Hexagon AB, a in digital reality solutions combining sensor, software and autonomous technologies, announced a US$100 million investment in Divergent Technologies Inc., a pioneer of green manufacturing technologies with the first modular digital factory for the automotive industry.

Hexagon AB, a in digital reality solutions combining sensor, software and autonomous technologies, announced a US$100 million investment in Divergent Technologies Inc., a pioneer of green manufacturing technologies with the first modular digital factory for the automotive industry.

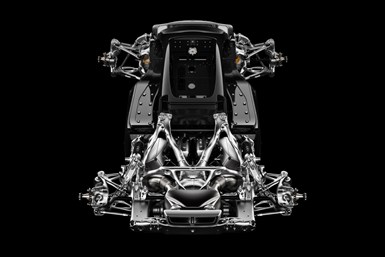

Divergent has developed an alternative production process to traditional vehicle manufacturing called DAPS® (Divergent Adaptive Production System) that addresses economic and environmental challenges head-on. DAPS is a fully integrated software and hardware solution, creating a complete modular digital factory for complex structures. The patented process combines AI-optimised generative design software, additive manufacturing (3D printing) and automated assembly to build lightweight automotive parts and frames.

The design software optimises the weight, strength and cost of vehicle models. Parts are 3D printed and assembled autonomously, reducing manufacturing time and human intervention. Regardless of the design, part manufacturing and assembly can be carried out using the same hardware infrastructure, enabling quick design iterations or seamless switches between different vehicle models without downtime. The design-agnostic process is less energy- and resource-intensive, delivers more efficient structures faster and achieves weight reductions between 20% and 70% leading to dramatic improvements in vehicle efficiency.

"Manufacturing a car's parts has a much greater impact on the environment than the car's exhaust emissions, which is why new manufacturing concepts will win," says Hexagon President and CEO Ola Rollén. "We must find ways to empower car makers with more efficient and environmentally friendly manufacturing processes that minimise material usage and total system cost. Incremental steps are simply not enough to save the planet."

"In my keynote speech at HxGN LIVE Global 2022, I delivered a message of hope for a sustainable future by naming the culprit aloud: all of us," continued Rollén. "While the steep climb in emissions over the last 30 years happened on our watch, none of us want to go down in history as the CO2 Generation – the one that polluted and warmed this planet. For that reason, Hexagon continues to invest in disruptive and unconventional technologies that make giant leaps forward. We are the perfect partner to ensure quality is delivered throughout this new, innovative manufacturing process. Together, Hexagon and Divergent will deliver the smart manufacturing concepts of the 21st Century."

"We are humbled and honoured to be partnering with Hexagon" said Kevin Czinger, Divergent's Founder and CEO. "Having their vote of confidence in what we've built and our vision for the future of manufacturing brings new energy and enthusiasm to our team."

"This significant investment will allow us to accelerate our plans to build a global network of DAPS factories, each serving multiple OEM clients," said Lukas Czinger, Divergent's SVP of Operations and Czinger Vehicles Co-Founder. "We look forward to a long-term relationship with Hexagon as Divergent and Czinger Vehicles scale."

Founded in 2014 and headquartered in Torrance, California, USA, Divergent transforms car manufacturers into agile, design-driven organisations free from capex constraints. A tier-one supplier, its proprietary end-to-end solution is widely applicable to any structure-based, discrete manufacturing process and has already proven to meet the most demanding automotive and aerospace applications.

Protected by more than 500 patents, Divergent's digital, modular, flexible, and automated production solution produces significantly fewer lifecycle emissions than traditional manufacturing. The company not only leads the automotive industry in breaking down capital, geographic, and environmental barriers, but it also has its own portfolio of hypercars, Czinger Vehicles, which produces the fastest production vehicle in the world – the 21C. Learn more about Divergent at www.divergent3d.com.