Electric vehicles are gaining strong momentum in the automotive market. High growth rates in new registrations are already driving the cable and wire industry to invest in ever more modern technology. Electromobility is undoubtedly electrifying suppliers.

Audi Hungaria has already started series production of electric motors. Photo: AUDI AG

The AlixPartners analysis reveals “that investment in electromobility will grow much faster by 2025 than expected last year”—globally by plus 41 percent, and in Europe by plus 52 percent. In addition to the ecological aspect, the promotion of the switch to electromobility by governments is also likely to play an important role. 14 EU countries and China plan to ban the sale of internal combustion vehicles by 2035 at the latest, the “AlixPartners Global Automotive Outlook 2021” points out.

Cables of higher quality

The right “cornering stability” will be decisive for the future development of suppliers. Because the cable, wire and tube industry have to take into account that, for example, the exhaust and fuel system, the combustion engine and the low-voltage electrical system are not required for the less complex electric drive. Nevertheless, the prospects are lucrative. In the wake of electromobility, more and higher-quality cables are on the shopping list of car manufacturers. The component is required in the charging cable from the charging station to the vehicle system and from the charging port to the battery. Cables transport the current via the inverter to the electric motor. The interior wiring supplies power to other high-voltage components, such as air-conditioning compressors or electric heating and cooling. Powerful wires and cables are needed to keep vehicles from sputtering. However, as high-voltage cable production continues to grow, it is unlikely to be profitable without further automation and specialised machinery.

Huge market potential

“The market potential is huge,” Wafios also emphatically points out. That is why the company, which develops, designs and manufactures machines for the wire and tube processing industry as well as for cold forming, is accelerating its transformation in the field of modern drives by investing ten million euros in a new e-mobility campus at their former Südwerk site in Reutlingen, Germany. In the future, Wafios' electromobility activities will be bundled in the 1,800-square-meter campus. “Machine development, the customer centre up to the production of prototype and sample parts as well as the commissioning of customer machines will be under one roof in the Campus in the future,” the company emphasises.

Complete production lines

Also, Wafios is forging a new alliance: With the machine manufacturer Gehring, the company is pooling know-how “in order to jointly offer the global automotive industry complete turnkey production lines for hairpin stators,” explains Wafios. In this way, Gehring's experience in designing systems for automotive series production and Wafios' technology in the field of straightening technology and wire forming, which is particularly important for the production of hairpins, will be combined. The fast pace of high-volume production, with electric motors being built in sub-minute cycles, poses a high challenge for stator manufacturing and its very complex wire-bending processes according to Wafios. The cooperation could offer “efficient, process-capable and future-proof end-to-end solutions”. The aim is to transfer existing technology to mass production and also to improve the efficiency of electric motors.

The company Trumpf is also experiencing electromobility as a growth-promoting stimulus. A central role is played here by a laser whose development the laser specialist has pushed as part of its e-mobility strategy and which, according to the company, is proving to be very suitable for welding copper. Copper is considered the most important material for conducting electricity and is indispensable in an electric car. The laser can be used to efficiently weld copper for the high-performance electronics of electric cars. “The shift toward electromobility offers great opportunities for the German industry,” emphasises Christian Schmitz, Managing Director for Laser Technology at Trumpf. The company expects further growth for its own business as a result of the transformation of the automotive industry.

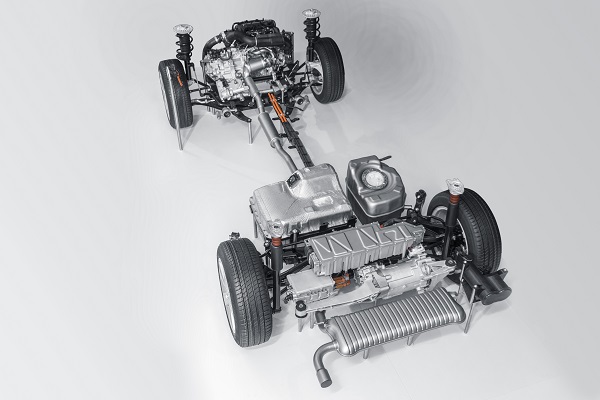

A look at the powertrain of the BMW 225xe. The electric motor of the plug-in hybrid vehicle BMW 225xe iPerformance has won the Bavarian State Prize for E-Mobility. Photo: BMW Group

Increasing demand for cables

The breakthrough of e-mobility is leading to a rapidly increasing demand for high-voltage cables. Manufacturers of on-board electrical systems are looking for ways to “automate the processing of these complex, multi-core cables with additional shielding,” explains DiIT, a manufacturer of software solutions for manufacturing execution, KSK production and logistics. In their view, in addition to throughput, automatic quality control also plays an important role. Therefore, the standardisation of interfaces is “finally picking up speed”.

In principle, manufacturers of wire processing machines are still defining their own interface specifications. “The integration of machines into an MES system therefore involves considerable effort in most cases.” The times of proprietary interfaces should also be over for good in the cable processing industry. For this reason, a VDMA working group was formed at the end of 2021 with the goal of developing an industry standard based on the OPC/UA industry standard.

Continuous digital twins

Many manufacturers of on-board electrical systems are already working with digital twins. They are used at almost every stage of the engineering and manufacturing process. “What has been missing so far, however, is continuity. Each stage uses its own digital twin, independent of the others,” explains DiIT. In order to enable continuous traceability and quality assurance, however, the information model of an on-board electrical system must be applicable across all stages—from engineering to installation and ideally even to the use of the on-board electrical system in the vehicle. “In the ARENA2036 research campus, an innovation platform for the mobility and production of the future, renowned vehicle manufacturers, cable assemblers, machine manufacturers, software houses and other companies have now joined forces to advance continuous digital twins.”

Products and processes are changing

The changes associated with the switch from combustion to electric vehicle technology are therefore fundamental and affect products and processes. Also, “competencies such as blow moulding, pipe extrusion and machining technology are losing importance, while processes such as coiling and forming technologies for parts made of aluminium and magnesium are gaining,” explains the VDA (“Association of the Automotive Industry”). To continue on the road to success, the wire and cable industry must therefore steer flexibly in the right direction. Then it heads for high profits at full throttle.