Ever smaller, ever lighter – many developments across vastly different industries are driven by the trend towards miniaturisation or lightweight construction. For mechanical engineering and suppliers, this results in entirely new challenges for metal machining. Walter AG, based in Tübingen, Germany, is providing its customers with a solution for this range of applications in the form of HIPIMS PVD cutting tool materials, introduced in 2017. Their excellent process stability and above-average tool life have already impressed many customers.

Even though it is most apparent in the field of communication and entertainment electronics, the trend towards miniaturisation is shaping many areas of industry: From the medical industry, to the automotive industry, right through to aircraft construction. For producers, this means that they must adapt their processes to increasing demands for dimensional stability and surface quality or even switch to new materials.

Particularly hard, but also particularly tough, materials (such as Inconel 718DA with 42 HRC in the aerospace industry or Ti-6Al-4V in the medical and food industry) have complex requirements for the indexable inserts during ISO turning. This is because tough materials have a high tendency for adhesion, especially when they have a high nickel content (Ni). This results in the chips sticking to the cutting edge forming a build-up on the cutting edge. The dimensional stability and the surface quality suffer. The fact that cutting edges become worn relatively quickly had to be accepted until now, especially in the case of high-strength materials.

During ISO turning operations with high to medium depths of cut, the CVD-coated indexable inserts which have previously dominated the market offer good to outstanding possibilities. However, they reach their limits in machining applications such as finishing and fine finishing, particularly where precision and tool life are concerned. This is where Walter's machining specialists identified major potential for optimisation.

Gerd Kußmaul, Senior Turning Product Manager at Walter, describes the concept behind the new HIPIMS PVD-coated indexable inserts as follows: "Even if the fine finishing and finishing of ISO M, ISO S, ISO P and ISO N materials with the highest requirements for surface quality are still special or niche applications at the moment, we see great potential here due to dynamic growth in the market right now. Fine finishing involves turning operations which are designed to achieve a consistently good surface quality. This is in the range from Rz 1.6 μm to Rz 6.3 μm – throughout the entire tool life of the indexable insert. This is why for some time Walter has been looking for geometries and cutting tool materials that achieve this with process reliability. The new PVD HIPIMS coatings demonstrate ideal properties for achieving this with their extremely smooth surface and great layer adhesion on sharp cutting edges."

Innovative coating technology to ensure best performance

Walter is one of very few indexable insert manufacturers to perform the new PVD HIPIMS process in-house and continuously expand the application possibilities with a dedicated PVD development team. HIPIMS stands for "High Power Impulse Magnetron Sputtering". In contrast to conventional DC sputtering processes, the HIPIMS process involves subjecting the targets to short pulses of a few kilowatts of power. This produces a plasma density of 1013 ions per cubic centimetre, which have a high content of target metal ions. The bonding of the layers to the substrate is also excellent.

Indexable inserts with extremely sharp geometries, such as the FN2 or the MN2 "Aluminium geometry", benefit from this coating process in particular because extremely stable cutting edges are produced. Even under high loads, the layers do not chip off and the cutting edges do not break away. In addition, the high level of edge stability ensures that the cutting edge is not only subjected to less wear, but that this wear also occurs evenly. The even wearing ensures dimensional stability and defined surface quality, even right up to the end of the tool life. Another advantage of the HIPIMS process is that the coatings are extremely smooth making them ideal for machining sticky aluminium alloys, for example; materials which would otherwise stick to the cutting edge during machining now reliably glide over it. Typical forms of wear such as built-up edges or significant flank face wear caused by chemical and physical reactions with the adhering material rarely occur. Walter's new HIPIMS PVD grades WNN10 and WSM01 also have a long tool life.

