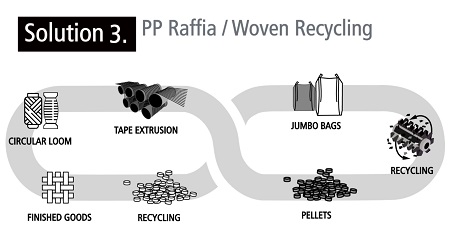

Post-industrial recycling of PP raffia, woven sacks, tapes, non-woven/woven products could be challenging at times for some producers due to several reasons. One is that it is difficult to process in one single step due to size and strength of the waste material waste, for example for FIBC and jumbo bags. When recycling has to be done in several steps, it is not cost-effective for the producers in terms of labour, electricity, as well as several machines occupying a large factory space.

Another issue is the retention of material property (strength and elasticity) after recycling in which the material degrades excessively and therefore, the reusability of the recycled pellets back into the production lines is relatively low. Last concern is the difficulty to process heavily printed woven bags (for example AD*STAR bags) as the degassing and screw design of the recycling machine is not ideal for this type of material with extra amount of ink.

Raffia waste is more difficult to recycle compared to film waste.

Simple solution for raffia/woven recycling

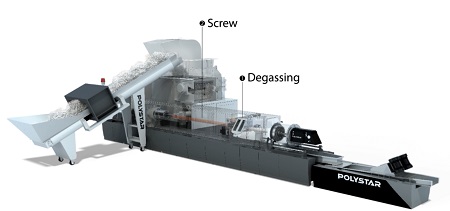

Polystar’s Repro-One recycling machine provides solutions to the above problems due to its features that include one-step process with shredder + extruder + pelletiser all integrated into one simple, easy to operate recycling machine.

Repro-One integrates the shredder with the extruder,

allowing a more automated and consistent feeding of the material.

The recycling system features low processing temperature in the single shaft shredder. This gentle and short, one-step process ensures minimal material degradation, to allow producers to re-use a higher percentage of the recycled pellets back into the production lines and still meet industrial standards (for example, strength and elasticity of jumbo bags for US exports).

Powerful single shaft shredder cuts the raffia waste

within a short time at a much lower processing temperature.

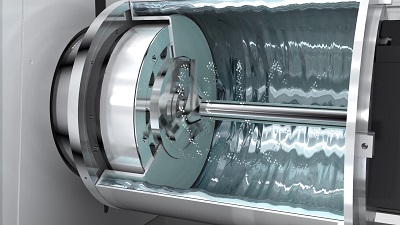

The Polystar machine has a specialised degassing and screw design for processing heavily printed bags. The optimal screw design can eliminate the problem of material coming out from the degassing (venting) area almost completely, so the machine can operate at full speed with stable production. Efficient degassing is another key factor to ensure the pellets are solid (instead of fluffy and hollow in the middle).

High efficiency degassing and specialized screw design

can process printed woven bags into quality pellets.

The machine is integrated with simple and easy-to-use automatic pelletising system for PP. The die face cutting design of the Repro-One is designed specifically to work with PP material. The automatic pelletising speed adjustment prevents pellets sticking due to higher melting index of PP material. This enables the production of more uniform-sized pellets without labour intervention.

Heavily printed woven bags are usually more difficult

to recycle and reuse in post-industrial applications.

Another important feature is the automatic blade pressure adjustment that allows the pressure between the pelletising blades and the die head to remain constant. As a result there is less machine down time, easier and faster to change blades.

Pelletising system of Repro-One prevents

PP pellets from sticking to one another.

Advantage of in-house recycling

Another important benefit of the Polystar Repro-One recycling machine is that the machine is ideal for in-house recycling. In general, 8% of production waste is generated during the process (from tape line production, looming and printing). The price of raw material is almost doubled compared to the cost of having it recycled in-house. It would make sense for medium and large-sized raffia/woven producers, who generate more than 30~40 tonnes of scraps per month or more, to recycle the production waste internally to reduce production cost.

Plastic packaging in circular economy – raffia and woven sector

In the case of a woven sack producer who used to recycle using off-line shredders and agglomerators before feeding the material into the extruder, the installation of Repro-One 100 in the facility has enabled the producer to reduce operation cost by as much as 30%.

Raffia producer in Kenya has replaced its old

recycling machines with a Repro-One.

Trusted name: 257 installed worldwide

Many raffia and woven producers have already seen the benefits of doing in-house recycling using the Repro-One, including producers in Argentina, India, Indonesia, Mexico, Philippines, Saudi Arabia, Thailand, Turkey and many others.

Among the 62 installations in India, one of the Indian producers has already installed four sets of Repro-One in four different factory locations since the first installation way back in 2015. “It is cost saving and our operators find it very easy to run and maintain the machines,” said Mr. Kumar, director of Kolkata-based jumbo bag producer. “The shredder integration is definitely the best choice for raffia and woven application,” he added, explaining the reason why they decided to add the second, third and fourth machine in 2017, 2018 and 2020. “We produce all types of products with different sizes and shapes including cement bags, sugar bags, fertiliser bags, mesh bags (for packing onion, ginger, garlic, potato), and the machine can handle it all with ease.” Mr. Kumar also said that they also recommended the machine to their friends in the industry who produce mosquito and construction nets, and they are very happy using the machine as well.

The high quality pellets ensure easy reuse back again in the production process for raffia, non-woven, and Ad*Star block bottom heavily printed bags. The reusability of the PP recycled pellets is particularly high with the Repro-One recycling machines, raffia producers can use between 20% to 100% recycled pellets back into the production line depending on the final product requirement.

For more information, visit the Polystar Showroom at: http://www.industrysourcing.com/client/supplier/details.html?id=101523