SMOOTH, soft and natural, silk has been for years used for many applications, foremost of which is textiles. It has also been increasingly used in furniture, parachutes, medicines and as a biomedical material. But food?

A new food tech innovation uses silk fibroins produced using a water-based process to create a protective coating for food to prolong freshness and prevent early spoilage. This silk-based coating can be applied on whole or cut produce, meat, poultry and seafood, and can be used with a wide range of other food applications by changing the properties and quality of the silk to suit different food biostructures. It has been proven to reduce the yellowing and wilting of kale, pitting and dehydration in cherries, and microbial growth in cut vegetables. It also helps maintain the colour and texture of vegetables, the stem greenness of fruits like cherries and the colour of beef. It can even enhance sensory experience with both hard and soft candies.

Beyond extending food shelf life, the silk-based coating does not compromise the taste, odour and texture of the food. Silk in itself is odourless and tasteless and therefore has no impact on these food attributes. As the coating is very thin and transparent, it does not affect the appearance of the food except for enhancing the appeal from looking fresh.

Further, this new technology, which takes an upstream innovation approach, tries to provide a root-cause solution to the growing problem of both food and plastic waste. By keeping food for much longer and prolonging its usability, the silk-based coating hopes to address the problems of food waste at an earlier stage instead of the usual final phases as recycling emphasises to prevent waste creation. With the edible coating doubling as packaging, the need for a separate, usually plastic, packaging is eliminated. Besides further streamlining the production process and lowering costs by taking out (plastic) packaging, this food tech innovation provides a sustainable – and edible –packaging alternative for a wide variety of food items.

“The pandemic has shown us that indeed there is an urgent need to make the food infrastructure much more resilient for us to be able to face problems like this global health crisis and the effects it created. The food supply chain is in crisis, and we need new solutions to efficiently and sustainably make food,” said Benedetto Marelli, co-founder of the technology and assistant professor of civil and environmental engineering at MIT and principal investigator at Disruptive & Sustainable Technology for Agricultural Precision (DiSTAP), an interdisciplinary research group of the Singapore-MIT Alliance for Research and Technology (SMART), MIT's research enterprise in Singapore.

“Food waste is a big crisis – one of the biggest problems in my opinion. We're wasting food that can feed 1.6 billion people. We're wasting resources to make food that is not eaten. We're producing greenhouse gases for food that is not eaten. Food waste is the third largest greenhouse gas source,” Marelli added.

From Bombyx Mori cocoon fibres, silk fibroin used for Mori coating is extracted and undergoes dialysis in deionised water. Foods like strawberries are dip-coated in the silk fibroin suspension to extend their freshness. (Photo : SMART DiSTAP)

Innovative yet sustainable food tech

Discovered almost accidentally whilst Marelli was preparing for a lab cooking competition that requires the use of silk, the technology taps into sericulture to develop food innovation that provides a natural barrier that is also edible. Extracted using a water-based process, the silk fibroin helps keep the oxygen out to prevent oxidation but keeps the water in for improved water retention. It also protects the food against microbial growth. All these help keep food fresher for much longer and therefore, mitigate food waste.

“The process of reverse engineering the silk cocoon was discovered in the '60s and we have been able to capitalise on the technology in recent years by engineering the self-assembly or directing the assembly process of molecules in the silk solution. Our goal is to transform the fibre produced into advanced materials that can target food and agriculture,” Marelli shared.

The silk-based coating is ideally applied at harvest stage or even preharvest to prevent dehydration and manage the ripening process. For leafy vegetables such as kale, for instance, applying the coating at the point of harvest guarantees a longer shelf life. “But there are instances where shelf life needs to be prolonged at the downstream stage just to create more value. We can also look into applying the coating at that latter stage,” he added.

The silk fibroin can be integrated into pre-existing harvest and wash steps and into existing equipment. We can retrofit all equipment currently used to apply food coatings using the silk solution.

“With this new food coating technology, we do not only prolong the shelf life and reduce waste, although of course these are very important benefits. We add value across the entire supply chain. The same material can be used for packaging – edible packaging – so it addresses the packaging and plastic issues. Because food can stay fresh longer, they can be shipped much farther, which means we open new markets, which in turn, expands the access to fresh food for more people,” Marelli said.

