By: Kathryn Gerardino-Elagio

Today’s manufacturers face enormous challenges even before COVID-19 arrived. They are under increased pressure to accelerate their time to market in order to remain competitive on the global scale. In June 2020, Creaform conducted a virtual press conference announcing the release of the latest version of MetraSCAN 3D® lineup, the company’s advanced optical CMM scanner designed specifically to perform metrology-grade 3D measurements and inspections, right on the production floor.

Patrice Parent, Asia Pacific Territory Manager

To learn more, International Metalworking News for Asia asked Patrice Parent, Creaform’s Asia Pacific Territory Manager more details about MetraSCAN BLACK and how it can help customers in South East Asia during this turbulent time, including the company’s digital strategies and how it is responding from a marketing perspective.

3D measurement technologies

The scale of the impact on manufacturing eclipses anything most industrial companies have had to deal with. And right now, companies must ensure their manufacturing operations are resilient whilst protecting their business.

With product quality issues impacting scrap rate, production ramp-up, production rate, and downtime, ultimately affecting production costs and overall profitability, manufacturers need to rely on innovative 3D measurement technologies, like the MetraSCAN 3D, in order to refine their product development and quality control processes.

Patrice said, “The speed, accuracy, versatility and overall performance of MetraSCAN BLACK can help manufacturing companies in South East Asia to deploy local or internal processes. For example, setting up metrology capability instead of using third party suppliers for their inspection needs.”

Unmatched performance

The MetraSCAN BLACK dimensional metrology system has been developed to measure complex parts and assemblies from an array of industries and manufacturing processes, such as automobile, aeronautics, power generation, heavy industry, metal casting, metal forging, sheet metal, plastic injection, composites, etc.

“Our value proposition is adapted for all customer type, whether they want to deliver parts as fast as possible or want high-quality parts that will be approved, or for those who want to solve production issues,” he explained.

Patrice mentioned, “The MetraSCAN BLACK performs 3D inspections on a variety of complex parts, sizes, materials, and finishes —both in the lab and on the shop floor —quickly and efficiently and delivers approved quality parts based on the fastest and most accurate shop floor portable CMM.”

Highlights of MetraSCAN BLACK

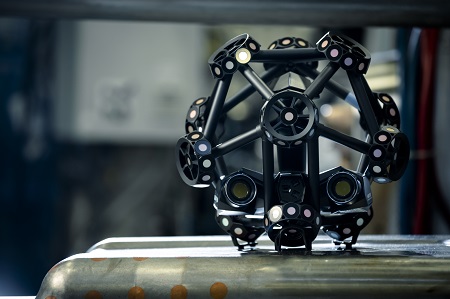

The portable optical CMM scanner include 15 blue laser crosses for larger scanning area that take up to 1,800,000 measurements per second and live meshing, ultimately cutting down the time between acquisition and workable files. It has a measurement resolution of 0.025mm (0.0009 in) to generate highly detailed scans of any object.

MetraSCAN BLACK is declared to have more accurate and traceable measurements with high accuracy of 0.025mm, based on VDI/VDE 2634 part 3 standard and tested in a ISO 17025 accredited laboratory, ensures complete reliability and full traceability to international standards. The machine presents a unique and patented dynamic referencing that compensates for surroundings instabilities.

The optical CMM scanner masters complex, shiny and highly detailed parts. Operators can be up-and-running in minutes. When paired with the HandyPROBE, the MetraSCAN BLACK lets users harness the power of both 3D scanning and probing for a complete, streamlined inspection process. The product is available in BLACK and BLACK|Elite. Customers can choose from two models based on their needs: speed, part complexity, and accuracy.

Digital strategies

As major economies go into various states of lockdown, and people stop leaving their homes, it’s only natural that online traffic has spiked, albeit in certain categories more than others.

Like many companies, Creaform has shifted over to digital strategies where necessary. Patrice explained that this is something their technology is well suited with.

“So far, the market has been very receptive to this new approach. In addition to this, we are very well positioned for the recovery as we have footprint, via branch office or business partners, in all countries in South East Asia. This has even allowed us to continue in person activities, where this has been possible,” he added.

Patrice detailed, “Webinars, web demos, virtual conferences, digital marketing, including social media activities are part of our marketing efforts to ensure the promotion of the new MetraSCAN BLACK.”

Moving forward

Manufacturers must act now to preserve the integrity of their operations, while preparing for the ramping back up of their operations and the future post COVID-19. And while some companies have started responding to the immediate crisis, not all are taking steps to protect their manufacturing, supply chains and operations. And even fewer have started to face the equally important challenge of planning for the new ways of working, which will emerge as COVID-19 infection cases start to decrease significantly.

Since Creaform manufactures products and provide services that support customers in critical industries, such as healthcare research and development, medical devices, power generation, energy infrastructure, and aerospace and defense, they are taking many precautionary measures to mitigate any disruptions with the supply of its products and services. Therefore, the company is moving forward virtually and safely- together!