Long tool life, increased machining volumes

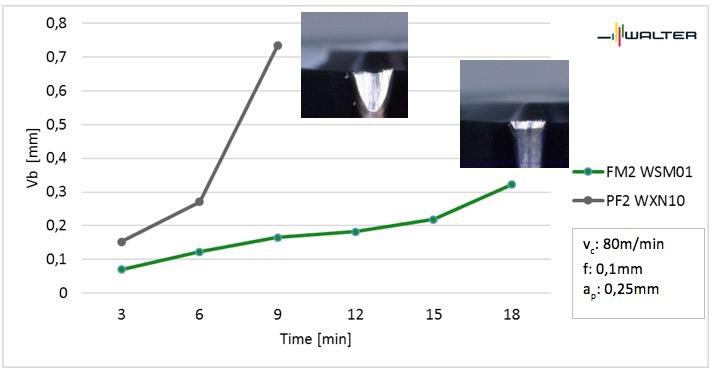

Since the launch in 2017, sales for the HIPIMS PVD indexable inserts has grown consistently. Walter is pleased with the positive response from many customers who have already made the change from the previous WXN10 or WK1 cutting tool materials to the PVD-coated WNN10 or WSM01 indexable inserts. Walter Product Manager Gerd Kußmaul reports: "There must be good reasons to change the cutting tool material in established processes. Among other factors, the outstanding results achieved by the new HIPIMS grades with regard to tool life and surface quality speak in their favour. This is clear to see from the comparative tests. For instance, when performing finishing operations on tool steel X40CRMoV5-1 (DIN1.2344) with 54 HRC, it was possible to increase the tool life by 275%. And the surface value of Ra 0.8 μm was achieved throughout the entire tool life with process reliability. Another application was finishing Inconel 718DA at a cutting speed of 80 m/min, with the new grade WSM01 and achieving a cutting time of 18 minutes. In comparison to this, the previous grade WXN10 was only able to achieve nine minutes. In addition, a consistently good surface quality between Rz 2 μm and Rz 4 μm was achieved throughout the entire tool life."

Process reliability and cost reduction

Walter's new HIPIMS PVD indexable inserts have potential to be effectively used anywhere that maximum precision, surface quality and process reliability are required. At the same time, these inserts have a positive effect on costs because the HIPIMS PVD coating, in conjunction with a carbide substrate, results in a cutting tool material that offers a long tool life with consistently high machining quality right to the very end. This is especially true for difficult machining steps such as fine finishing and for very sticky materials such as aluminium alloys with a high silicon content. In fact, the tool life and surface quality differences compared to previous indexable inserts are so significant that they result in a noticeable cost reduction in production.

INFOBOX:

Optimal surface quality when finishing and roughing

Walter developed the new WNN10 grade for finishing and roughing of ISO N materials such as aluminium-, copper- and magnesium-based alloys. The indexable inserts are available in two geometries. The FN2 geometry with 18° rake angle is ideal for finishing operations and for long, thin shafts that tend to vibrate. The MN2 geometry with 25° rake angle can be used universally for medium machining of non-ferrous metals.

The new grade WSM01 is available in the FM2, MM4 and MN2 positive geometries and in the MS3, NMS and NRS negative geometries. Its main area of application is finishing and medium machining of nickel- and cobalt-based high-temperature alloys (ISO S) but it is also used with stainless materials (ISO M) such as austenitic stainless steel 1.4301, 1.4404 or duplex steel 1.4462. It is used, for example, for machining engine components in the aerospace industry or for producing surgical instruments in the medical industry. Its applications also include machining stainless steels or hard turning tool steel such as X40CrMoV5-1 with 54 HRC. To summarise, it can be said that the new HIPIMS PVD grade WSM01 is the ideal solution for fine finishing of hard materials.

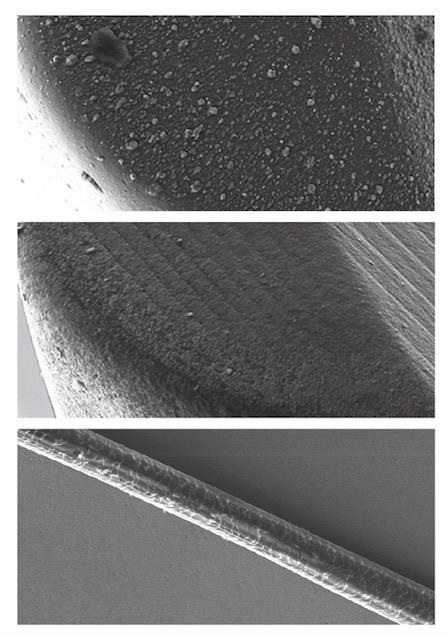

Surface comparison

The surfaces produced using the HIPIMS PVD process are extremely smooth. This reduces build-up on the cutting edge and the generation of heat thanks due to reduced friction.

Top image: Standard PVD process: Increased droplet formation

Middle image: HIPIMS PVD process (WNN10): Extremely smooth surface

Bottom image: HIPIMS surface and structure of a hair as a direct comparison

Finishing of Inconel 718 DA – 40 HRC with Vc: 80 m/min

With identical cutting data, the new HIPIMS PVD-coated DCGT11T304-FM2 WSM01 indexable insert increased the tool life from nine minutes to 18 minutes compared to the DCGT11T304-PF2 WXN10 indexable insert and consistently achieved a surface quality between Rz 2 and Rz 4 μm throughout the entire tool life.