By: Kathryn Gerardino-Elagio

Robert Bosch GmbH held its annual press conference via online in early May 2022. The focus of the press conference is on the topics of energy and sustainability. It emphasises how sustainability can be pushed forward using technology invented for life. This also means making life with the transition as easy as possible. Of course, the company also gave an overview of its 2021 business, and what they are offering amid the current challenges.

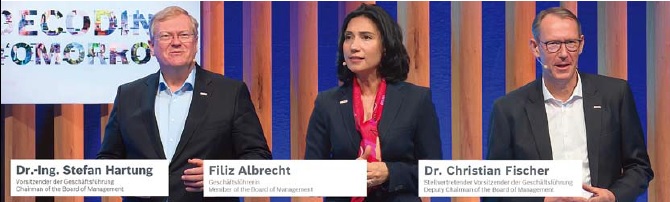

International Metalworking New for Asia (IMNA) attended the live session to hear what Dr. Stefan Hartung, chairman of the board of management, together with Filiz Albrecht, Dr. Christian Fischer, Dr. Markus Forschner, Dr. Markus Heyn, and Rolf Najork, members of the Bosch board of management, have to say. Below are the abridged summaries of the executives’ responses.

Dr. Hartun: Electrification and green hydrogen

Our concern right now is the security of energy supplies, and in many countries, this is leading, at least temporarily, to a new energy pragmatism. In the longer term, however, oil and gas prices will certainly remain on a level that is high, if not very high. While it may be tempting to shift the focus away from climate action in times of international conflicts, there are good reasons to do just the opposite and to work on the technological conditions for mitigating global warming. We firmly believe that this is precisely what Bosch is capable of. The way we see it, we deliver technological solutions to this ecological problem. In this sense, technology that is “Invented for life” is technology for more sustainability on the road, in buildings, and in factories.

For me, it is perfectly clear that if we really want to mitigate global warming, we have to be prepared to accept carbon-neutral technologies in every part of the economy. We still have to make some of these technologies available on competitive terms, and some will have to be developed completely from scratch. To achieve this, we are taking a two-pronged approach.

First, we are opting for electrification. Assuming it uses green electricity, this is the fastest route to climate neutrality. Bosch has solutions for this – both heat pumps for buildings and electrical powertrain systems for vehicles. Second, we are opting for hydrogen and developing the applications for it. Green hydrogen is essential if we want to make our world climate neutral. Contrary to what some people believe, hydrogen is by no means something that only the steel and chemicals industries need. It makes sense to use it in nearly every sector – whether in buildings as a replacement for natural gas, or in order to wean trucks and machinery off diesel.

Bosch wants not only to use hydrogen technology, but also to be one of the companies’ manufacturing it. That’s why we will enter the components business for hydrogen electrolysis by mid-decade. We have a broad basis from which to develop hydrogen technologies, and we are currently ramping up our investments in our core plants. For us, new energy for climate action is also a social mission.

Dr. Forschner: 2021 brought to a successful close

Given the present developments, I will be devoting a lot of my attention to the current business. All business sectors contributed to our positive financial result last year. Mobility solutions increased sales by 7.6%. Industrial technology benefited from the recovery of key mechanical engineering markets, achieving sales growth of 18.9% and an EBIT margin of 8.4%. After a strong showing last year, consumer goods was able to further increase its sales by 12.7%, and again achieved a double-digit margin from operations, at 10.2%. Energy and building technology also performed well, with a 7.8% increase in sales and an improved margin of 5.1%. This is due in part to our success with climate-friendly heating technology.

Now for some remarks on the 2022 business year, Bosch Group sales are up 5.2% for the first three months of the year. The mobility solutions business sector has posted an increase of 4.8%. Two business sectors have grown by double digits: Industrial technology, at 14.4%, and energy and building technology, at 11.7%. We have achieved 1.7% growth in consumer goods. From a regional perspective, sales in the first quarter have grown particularly in Asia Pacific and the Americas.

Mrs. Albrecht: Sustainability has become a core business responsibility

We’re moving just as quickly in addressing climate action along our supply chains. We’re on our way to achieving this target, while making our own business carbon neutral was in itself a big step, we are now reducing our carbon foot-print by twice as much each year, from our suppliers to our customers. Our purchasing department is working to make this happen, as is every one of our divisions. There are three levers over which we have immediate control: first, more circular economy; second, more energy efficiency in our existing products; and third, shifting our product portfolio toward climate-neutral products. Climate action isn’t something we aim to do alongside or on top of our business – we are making it our business.

Dr. Fischer: More than one way to transition to alternative heating in buildings

Whether in buildings or on the road, we embrace the principle of electrification first. In concrete terms, this means that the transition to alternative heating starts with the heat pump, ideally powered by green electricity. Market developments are clearly pointing in this direction. This year, the value of the heat-pump market in Europe has caught up with that of the gas-fired boiler market. It will expand by an annual 15 to 20% between now and 2025, and we want to grow at twice that rate – by between 30 and 40%. To achieve this, over the last four years we have invested €400 million, and we will invest an additional €300 million by mid-decade. Investment gives rise to innovation. We have developed a solution for integrating heat pumps into home energy management and thus also for running them in partial-load mode as needed. This lowers both electricity consumption and noise, making it easier to live with the transition to alternative heating.

Mr. Najork: Industrial technology is driving electrification

It is precisely in industrial manufacturing, where rationalisation originated, that it has to prove possible to combine economic and ecological objectives. The energy and cost-efficiency equation are, in fact, driving climate action in factories – and digitalisation is a crucial element here as well. Thanks to connected energy management alone, we are reducing the annual energy consumption of our manufacturing operations by an average of 5%. The energy platform from our Industry 4.0 portfolio is already in use in 80 customer projects and at 120 Bosch locations. Adding artificial intelligence generates even more efficiency. For instance, our plant in Changsha, China, developed an AI-controlled energy management system that enabled it to reduce its annual energy consumption by 18 percent. That’s reason enough for the World Economic Forum to honour Changsha as a global lighthouse for Industry 4.0.

Dr. Heyn: Alternative mobility also means electromobility plus fuel cells

The market for electric vehicles is gaining momentum. All automakers are eager to secure the greatest possible share of this market. Bosch sees itself as the number one supplier for electrical power-trains on the road as well. We are doing all we can to make electromobility even more practicable. In the same period, we will invest half a billion euros in stationary fuel-cell technology. Bosch is positioning itself broadly here as well – we are thinking beyond mobility. Stationary fuel cells are typically used in micro power plants, or to supply electricity to data centres or city districts. Production is being ramped up in our core plants – in Bamberg, Homburg, and Wernau. We plan to launch stationary fuel cells on the market in 2024. In order to tap the Chinese market, we are also planning a joint venture with our partners Ceres Power and Weichai.