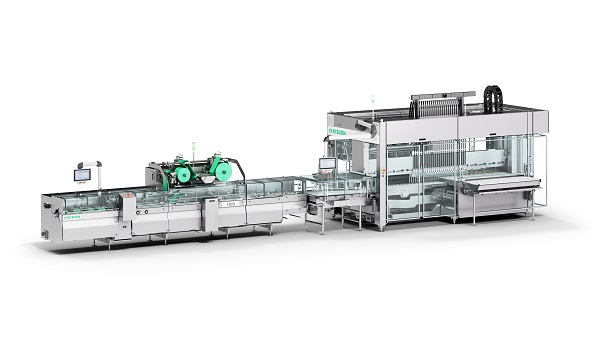

Syntegon showcases its line expertise in horizontal packaging solutions for cookies and bars at interpack (booth A31 in hall 6). The new Syntegon IDH is at the heart of a line which flexibly packages cookies and crackers in trays and flow wraps made of mono-material. Thanks to a new pick-and-place technology with integrated linear motors, it handles products particularly gently. Linear motors also feature in various feeding modules in both lines to prevent product damage during handling and boost flexibility. In addition to gentle handling, the high-performance system for bars that will be on show offers high levels of sustainability and digitalization. The line is equipped with a paper-ON-form forming shoulder and wraps bars in paper before placing them in glueless formed cartons in the TTM1 topload cartoner with an integrated lock-style forming station. Moreover, Syntegon will present a new wireless Human Machine Interface (HMI) that allows operators to access all available information and digital services at any time.

An intelligent and flexible packaging solution for cookies and crackers

At the booth, visitors can experience the full pack style flexibility of the IDH in combination with an HCS form, fill and seal machine live for the first time. The pick-and-place solution for handling and portioning cookies is based on a newly developed technology, as Daniel Bossel, Product Manager at Syntegon, explains: “Thanks to integrated linear motors, each picker can be individually aligned, allowing them to process even random product streams. The number of pickers can be increased to up to 40. At interpack, the IDH achieves a maximum output of up to 800 products per minute – while still maintaining its space-saving design.” Besides that, the station offers manufacturers maximum format flexibility: it groups and loads cookies in four different formats – slug and pile packs, as well as upright or piled cookies in trays – into the downstream infeed. At the same time, the IDH is designed for fast and tool-free format changes – as is the entire line on display.

“Consistent gentle product handling is one of Syntegon's strengths and especially important when processing sensitive products,” Bossel continues. “Therefore, the linear motors are also part of the downstream feeding module FIF. They move particularly slowly and smoothly to protect products from mechanical stress, thus minimizing product loss.” At interpack, the FIF feeding module is integrated into an HCS form, fill and seal machine and feeds the cookies in piles, slugs or trays into the packaging machine. The HCS then wraps them in recyclable film made of mono-material and heat-seals all formats for airtight packs and optimal product protection.

A highlight at Syntegon's interpack booth is a flexible line that packages cookies and crackers in trays and flow wraps made of mono-material. At the heart of the line is the Syntegon IDH, which features a new pick-and-place technology with integrated linear motors for particularly gentle handling.

High-performance bar system for maximum efficiency

The new linear motor technology is also a key feature of the fully automated bar system on display, which shows the packaging process from product distribution to secondary packaging in display cartons. Linear motor technology ensures particularly gentle and flexible product handling in the integrated FIT intelligent infeed module. “Each gripper can be controlled individually and synchronizes optimally with the products – even with random streams,” explains Stephan Schuele, Head of Product Management at Syntegon. “It eliminates the need to accumulate the bars before they enter the packaging machine. This protects the products, reduces the length of the line and facilitates a reliable, continuous infeed even at high speeds.”

In addition, the DCIE discharge station provides a continuous product flow. Bars can be temporarily stored on its waiting conveyor to ensure consistent feeding to the downstream HRM form, fill and seal machine, even if product volumes fluctuate temporarily. The HRM, in turn, is designed for high-performance applications: Thanks to its integrated high-performance splicer, it achieves pinpoint accuracy even during reel changes at speeds of 150 meters per minute. Moreover, operating errors are automatically detected, increasing the availability and efficiency of the HRM – even when processing alternative materials such as paper. At the Syntegon booth, the machine is equipped with a paper-ON-form forming shoulder: It flow-wraps bars in eco-friendly paper without compromising on performance and seals them reliably using cold sealing technology.

Sustainable glue-free carton forming

After packaging, the integrated Sigpack TTM1 topload cartoner takes over the bars for secondary packaging. The intelligent PFI product feeding module is based on linear motor technology and identifies the position of individual flow wraps before gently and precisely loading them into the grouping chain. This eliminates the need for additional mechanical parts such as side guides that could damage the paper flow wraps. Both the omitted format parts and the overall changeover concept of the TTM1 ensure quick and easy format changeovers along the entire line.

“With the new lock-style forming station, Syntegon further adds to its sustainable packaging initiatives. Cartons are formed without using hot-melt glue. This not only protects the environment, but also reduces the system’s energy consumption, minimizes cleaning efforts and sources of malfunction – and, last but not least, saves on consumables,” explains Andreas Schildknecht, Product Manager at Syntegon. The lock-style module is also available as a retrofit kit for many Syntegon cartoners.

Another innovation launched at interpack is the new wireless HMI 4.0 – a new feature that boosts efficiency, especially in large, fully automated systems. It allows operators to control and monitor the entire line via a single interface. In case of malfunctions and maintenance work, they can immediately access all the important information and instructions to restart the line as quickly as possible. Tool-free format changes on all line components further reduce downtimes. This not only ensures a consistently high performance, but also reduces the workload to a minimum. Its easy cleanability additionally supports operators during the daily operation of the line. As a bonus, the line is particularly low-maintenance and ideally suited to the requirements of a three-shift operation.

Interface with digital services

Synexio also contributes to the optimal monitoring of the equipment: The new cloud-based software solution collects, evaluates and visualizes machine and production data. Syntegon will offer Synexio in three consecutive packages. The basic package “Monitor” visualizes various KPIs and thereby improves production transparency. “Now that our customers are successfully implementing the basic package, we are ready to upgrade to the next level,” says Elisa Hein, Product Manager Expert Services at Syntegon. At interpack, Syntegon will present the second Synexio package “Uptime”. “With this, we are delving deeper on the details: Besides machine availability, we can now also identify specific potential for improvement, for example by visualizing the most frequent reasons for stops,” explains Hein.

Synexio is also part of the Service Agreements that Syntegon offers for the machines of the cookie and bar packaging lines. They provide the foundation for effective equipment and maintenance management at fixed prices. Seven dedicated levels help customers from the pharmaceutical and food industries to reduce production risks, gain predictability on service costs and simplify complex processes – enabling them to focus on their core business. With each level, the scope of services covered increases – from basic service, including inspection and remote service, to guaranteed production performance of the machines. From Level 4, customers can enjoy peace of mind about the total cost of ownership for the lifetime of their equipment. Besides preventive maintenance and operator training, services at this level include all spare parts at a fixed cost.