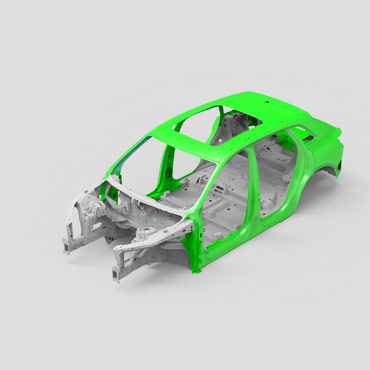

Alumobility, a non-profit organization focused on technical studies to advance the adoption of aluminum automotive body sheet, has revealed the results of its newest study demonstrating that an aluminum automotive top hat, the upper structure of a vehicle's Body-in-White, can save significant weight compared to steel while meeting or exceeding automakers' performance criteria. Introduced at Automotive Circle's annual EuroCarBody conference, the study's aluminum top hat achieved 42 percent weight savings compared to the reference top hat of the current Audi e-tron® electric SUV, which uses advanced (AHSS) and ultra-high-strength steels (UHSS).

Alumobility, a non-profit organization focused on technical studies to advance the adoption of aluminum automotive body sheet, has revealed the results of its newest study demonstrating that an aluminum automotive top hat, the upper structure of a vehicle's Body-in-White, can save significant weight compared to steel while meeting or exceeding automakers' performance criteria. Introduced at Automotive Circle's annual EuroCarBody conference, the study's aluminum top hat achieved 42 percent weight savings compared to the reference top hat of the current Audi e-tron® electric SUV, which uses advanced (AHSS) and ultra-high-strength steels (UHSS).

"Our latest research verifies that aluminum can provide automakers a strong, sustainable alternative to steel for the vehicle’s top hat, which is a significant portion of the body structure," said Mark White, Executive Director of Alumobility. "Further, the aluminum top hat can meet or exceed performance criteria while using the same package space as steel, offering an opportunity for weight savings that translates into improved fuel economy and lower emissions on an internal combustion engine vehicle, or greater performance and range or reduced battery size for electric vehicles."

The study also confirmed that an aluminum top hat would require fewer components and joints than its steel counterpart, helping to reduce the time and cost of vehicle assembly. Additional highlights of the latest Alumobility study include:

• Performance attributes were met or exceeded for various load cases

• Obscuration and entry/egress were maintained

• Latest forming and joining technologies were utilized

Launched in January 2021 by founding members Constellium and Novelis, Alumobility conducts technical studies to help automakers utilize aluminum automotive body sheet to fulfill the promise of a lighter, more efficient, more sustainable mobility future. This summer, ARO, Atlas Copco and Sika joined the association as downstream partners focused on joining technologies that enable the use of aluminum.

Additional details on the top hat study are available at alumobility.com.