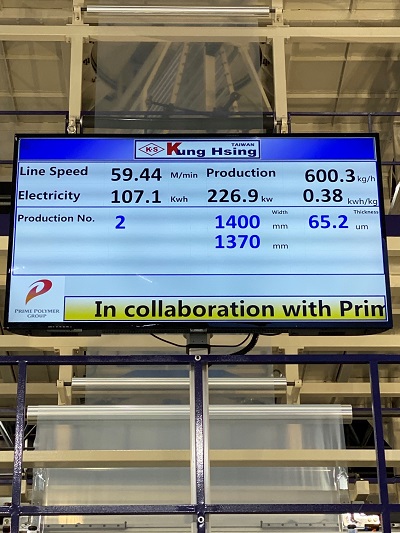

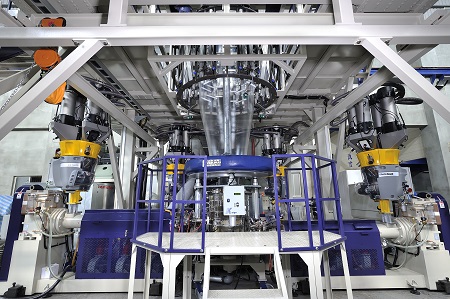

Kung Hsing, a pioneer in blown film extrusion lines in Taiwan, introduced its latest die design in the 5-layer co-extrusion blown film line model, and with this die design, the machine achieved an exceptional performance putting it above its competitors.

The new 5-layer die design reduced melt resident time, quick change-over, consistent melt distribution, and high output rate. This design is capable of a throughput of 600 kg/h with Ø300 mm die, and enables the rate of return that is 2 times the diameter of the die. Such innovation seals Kung Hsing’s special position in the blown film sector where the market is always on the lookout for solutions that can improve profitability at lower production costs.

This article provides an overview on how the 5-layer co-extrusion blown film line from Kung Hsing Plastics Machinery Co., LTD. can meet these essential requirements:

Capability of consolidating oxygen and moisture barriers

Processing of recyclable All-PE multilayer structure film

Increased productivity and efficiency of the production lines

Kung Hsing focuses on meeting stringent regulations for food and beverage packaging

At present, the world market is seeing increased exchange of fresh meat and seafood in various regions, thanks to export agreements covering the trade of meat products. This scenario is leading to more countries having high demand for safe and hygienic packaging.

Kung Hsing has been monitoring the trends in food and beverage packaging. In response to market developments, Kung Hsing has developed and introduced the 5 -9 layer co-extrusion blown film line that is capable of consolidating oxygen and moisture barriers through a high safety standard to prolong the freshness of food. This makes the packaging appropriate for storing frozen meat and seafood down to -50°C, dairy products and cookie packaging, etc.

Kung Hsing's film production lines can process recyclable All-PE multilayer structure to achieve a circular economy

In addition to meeting the high demand for food and beverage packaging, the 5-layer co-extrusion blown film line can also process recyclable All-PE multilayer structure film, gaining more relevance in an industry that is fast moving towards a circular economy.

This characteristic is built based on the increasing awareness in the application of environmentally-friendly materials. In this regard, Kung Hsing has been keeping the balance between improving recyclable All-PE multilayer structure film and reducing the price of this innovative technology.

Kung Hsing raises productivity and efficiency through automation

“For years, we have been dedicated to improving extrusion equipment, thus as compared to our other extruders, the result was a 30% increase in production. We managed to increase production capacity while keeping energy consumption at the same level. In addition to energy efficiency, performance in terms of speed is the best characteristic of our multilayer film co-extrusion machines”, according to the Vice President of Kung Hsing.

Within the perspective of maximizing production capacity as aligned to the demanding packaging sector, Kung Hsing offers automation system multilayer machines request less personnel, which makes the machine achieve high precision, enhanced efficiency, and increased production throughput rate at the same time.

A blown film line at the forefront of emerging needs

As a leading producer of blown film extrusion lines, Kung Hsing Plastics Machinery Co., Ltd, located in Chia-Yi Hsien, Taiwan, offers complete 3-layer to 7-layer systems for processing HDPE, MDPE, LDPE, LLDPE, mPE, EVA, PP, PA, EVOH, recycled material and biodegradable compostable material.

Kung Hsing blown film line is ideal for the production of barrier film, laminated film, VCI film, food packaging film, industrial packaging film, FFS, heat shrink film, agricultural film and biodegradable film.

The company has been increasing its market share in Southeast Asia in recent years where it aims to expand by meeting the requirements of its target customers in the region.

For more information on Kung Hsing and its products, contact:

Kung Hsing Plastics Machinery Co., LTD.

Tel: +886-5 237 4466

Fax: +886-5 237 6971

E-mail: ks.sales@kunghsing.com.tw

Website: www.kunghsing.com.tw