The new iQ hold control assistance system determines optimum holding pressure times, enhancing efficiency in setup and production.

ENGEL, a global leader in injection moulding machine manufacturing and system solution providing, is set to exhibit challenging applications at Chinaplas 2023, which will take place in Shenzhen, China, from 17 to 20 April 2023. ENGEL's four machine exhibits will be accompanied by Expert Corners dedicated to trending themes. ENGEL will showcase how combining an ideal machine with smart digitalisation can maximise overall efficiency, and introduce the new iQ hold control assistance system in its Asian premiere.

The demand for productivity and energy efficiency has increased, and integrated system solutions for cost-effective injection moulding are becoming increasingly significant. ENGEL's President for Asia and Oceania, Gero Willmeroth, stated that the company is looking forward to finally re-establishing personal contact with its customers, partners, and the sector as a whole in Asia.

At Chinaplas 2023, ENGEL will use a servohydraulic duo 2460/500 injection moulding machine to produce mirrors for head-up displays.

ENGEL's exhibits at Chinaplas will feature high-precision moulding, automated production cells, compact and energy-efficient machines, and ample flexibility for insertion processes. ENGEL's coinmelt coining process and dual-platen clamping unit will produce polycarbonate mirrors for head-up displays, which require the highest precision moulding to project a sharp display image on a vehicle's windscreen. The convex head-up mirrors underline the high potential in this area. ENGEL will present an automated production cell, and a local partner, Skymold, based in Ningbo City, China, will team up with ENGEL to ensure cost efficiency and shortened delivery times for the system.

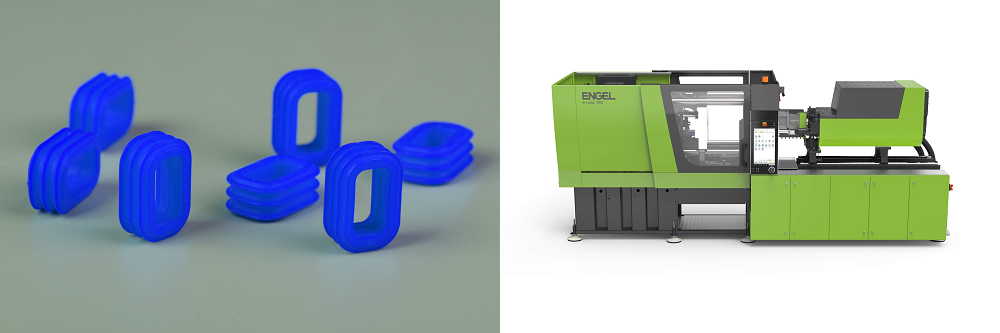

ENGEL will also showcase two applications on all-electric ENGEL e-mac injection moulding machines to demonstrate how productivity gains can be achieved in a highly cost-effective manner. The e-mac 465/180 with a 128-cavity mould will produce connector seals needed in automotive electronics, and the e-mac 1340/280 injection moulding machine will produce blood collection tubes of PET from a 64-cavity mould.

The 128-cavity mould for the production of connector seals will be installed on a highly compact e-mac injection moulding machine.

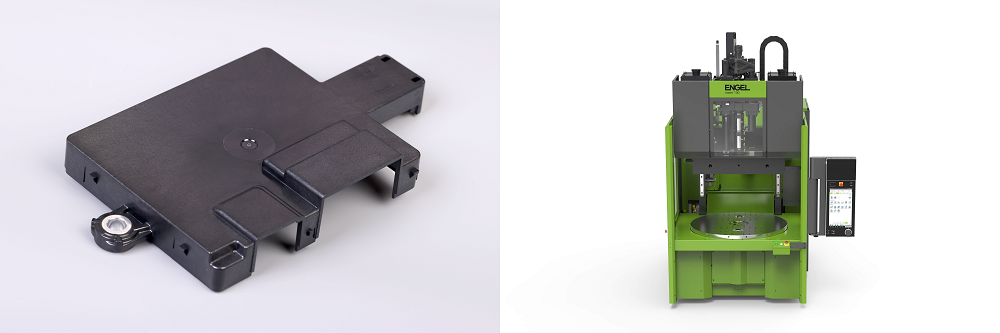

Moreover, ENGEL's vertical machine will produce battery housings from fibreglass-reinforced PC-ABS on an insert 500V/100 rotary vertical machine, with metal rings inserted into the mould and overmoulded. The ENGEL vertical machine offers ample flexibility in connection with insert processes, and a clamping unit that is freely accessible from three sides makes process automation simple. At the same time, the low construction height is highly ergonomic.

Battery housings will be manufactured using an ENGEL insert 100 at Chinaplas 2023.

ENGEL's exhibits at Chinaplas 2023 demonstrate its commitment to maximising overall efficiency and productivity gains in highly cost-effective and energy-efficient ways.