Titanium is a challenging material in terms of machining technology. Not all types of titanium are the same. Depending on if the material is pure titanium or alloyed titanium machining behaviour varies. Therefore, Mikron Tool has developed perfectly tailored drills for the respective titanium grades, which guarantee high cutting values, process reliability and excellent hole quality.

Machining the unruly titanium is highly demanding. One of the reasons is the combination of its properties of high elasticity and tensile strength. Because of the high toughness, chip breaking is difficult to realize. Due to its low thermal conductivity, heat is not dissipated from the cutting zone through the chip. In addition, titanium tends to form built-up edges. This all leads to higher wear and reduces process reliability during drilling.

And drilling in titanium is much more challenging than milling. The viscoelastic property of titanium causes the drill to stick, and the pressure on the cutting edges increases. This usually leads to uncontrolled drill breakage. Material sticking on cutting edges and guide chamfers increase cutting forces, because of which the cutting edges can break out. Moreover, the chip shape is also problematic. This is because the titanium chips tend to compact in the head area and prevent further chips from flowing in. The high temperature load on the cutting edges is an additional complicating factor.

To reduce the heat in the cutting zone, the cooling lubricant must reach the machining zone directly. Two cooling channels with very large cross-sections carry massive amounts of coolant to the drill tip and guarantee constant cooling including lubrication of the cutting edges. At the same time, the massive coolant jet flushes the chips through the polished flutes and prevents chip jams. The patented special shape of Mikron Tool's cooling channels enables a 4 times higher volume of coolant to be shot through the tool at the same pressure.

But that is not all. “Not all titanium is the same,” says Markus Schnyder, President of Mikron Tool International. “If you want to machine this material efficiently, you must know it down to the smallest detail. In our development work, we examined various test materials and discovered that the different grades of titanium are extremely different from each other, which is of utmost relevance for their industrial machining. Pure titanium (grades 1-4) is characterized by high corrosion resistance but has lower mechanical strength. Alloyed titanium (grade 5 and higher) has high strength but low ductility. Getting to grips with these differences in terms of machining technology is a stroke of genius.”

“Our passion and the knowledge gained brought us - as of today - a perfect solution: two specific geometries, one for pure titanium grades and one for titanium alloys. In this way, we guarantee perfectly controlled chip removal, high drilling speeds and repeatable processes with optimum drilling quality for these difficult titanium materials,” adds Schnyder.

