As a global leader in bag-making machines, HCI Converting Equipment Co., Ltd. has been selected to represent TaipeiPLAS 2022 as "THE GREENER FUTURE MACHINES" equipment manufacturer of the year, demonstrating the strengths of Taiwan's machine manufacturers: adaptability, design and integration capabilities. Over 4,000 machines have been introduced in 108 countries over the past 40 years, helping local customers overcome bottlenecks and challenges in production processes in the post-Covid era.

Increasing the recycling rate of plastic packaging as an urgent task in circular economy

The plastic industry is dealing with an increasing problem of marine pollution as the pandemic's use of disposable plastic products rises sharply. According to a recent study published in the journal Science, 1.3 billion tons of plastic waste will be dumped on land and in the oceans by 2040, with plastic accounting for 80% to 85% of today's marine litter, with 50% of it being disposable. In the post-Covid era, the recycling of multi-layer plastic packaging has become a huge hurdle for manufacturers to overcome in the face of increasingly stringent national environmental regulations and trends, resulting in the development of single material composite functional film materials that are 100% recyclable.

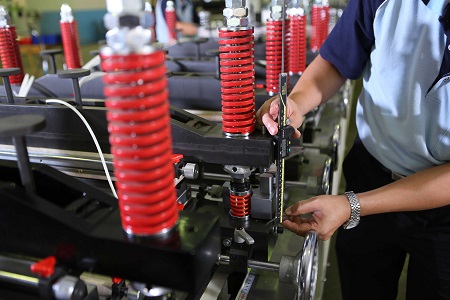

HCI quickly responded and adjusted the mechanism design and control system in collaboration with Plastics Industry Development Center (PIDC) so that the bag-making equipment can be applied to newly developed single-material composite films such as BOPE for a more circular economy bag-making operation.

CE marking, as entry tickets for manufacturers: an EU requirement

The global supply chain is shifting as a result of manufacturing decentralization, and the concept of localized production is resurfacing. Parag Khanna, author of Connectography: Mapping the Future of Global Civilization, has analyzed the new law of the global supply chain: make where you sell. The current pandemic has raised the awareness of multinational companies of the risk of breaking the chain, and the concept of local manufacturing has become a lifeline for multinational companies looking to strengthen the security of their supply chains by relocating factories to Western countries for local production and having to readapt and comply with higher security regulations and policies.

In order to comply with the strict safety regulations of European and American countries, HCI provides a wide range of tight protection upgrades to maintain operational convenience and has successfully implemented advanced industrial safety systems in Europe, providing industrial safety equipment including protective covers, safety switches, safety light curtains, etc. Furthermore, the safety, personnel health, environmental protection, and other related conditions of HCI equipment have been verified by a third-party designated organization to comply with all relevant directives of the European Commission's CE safety regulations, just as HCI manufactures production equipment with EU passports, allowing customers to expand smoothly into the European and American markets.

Adapting to the "new normal" in manufacturing industries in the post-pandemic era

It has been more than three years since the Covid-19 outbreak, while society is gradually moving toward coexistence, the business market is forming a new normal, and the plastic industry is facing numerous new challenges. In the face of a short-term labor shortage, how to improve "automation" has become a hot topic in the manufacturing industry. HCI, with 40 years of experience in manufacturing equipment design, shares its success story of enhancing "automation" to meet new customer needs in the Post-Covid era through systematic innovation and rapid response to customization.