The pandemic has not been kind to automotive sector. In a recent report, French automotive data and market research company Inovev projected that global automobile production will fall by 17% over the whole of 2020, representing a loss of 15 million vehicles compared to 2019 and returning volume to 2011 levels. But there still are signs of hope and optimism. China, for example, reopened its auto-making facilities sooner than those in other nations, and countries such as Japan and South Korea were less affected overall by the pandemic. Additionally, the growing trend towards electric vehicles (EVs) and self-driving autonomous (and semi-autonomous) vehicles is creating opportunities for new and expanding applications for a variety of advanced plastic and composite materials.

In the U.S., Pete Buttigieg, President-elect Joe Biden’s nominee to be secretary of transportation, has declared that he wants to help put “millions of electric cars” on U.S. roads. Such growth will help to further drive sectors such as the polymer-intensive automotive radar market, which is projected to reach US$12.2 billion by 2025, growing at a compound annual growth rate of 20.8%, according to Grand View Research Inc.

In a recent interview with Sustainable Plastics magazine, Yanfeng Automotive Interior Systems Co. Ltd.'s Jeff Stout stated: “Some time, in the not so distant future the interior will look completely different and the use case will be completely different, but it will still all be plastic.” Stout, the firm’s executive director of global Innovation, says Yanfeng practices design for disassembly where possible, is looking closely at chemical recycling, and continues to develop alternate options, such as its Compression Hybrid Moulding (or CHyM) process, in which the primary matrix is a natural fibre mat.

EVs and hybrid vehicles require lightweight, durable, high-temperature-resistant plastics, as well as technology for moulding integrated electronics into the growing number of touchscreens and embedded lighting options that are finding use in interior cabins. Let’s look at a few examples.

Mono-material headlamp

Germany-based Covestro AG has adopted a mono-material strategy, combined with multi-shot moulding and in-mould assembly, to develop a multifunctional vehicle headlamp with numerous benefits. The new design concept cuts the number of components from more than 50 to five, is significantly less expensive to manufacture, weighs less, and is more sustainable than current models. It involves extensive use of polycarbonate (PC), including the firm’s Makrolon TC 8030, a high-end, thermally conductive PC. This enables the replacement of aluminum heat sinks with the moulded material. Each resulting headlamp assembly can weigh nearly 4 pounds less than current, traditional models.

Covestro says it developed this new design concept initially with electric vehicles in mind, because polycarbonate can be susceptible to various chemicals and oils that exist in internal combustion (IC), gas-powered engines. The company continues to work on ways to protect the back of the module from chemical exposure, which would enable the new headlamp design to function equally well with IC engines.

VW goes lightweight

Volkswagen of America’s polymers laboratory near the company’s Chattanooga, Tennessee, plant is working to create innovative solutions to help make cars lighter and more fuel-efficient. “We have to incorporate lighter parts to help offset the weight of the car’s heavy [lithium] batteries,” says VW laboratory evaluation specialist Ellen Collins. “We believe that polymers are the future … and hope that all car companies are taking the same approach because the sooner they bring down the weight of their vehicles, the quicker we can work toward reducing our carbon footprint.”

The company notes the lab recently had success working with suppliers on producing a lightweight polypropylene to incorporate on the door frame of the Volkswagen Atlas. “We were able to reduce the weight of the part while preserving its same characteristics,” Collins noted.

Composites aid the cause

Continental Structural Plastics Inc. (CSP), along with its Japanese parent company Teijin Ltd., recently unveiled an advanced, multi-material EV battery enclosure that can be moulded in any number of CSP’s proprietary composite formulations, as well as a new honeycomb Class A panel technology.

CSP’s multi-material electric vehicle battery enclosure is 15% lighter than a steel battery box. Although it is equal in weight to an aluminum enclosure, CSP says this enclosure offers better temperature resistance than aluminum, especially when used with its own, proprietary phenolic resin system.

CSP says it currently is in development and production of more than 34 different electric vehicle battery box covers in both the U.S. and China.

Separately, the company has developed a new honeycomb manufacturing process that produces ultra-lightweight Class A panels. Considered a “sandwich” composite, these panels use a lightweight, honeycomb core, clad with natural fibre, glass fibre, or carbon fibre skins that are wetted with polyurethane resin. This process enables the moulding of complex shapes and sharp edges, and results in panels that offer very high stiffness at a very low weight.

Radar-absorbing compounds

SABIC has unveiled two new, radar-absorbing LNP™ STAT-KON™ compounds for automotive radar sensors, significantly expanding its portfolio of these specialty materials. The new grades –– based on polybutylene terephthalate (PBT) resin –– may be used for integration with radomes manufactured using PBT material, which can provide superior resistance to automotive chemicals.

They complement and extend SABIC’s existing radar-absorbing LNP STAT-KON compounds, which are based on polyetherimide (PEI) resin for withstanding higher processing temperatures or on polycarbonate (PC) resin for general applications that require high durability and a balance of physical properties. The high radio frequency (RF) absorption of these compounds can help increase detection range and improve signal resolution.

Radar sensors are widely used in advanced driver assistance systems (ADAS), where they provide capabilities such as blind spot detection, collision avoidance, automatic braking and traffic alerts. Radar-absorbing materials (RAM) are used to shield the field of radar wave transmission and attenuate side waves that can cause ghost images or trigger false actions or alarms.

BASF’s mobile charger

Germany’s BASF, meanwhile, also is striving to apply its materials to creative solutions related to the EV sectors. The company says it partnered with two Japanese firms –– ZMP Inc. and B & Plus –– to create a conceptual autonomous wireless charger that aims to meet increasing demand for charging infrastructure solutions. BASF says its Ultradur polybutylene terephthalate (PBT) and Ultramid polyamide (PA) are used in the mobile charger’s radar housing, lidar sensors, protective films, and other electrical components and devices.

More than 75 billion connected devices — such as phones and electric vehicles — are expected to need charging by 2025. Dr. Hisashi Taniguchi, founder and CEO, ZMP Inc., said “MobiPower enables us to meet this market demand, with a convenient charging solution that is robust enough to house sophisticated components and sensors combining 5G, IoT, and AI capabilities, as well as being durable enough for the outdoors. BASF expanded my creativity and the possibility of our robots.”

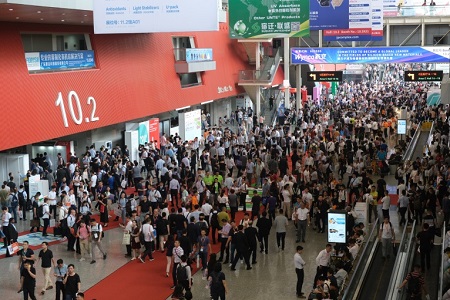

See more of these types of material innovations at Chinaplas 2021 in Shenzhen next April 13-16. Come see first-hand some of the amazing technologies that are helping to enable the vehicles of tomorrow. For more information, visit: www.chinaplasonline.com