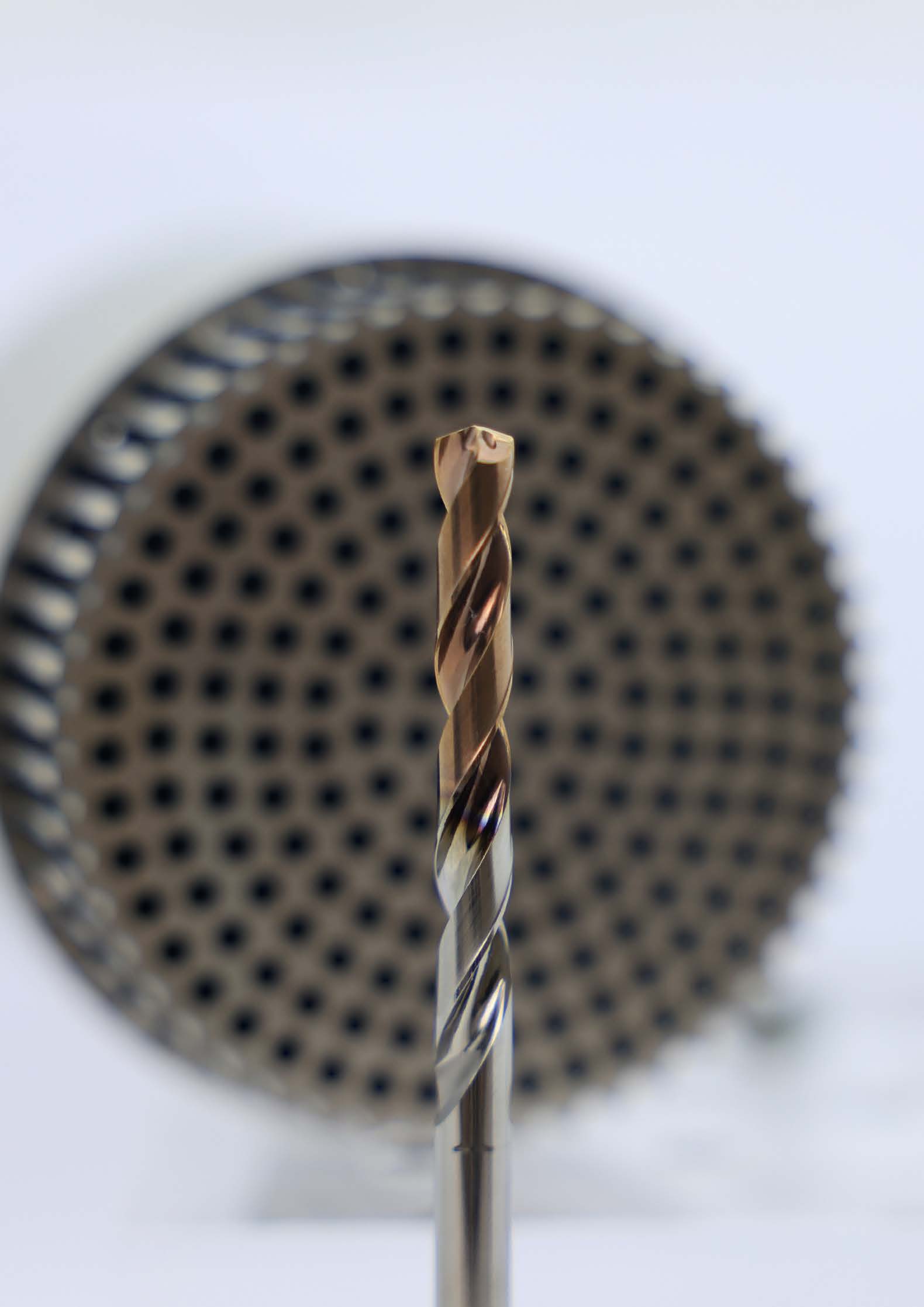

The new Crazy Drill Cool Titanium series (ATC for alloyed titanium and PTC for pure titanium) is offered in the diameter range of .039" – 1/4" (1 - 6.35 mm). For pure titanium, Mikron Tool developed short drills with 3 x d and drills with 6 x d. For titanium alloys, Mikron Tool relies on drills with 6 x d and 10 x d in combination with a pilot drill.

New high-performance drills for titanium

Drilling titanium is highly demanding. One of the reasons is the combination of its high elasticity and tensile strength. Because of its high toughness, chip breaking is difficult to realize and due to the low thermal conductivity of titanium, heat diffuses directly into the tool. In addition, titanium tends to form built-up edges. This all leads to higher wear, low surface quality and insufficient process reliability. In addition, not all titanium is the same. Depending on the pure or alloyed titanium, very different machining behaviour results. Mikron Tool responds to this with two new product developments: CrazyDrillCool Titanium PTC for pure titanium, and CrazyDrillCool Titanium ATC for titanium alloys.

These drills, which are perfectly matched to the respective titanium grades, achieve maximum drilling performance combined with high process reliability. It is now even possible to drill titanium alloys up to 10xd in a single step without multiple pecking for chip removal.

1) Different properties of pure titanium and titanium alloys: The material properties of pure and alloyed titanium differ significantly, which is of utmost importance for their industrial machining. Especially for drilling, the demands on the tools in terms of machinability are very high. Mikron Tool's solution for drilling the different types of titanium consists of two material-specific cutting-edge geometries. This is the only way to achieve controlled chip evacuation, high drilling speeds and repeatable processes with excellent hole quality can be achieved.

2) High temperature load and chip jam: When drilling titanium, the high temperature load on the cutting is a challenge. This can lead to micro-chipping and ultimately to cutting edge chipping. In addition, titanium chips tend to compact in the head area and prevent further chips from flowing out. The result is uncontrolled drill breakage. The solution is innovative cooling concept. Two specially designed cooling channels with a very large cross-section guide massive amounts of cooling lubricant to the drill tip to prevent excessive temperature loads on the cutting edges. The patented special shape of the cooling channels enables up to 4 times higher coolant quantity (compared to conventional cooling channels) at the same pressure. At the same time, the massive coolant jet flushes the chips through the flutes and prevents any form of chip jam.

3) Material adhesion: Material adhesions on guiding margin and the secondary margin have a negative effect on the hole quality. The solution is guiding margin and the newly designed chip barrier margin. The particularly smooth surfaces of the guiding margin and the newly designed chip barrier margin on the PTC drill prevent material sticking and reduce the load on the tool.

4) Tool jamming with increasing drilling depth: As the drilling depth increases, the extreme viscoplasticity of the titanium leads to jamming of the tool. The consequence is tool breakage. The solution is a special cutting-edge geometry with optimum cutting ability and stability. The answer is sharply ground cutting edges that must be stable at the same time - a contradiction in terms. For the titanium drills, a unique specific cutting-edge geometry was developed that masters this balancing act. As a result, cutting pressures and temperature are significantly reduced.

5) Position accuracy: Due to the viscoplastic material properties of titanium, a precise entry point and constant tool guidance during drilling cannot be guaranteed. The response is specific pilot drill to achieve high position accuracy, the new pilot drill (with 90° chamfer) CrazyDrill Coolpilot Titanium ATC can be used.