The five levels of automation: The machine and classic automation come under level 2, and alongside the HMI (Human Machine Interface) on level 3.

Linear and area gantry solutions consist of the same basic assemblies: gantry, set-up station for workpieces, external tool magazine (if required), buffer/lung/warehouse for multiple workpieces (optionally mounted on jigs), gripper changeover station (if required) (gripper for jigs and tools).

Optimal access to the machine

Set-up station

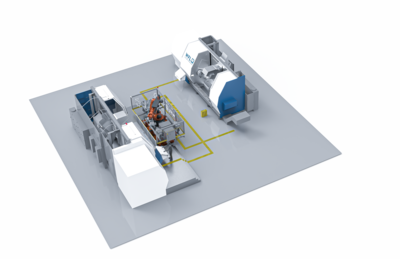

The ever-greater variety of models has meant that transfer lines have tended to be replaced by flexible line chains or by individual cells with a variable material flow. Using intelligent software in combination with the relevant automation solutions not only enables workpieces to be loaded and unloaded but also means that machining centres can be set up fully automatically through the automatic replacement of tools and clamping devices. FRAI strives to be an innovative automation partner and is therefore developing highly flexible robot systems to respond to this trend. These concepts have scope for various expansion stages, making them as future-proof as possible.

FRAI Robotic Technologies provides project support, from initial concept development of an automated system to implementation and commissioning, right through to system maintenance. The range of robotic cells and flexible gantry solutions makes it possible to offer comprehensive automation concepts with maximum customer benefits and to the highest quality standard.

In addition to the classic handling solutions, complex turnkey projects are fitted with a higher-level host computer system. This "brain" takes over the entire logic and logistics from within the fully self-sufficient, flexible production cell. A powerful ProfiNet system allows the machine(s) and robot(s) to communicate with each other. In addition to workpiece tracking and tool management, the system also transmits operational data (operational data acquisition) to the MES system (Manufacturing Execution System, level 4 on the diagram) provided by the customer. In these cases, ETHERNET is used as an additional interface.

One of the most efficient automation variants for production processes is the gantry loader. With loading from above, the modular gantry loader enables unrestricted access to the machine while taking up very little space. Thanks to the fully developed modular systems, long travel paths and large working areas can be realised and huge loads can be handled. The minimal space requirement is often a key advantage in small production areas, particularly when retrofitting automation solutions

Mobile robot automation

Mobile robots move around completely autonomously with no need for any guide cables in the floor, reference positions in the hall or human input for them to work. Another key advantage of mobile robots is that they avoid obstacles, meaning that they can be used in halls where the set-up is constantly changing and where machines and people are moving around. Sensors help to ensure that mobile robots move safely and efficiently between locations and work safely and efficiently with people, forklifts and other material handling equipment.

A major benefit of mobile robots is the access to the machine and the control unit, as the mobile robot is only at the machine briefly to change the workpiece. This guarantees improved accessibility for the introduction of new workpieces or service activities, for example. Thanks to the integrated software and control unit, MRA can be used in mobile situations with absolute confidence. And the integrated laser scanners allow the mobile robot to monitor its surroundings independently and safely navigate around people or obstacles.

Other advantages of MRA:

Manual loading is still possibleAutomatic replacement of jawsMRA can transport and replace both workpieces and toolsIn the case of long runtimes, several machines can be linked together and/or operated togetherIntegration of upstream and downstream processes (cleaning, deburring, surface treatment, etc.)Intralogistics processes can be implementedThe set-up station does not have to be next to the machineThe machines to be loaded do not need to be next to one another.

Using mobile, autonomous robots helps to automate workflows within the warehouse and means that spontaneous errands can also be carried out by the robots. This results in demonstrable improvements in throughput, efficiency and productivity, in both commercial and industrial environments.