High-tech company TRUMPF will take the Blechexpo fair as an opportunity to unveil its "EdgeLine Bevel" solution, which automatically prepares parts for welding during the cutting process. Compatible with standard TRUMPF laser-cutting machines, this technology allows users to create beveled edges while cutting out the contours of each part. Liquid metal flows into these bevels during welding to ensure a high-quality weld seam. On today's shop floors, fabricators typically perform beveling prior to welding using a milling machine, grinding machine or angle grinder – an additional step that is both cumbersome and time-consuming.

Currently, the only way to create bevels automatically is to use technologically advanced machines with specialist 3D cutting heads. However, these are seldom available on manufacturing lines, especially those operated by smaller fabricators. EdgeLine Bevel from TRUMPF is the first solution that allows users to bevel part edges automatically on much simpler, standard types of laser-cutting machines. The technology can also be used to create bevels on a part's inner contours, which are impossible for manual angle grinders to access.

"This is a truly unique way of eliminating downstream processes in the sheet-metal fabrication environment. It boosts the efficiency of customers' production lines and confirms the status of TRUMPF as a solution provider for the entire sheet-metal process chain," says TRUMPF product manager Patrick Schüle.

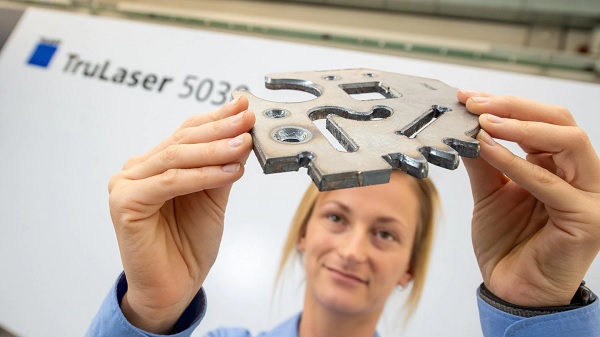

A worker inspects a part after creating bevels using TRUMPF EdgeLine Bevel technology.

(Source: TRUMPF / Martin Stollberg)

EdgeLine Bevel technology allows standard TRUMPF laser-cutting machines to apply slanted edges to the contours of a part in a process known as beveling. (Source: TRUMPF / Martin Stollberg)

A worker removes a beveled part from an off-the-shelf TRUMPF laser-cutting system.

(Source: TRUMPF / Martin Stollberg)