The new silk-based coating even helps reduce the need for refrigeration. “With the strawberries, for example, the extension of the shelf life didn't involve using the fridge. We also have two coating types – one that can be washed away and another that can't be rinsed off. This latter type can survive cleaning at home, further helping with food hygiene and storage,” Marelli said.

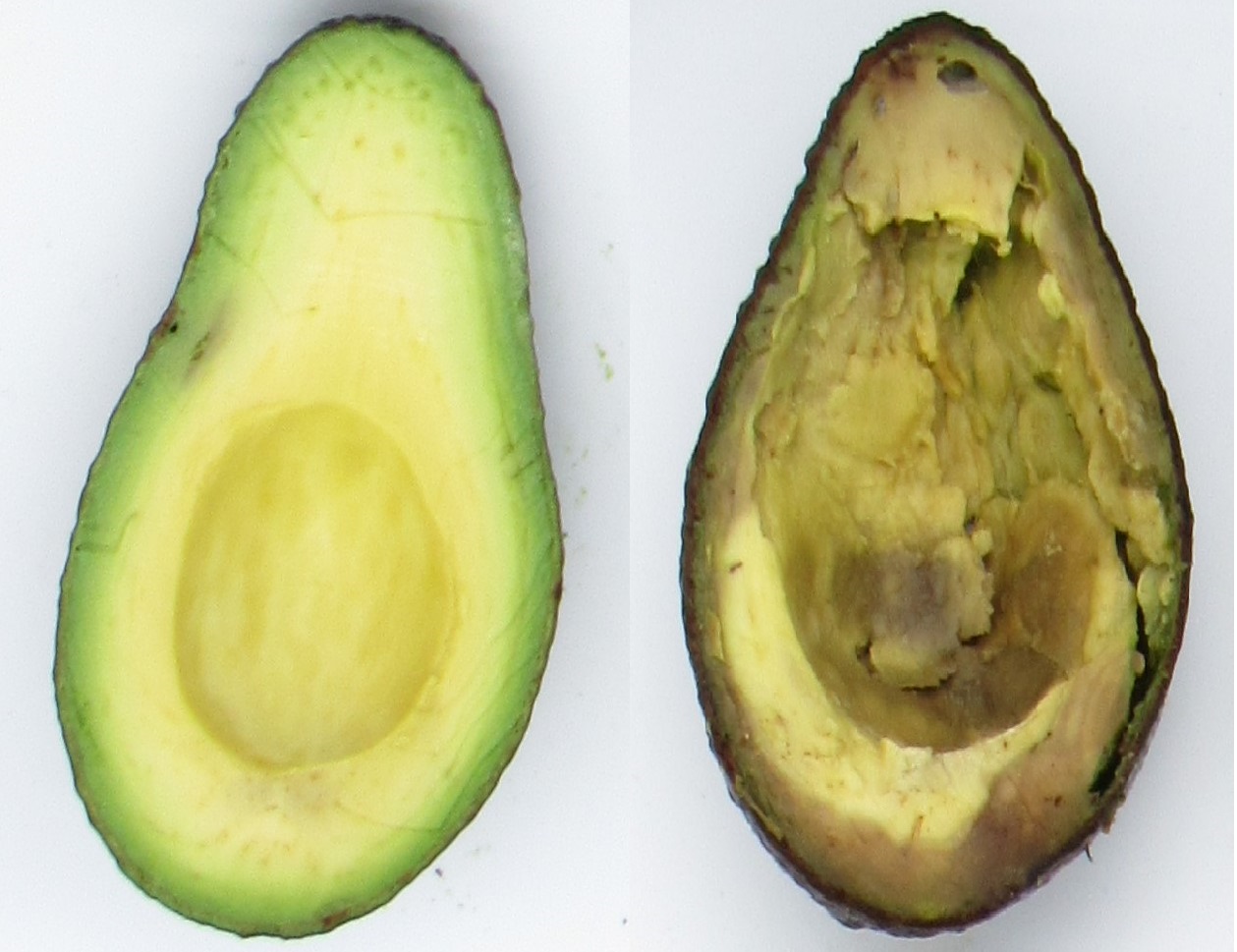

Striking difference: on the left, avocado coated with Mori retains its freshness longer compared to the one on the right which has undergone its natural state of deterioration. (Photo: SMART DiSTAP)

Mori, formerly Cambridge Crops and renamed Mori after the Bombyx mori silkworms used for its silk fibroins, has raised US$17 million thus far to scale up production. Pilot studies have been done and the company is targeting products in the next 18 to 10 months.

