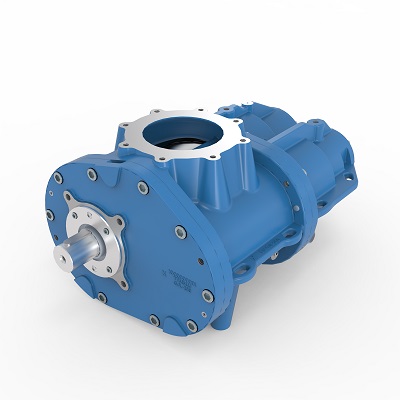

With extreme efficiency and quiet running, the S-4 series really set a before and after in the world of compressed air technology when they were launched. The innovative design concept has now expanded to include additional power ranges, and the oil-lubricated screw compressor with the large housing is also now available where 90 kW power are required. BOGE continues to fulfil its customers’ demands for powerful yet simultaneously efficient, low-noise compressors. The optimised airend with direct drive similarly ensures reliable running.

Best in class, the new BOGE compressor shares the outstanding characteristics of its elder siblings in the S-4 series. The latest model, the S 91-4 with an output of 90 kW is, of course, also the most efficient screw compressor in its class, able to produce excellent free air delivery at low specific power consumption when compared with its competitors.

“Because of the model’s revolutionary construction concept, the efficiency benefits are best achieved, along with the generously sized components that reduce internal pressure losses. In addition, BOGE’s own internally developed airend is capable of achieving high efficiencies,” says Nalin Amunugama, General Manager, BOGE Kompressoren Asia Pacific.

Reliable, low-maintenance operation thanks to the direct drive

The great advantage of the S-4 series is its direct drive on the airend. With its highly robust design, the airend is hermetically enclosed and offers considerable advantages when compared with standard belt-driven models which can suffer from high levels of wear in certain areas of application. “Generally, V-belts need to be replaced two or three times a year,” explains Nalin. This, he says, adds to the cost and is quite a disadvantage when compared to BOGE’s direct drive-based system. When combined with a frequency converter, the speed of the new BOGE compressor can be varied, making it ideal for adapting to the exact compressed air requirements for the task.

Optimum sound insulation and integrated heat recovery

Using vibration isolation for individual components and the flow of cooling air, BOGE has been able to reduce noise considerably, meaning the compressor is ideal for use even in the most demanding of sensitive environments. To make the best use of the energy supplied to the device, heat recovery can also be added optionally to it. This then uses the heat created by the running of the device to warm service water or for other processes.

Future-facing monitoring

For intelligent compressed air management, the modular focus control 2.0 control system and airtelligence provis 3 interlocking control are available to BOGE customers. In combination with BOGE connect, both result in even greater efficiencies, as all of the compressors installed throughout the entire system are controlled and monitored optimally. Maintenance tasks can be planned to reduce downtimes to a minimum. Users are also able to access the system remotely, allowing them to react directly at the first signs of any issues with the device. As a result, BOGE connect ensures increased operating safety, reduced operating costs and prepares the path for Industry 4.0 via its digital interconnectivity options.