HCI Converting Equipment Co., Ltd. has excelled in the global market that requires great flexibility, with a belief in effectively meeting the widest range of needs in the flexible packaging market and practical experience for over 40 years. As a professional manufacturer of bag making, slitting, laminating, and rewinding machines, HCI has followed the global trend of "circular economy" and continues to collaborate with customers in 108 countries to develop more efficient, economical, and environmentally friendly packaging and sealing innovation. HCI expects to gradually replace some of the current heterogeneous packaging materials with "Single-Component Based Multi-Layer Film ", leading customers to a new future of 100% recyclable flexible plastic packaging.

HCI bag-making equipment is in sync with Sustainability Trends, solving precise “melting point" and "sealing pressure" control challenges

Highly recyclable single-component based multi-layer film alternative solutions have gradually emerged in recent years and are now being used in instant food, frozen packaging, medical, toy, and other packaging applications. The majority of the early single-component based multi-layer films are based on PE and PP, and chemical major players such as Dow and Borouge have all announced their commitment to the development of this new material. Even as early as at the K-Show 2019, European plastics majors are scrambling to enter this potential market in response to the EU's 2030 plastic reduction target. On the other hand, relying on years of hard work in customization, HCI has successfully developed and adjusted the mechanical structure and control system of the bag-making machine to lead customers to adapt to the bag-making process of this new generation material.

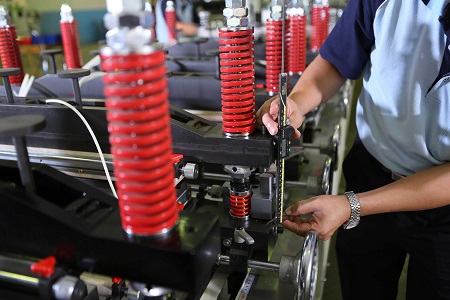

Because the melting point temperature of the inner and outer layers of single-component based multi-layer film is similar, the traditional high-temperature sealing process may cause the inner and outer layers to melt through, or the sealing area to be severely wrinkled. As a result, especially in the temperature sensing part, manufacturers must perform more precise temperature control and achieve better temperature uniformity. Also, the pressurized sealing process, which used to be relatively simple, now requires a very subtle and even pressure adjustment. After going through the Bottom Folded, Ultrasonic for Zipper Sealing, Cross Sealing Section, Punching Unit, and other processes, manufacturers can finally start the mass production of the easy-to-recycle Three Side Seal Bag, Stand-Up Pouch, and Zipper Pouch out of the single-component based multi-layer film.

The use of single-component materials for mass production poses a significant challenge. Manufacturers must meet common food packaging requirements such as light-blocking, airtightness, water resistance, printing, sealing, and so on, all while balancing yield rate and capacity. The significant difficulty, however, deters many common equipment manufacturers. HCI has the technology and experience to compensate for the lack of material properties as the process approaches the limits of the supplier of materials' control, can assist customers in entering international markets with ease by providing precise temperature control, temperature equalization, and mechanical adjustments to meet new environmental requirements and regulations.

"Circular Manufacturing" and "Easy Recycling" - New Flexible Packaging Trends

Although there are many unresolved issues in the food and medical packaging fields with single-component material packaging, "increasing the recycling rate" and fulfilling "zero waste" are excellent starting points and goals; as the old saying goes, "we are not afraid of the long way if the direction is right." Starting from the European Union, the United States, Japan, China, and Taiwan are actively responding by developing recycling policies. HCI is working with its customers in the hope that the international community will be able to create a sustainable environment in the near future.

For more information, contact:

Mr. Terence Chen

E-mail: terence@hci-tw.com.tw

Website: https://www.hci.cc/