The VDW (German Machine Tool Builders’ Association), Frankfurt am Main, has acquired a minority stake in Munich-based Spanflug Technologies GmbH. The contract was signed last November. The start-up has been operating since 2018 and was spun off from the Institute for Machine Tools and Industrial Management (iwb) at the Technical University of Munich (TUM). Its declared aim is to automate the quotation and parts procurement processes for the manufacturing industry. It provides two products for this: a platform on which customers can interact with suppliers and process their orders, and software which suppliers can use to generate their offers automatically, quickly and transparently.

“The VDW enjoys excellent links throughout our industry, and we are delighted it has come on board. It’s the ideal partner for us,” said company founder Dr. Markus Westermeier. “Both sides were interested in establishing a close, long-term cooperation beyond the purely consultative. The idea of a financial involvement on the part of the VDW was floated and then very quickly implemented,” he continued. “We enlisted the support of some of our members to evaluate the Spanflug solution and found that it leads the international competition when it comes to the analysis and cost calculation of CNC parts,” added Dr. Wilfried Schäfer, Executive Director of the VDW. “The stake offers great potential, not only for our member companies and their customers, but also for the mechanical and plant engineering sector as a whole in Germany. The aim is to use the Spanflug technology and its resulting efficiency gains to secure the long-term competitiveness of the German manufacturing industry.” He went on: “The participation represents a new field of business for the VDW and thus opens a fresh chapter for us. In times of upheaval it is especially important to be expanding our portfolio as part of our efforts to remain attractive to new members.”

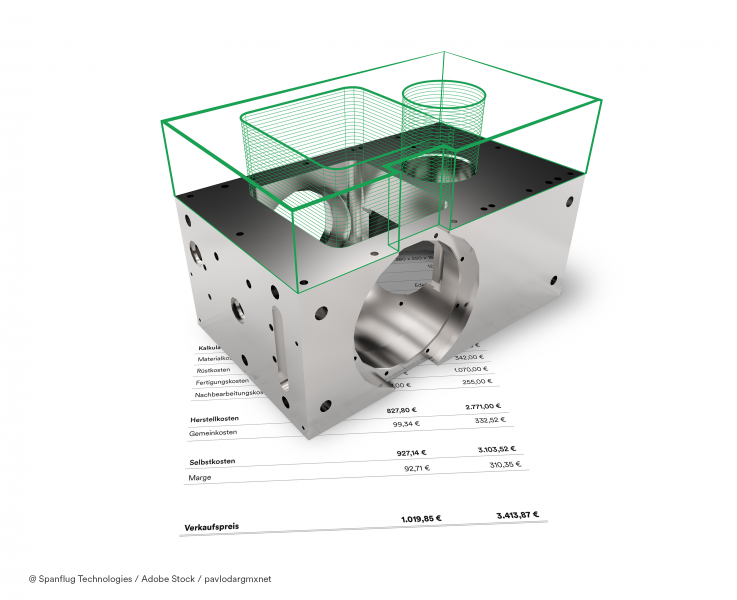

The Spanflug Technologies manufacturing platform specialises in CNC turned and milled parts. It offers customers a fully automated procurement process, including everything from price calculation through to an online shop where orders can be placed. Customers are given the price and delivery time during the enquiry itself. “Our software automatically calculates the price based on CAD models and technical drawings,” explained Dr Adrian Lewis, co-founder of Spanflug. “A new price can be recalculated immediately if any changes are made to the design. We’re currently able to calculate prices automatically for over 90 per cent of the components on the market. This is based on a pricing algorithm which we developed ourselves and which we are constantly refining in order to be able to process even more components automatically,” he explained. More than 1,000 customers are now ordering components on the platform and prices have been calculated for more than 100,000 production parts.

A large network of more than 70 high-performance manufacturing companies from Germany and Austria is already connected to the platform. “We attach great importance to this, as it ensures high quality and fast deliveries,” affirmed Lewis. The benefits for customers are that it can shorten the entire ordering process from days to a few minutes, it saves time in the search for suppliers, and minimises the work involved in ensuring suitable supplier quality and the outlay for communication. This reduces the ancillary costs of procurement. For their part, the manufacturing companies can eliminate unused capacity and make savings in sales and marketing.

Spanflug’s second pillar is also based on the platform and is a software service in the form of automatic price calculation for manufacturing companies. They can use this software to automate their costing process and generate customised quotations at the click of a mouse.

Spanflug’s founders see great potential in automated costing processes, both for the customers and for the manufacturing companies themselves. The participation of the VDW will allow them to ramp up the development of their platform technology and significantly expand it by getting the machine tool manufacturers involved. “The VDW brings extensive industry knowledge to the table and is thus the ideal partner for us here. Ever since talks began we have been seeing increasing benefit from our access to the VDW’s network and the close proximity to the machine tool industry,” concluded Westermeier.