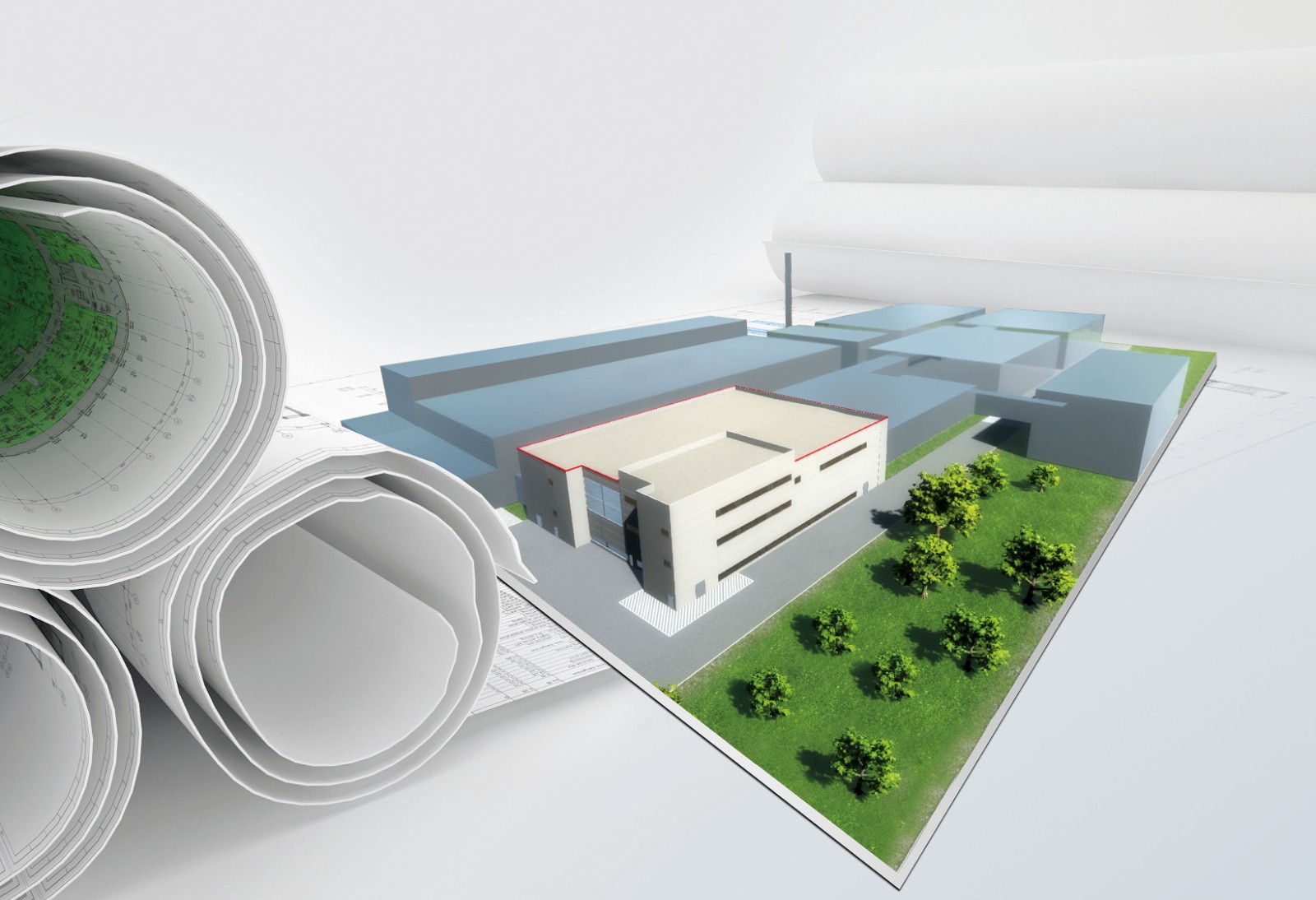

planetary SA has started the engineering phase of its first industrial scale bio- and food tech production hub in Switzerland. The overall engineering work is led by Dr. Joachim Schulze, CTO, planetary. Planetary’s production facility is designed to be a first of its kind multi-product microbial fermentation facility, able to produce precision fermented compounds, such as proteins and lipids, as well as biomass from mycelium on a commercial scale. This is the key to lowering costs of alternative protein and generating a measurable impact on world food production.

planetary SA has started the engineering phase of its first industrial scale bio- and food tech production hub in Switzerland. It will provide third parties with microbial bioprocessing capacity to scale the new food evolution, sustainably.

Conventional agriculture is reaching its limits with regards to natural resource utilization and is a major contributor to man made GHG emissions. This plant will be the first of many planetary owned facilities around the globe, aimed at providing critically needed microbial bioprocessing capacity for third parties to scale the new food evolution, sustainably. Benefits will be the mitigation of global warming, reduction of water and land consumption related to food production as well as a minimised output of greenhouse gases.

Glatt Ingenieurtechnik will plan the process technology systems, including media supply, process control and automation, as well as the safety technology. IE Group, Lausanne office will design the building and facility infrastructure. The planning team, led by Glatt, will use an integrated engineering approach, applying cross-trade 3D CAD planning, coordination and Building Information Modeling (BIM) with a focus on sustainability and resource efficiency.