The silk-based coating technology has secured Self-Designated GRAS (Generally Recognised as Safe) status from the US Food and Drug Administration (FDA) for use in a wide range of food applications and is expected to obtain additional certifications from the FDA and US Department of Agriculture (USDA).

SMART, through its DiSTAP interdisciplinary research group covering agriculture amongst others, is working with Marelli on the research of these biomaterials such as silk. SMART's Innovation Centre, in particular, is helping in this stage of the project.

According to Marelli, caterpillar cocoons can be regenerated in a solution that can be maintained as a solution or freeze-dried in a powder form for re-exposing later to make the solution. The coating can be applied by spraying the solution on to the food such as a fruit or deep coating the food into the solution like in a fondue.

“The coating can't be used on all food items at present but there's still a lot of room for improvement because the molecular structure can be changed depending on the food,” he added.

The edible coating is ideally applied at harvest stage or even preharvest to prevent dehydration and manage the ripening process. It can help slow the yellowing of leafy vegetables, which is a boon to the supply chain. (Photo: SMART DiSTAP)

Marelli's research group, which works in the areas of structural biopolymers and nanomanufacturing, is now also looking at other polymers that can be mixed with silk to further enhance the barrier properties.

“We are experimenting with polyvinyl alcohol, for one. This is a synthetic polymer that is also soluble in water, odourless and not toxic and is widely used in pharmaceutical and food applications. We are working with it in combination with silk, testing different weight ratios for the two to try to change the microstructure of the coating to further control the barrier properties of the output material,” shared Marelli.

Marelli said they are looking into other applications for the silk fibroins as well.

“Knowing how to assemble and how to template the assembly of the silk, the fibre can be engineered into other different material formats, make new fibres or make particles of different dimensions from the micro to the nanosphere. We can make gels that can be transferred into hollow structures, even start to use advanced fabrication techniques for 3d printing, photonic crystals and other applications,” he said. He and his team hope to expand applications in biomedical engineering, regenerative medicine and drug delivery.

But why silk?

Because silk itself is natural, using silk allows for the coating to be edible, a huge factor in realising edible packaging.

“The entire process of creating the silk-based coating happens at room temperature, with neutral pH, and the whole regeneration process happens in water,” Marelli said. He added caterpillars are consumed in many parts of the world and there are food ingredients that are basically powderised or floured silk, so it will not be uncommon to coat a food in silk fibroins and to eat that coating as well.

“What's even more interesting is the fact that silk production is huge. So, there's supply that is easily tapped,” added Marelli.

Raw silk (Photo: SMART DiSTAP)

Mori's silk fibroin coating uses silk that is low grade or that which is not good for textile applications. “When one thinks about silk, one immediately thinks very expensive material. But there's so much silk that is wasted because it's not good enough for textile companies. Those can be repurposed or used for other equally important things,” he added.

What Marelli's team needs to figure out is the logistics aspect of moving silk from parts of the world that produce silk to their production facilities.

The team is likewise seeking to obtain Halal and Kosher certification. “Some might not feel comfortable eating animal protein. Others might be concerned that the silkworm suffers in the process. We can have cocoons where the caterpillar can exit and become a moth so the caterpillar can go through with its life cycle. We don't need a single thread of silk like textile companies. We're working actively with all these realities to develop the best way to source our silk. One other way is to produce silk using synthetic biology, and there are already companies doing this. They don't have the same yield that we can have though. But we can look into the synthetic biology side more to achieve the volumes required for agriculture and food. That's one area for future development for sure,” Marelli shared.