SEKISUI Polymer Innovations, LLC, a global thermoplastics leader that serves a diverse spectrum of major industries including aviation, transportation, and medical devices, was looking for a strategic partner for quality control to improve service to their focus markets and maintain their leading role in manufacturing. The company invests heavily in cutting-edge technology and they were looking to bring more automation and consistency to the workflow.

Meeting the challenges with the right solution

Renowned worldwide for the high quality of its products and services with focus on niche market, SEKISUI SPI is among the few thermoplastic sheet manufacturers that can accomplish small run sizes within very short lead times. Majority of the company’s customers are from the public transportation and medical sectors. They demand top quality products with tight color specifications that are typically small in order size and time sensitive.

SEKISUI SPI has more than 5000 different color standards. The colors specified by customers can have very minor fluctuations within provided requirements. The inability to predict how reheating plastic sheets will affect the color and gloss properties make color matching even more challenging. Getting the color right on the first try is critical when working with small customer orders that need to be delivered quickly.

Datacolor worked closely with SEKISUI SPI to implement a solution that improves the color management workflow and speeds up the decision making process. As a result, SEKISUI SPI is able to deliver high quality products with faster turnaround, staying ahead of their competition. The Datacolor solution enables SEKISUI SPI to achieve consistent and repeatable measurement of color standards month after month, and develop accurate color formulation that meets stringent government regulations. As it is simple to learn, implementing the user-friendly system is easy and can be integrated into the workflow. SEKISUI SPI's aviation dedicated facility – South Campus – is fully equipped with Datacolor instruments to measure specialty colors.

“Our design team is very happy with Datacolor's performance on colors that are very common in the aviation industry. We feel we can get more accurate readings and reach the conclusion faster,” says Jeff Humenick, Plant Manager SEKISUI SPI's South Campus. “Datacolor solutions are straightforward and easy to use. SEKISUI SPI's new employees trained on the equipment are quickly able to learn how to use the machines, becoming effective and productive users in very little time.”

Another Datacolor advantage is its excellent service and timely support for SEKISUI SPI. Phil Ruggiero from Datacolor was the applications engineer who ensured the installation went well and all deadlines were met. Sean Thornton, Datacolor's agent in the Northeast USA, supported the project from the beginning acting as a liaison between SEKISUI SPI and Datacolor Sales & Support.

The right color management solution from Datacolor

Commitment to excellent service, speed, and superiority has earned SEKISUI SPI the leading position in the markets it serves. Datacolor plays an important role helping SEKISUI SPI achieve its goals through its color management solutions.

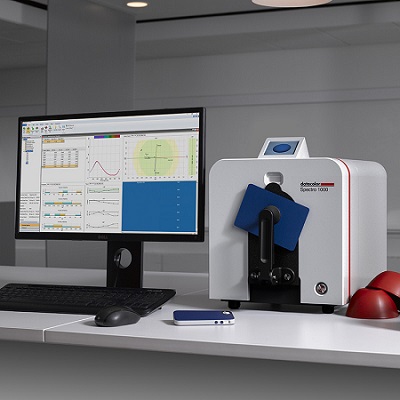

Datacolor's highest precision benchtop Spectrophotometers within the Spectro 1000 Family are designed for high efficiency and confidence in color formulation and quality control in textile, plastics, paint, coatings and more. When high precision and close tolerance are required, the Datacolor Spectro 1000 benchtop Spectrophotometers can be trusted to specify, formulate and control the colors of choice. Four configurations of the Spectro 1000 are available to support any application: the standard front facing Spectro 1000; vertical downward facing Spectro 1000V for unusual samples as well as for operations requiring high throughput; vertical upward facing Spectro 1000X that is ideal for liquid, paste, powder and granular samples; and flexible Spectro 1050 for measurement in either reflectance or transmittance mode.

The Datacolor Pigment Formulation Software is another solution designed to bring ease to the work of professionals in the paint, pigment and plastic industries. Its Match Pigment software amplifies the accuracy of color development, improving quality control and productivity. This sharp color matching software fine-tunes formulations using two high-level features to produce vivid results. SmartMatch technology analyzes the approved formulations to boost first-shot match rates, and Gamut Mapping solves common colorant challenges by speeding up the color formulation process.

The Color Quality Control Software as part of Datacolor Tools is designed for designed for color development and quality control specialists in the textile, automotive, paint, plastic, ink, paper, cosmetics and other industries, Datacolor Tools enables objective analysis, reporting, communication and visualization of accurate color results.

For more information, visit: www.datacolor.com