The new Microcell Technology from Promix Solutions, company engaged in physical foam extrusion using environmentally friendly blowing agents CO2 and nitrogen, will reduce raw material consumption in extrusion processes by up to 20% without losing mechanical properties. Until now, the density reduction in physical foaming contributed to a certain loss of mechanical properties. This recent breakthrough has changed this and makes the technology even more attractive.

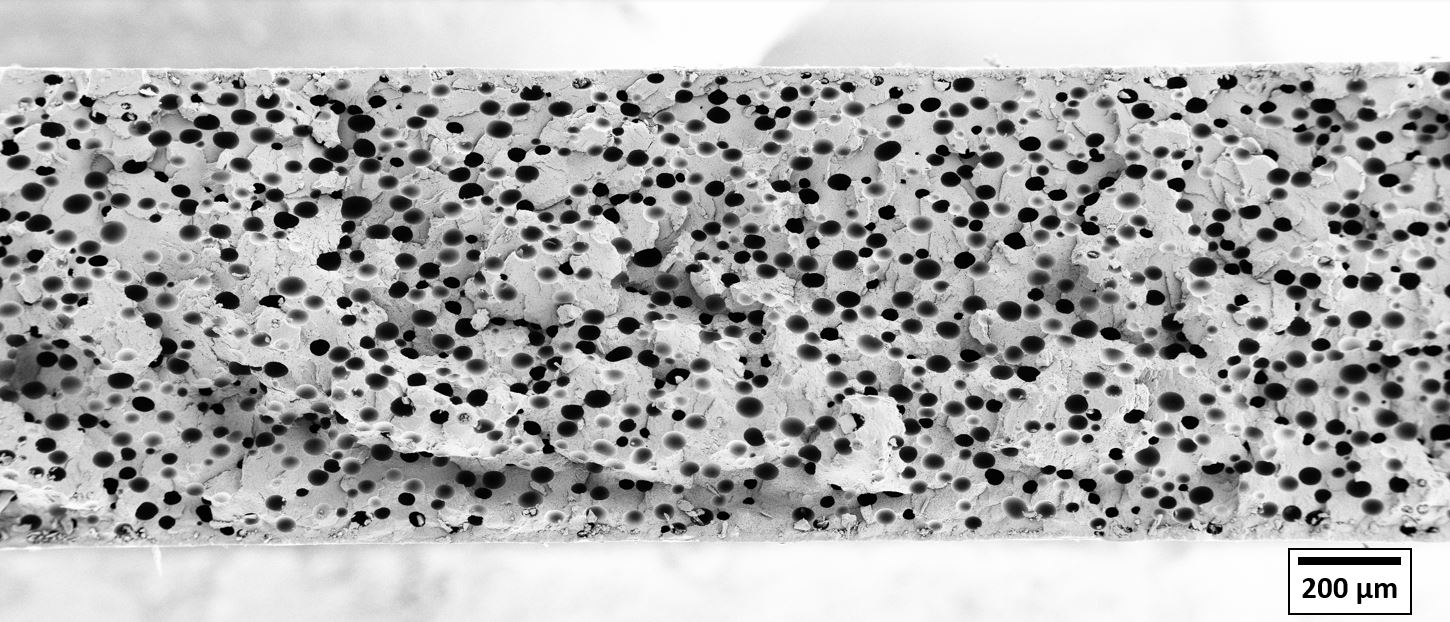

The secret of high-quality physical foaming lies in the cell structure. Tests have shown that very small and evenly distributed cells result in significantly improved mechanical strength. A foam with 50 μm cell size has 27 times more cells than a foam with 150 μm cell size (same density). This fact makes it understandable that the mechanical behaviour of microcell foams is different. The key to achieve the small cells is a combination of various factors. The dispensing of the blowing fluids with very high precision and in supercritical stage, unique cooling and mixing equipment, special nucleation technology and further improved process knowhow was required to achieve the next level of foaming.

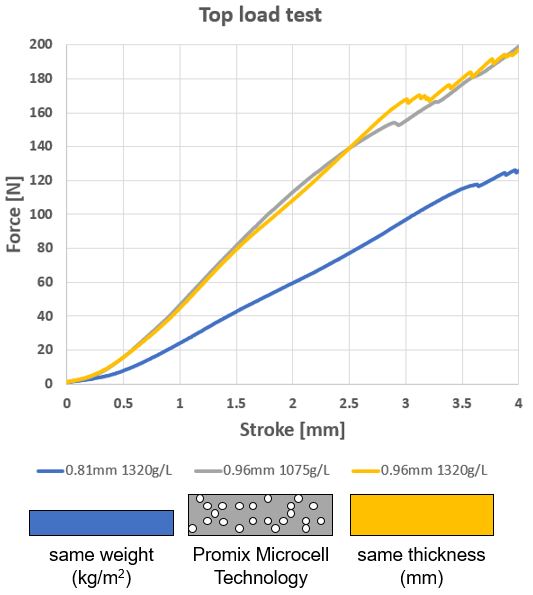

The example above illustrates the new potential. The thermoformed PET tray foamed with Promix Microcell Technology (grey) shows the same mechanical top load properties as a solid tray (yellow) but is 18% lighter. The non-foamed benchmark tray that is also 18% lighter (blue) shows however significantly reduced top load properties. This example documents that the Microcell Extrusion Technology is an effective way to save up to 20% raw materials without compromising mechanical properties and is in addition reducing energy consumption and environmental footprint. The internal and external recyclability remains 100 % intact and is equivalent to the non-foamed products.

Promix Microcell Technology works for all types of extrusion processes including packaging films, sheets and boards, pipes and profiles, cables, blown film and extrusion blow moulding. The technology can be retrofited to existing extrusion lines as well as installed in new lines. Promix is working with a number of machine builders to achieve a perfect match.