Mumbai headquartered Jagmohan PLA-Mach Pvt Ltd emerged as the only Indian company that has designed and introduced injection blow moulding machine (IBM) for the domestic and international market. In the IBM process, the polymer is injection moulded onto a core pin, there the core pin is rotated to a blow moulding station to be inflated and cooled.

The IBM introduced is in European type and available in four models JIBM 40, JIBM 60, JIBM 80 and JIMB 100 with injection mould clamping force of 40, 60, 80 and 100 tonnes and blow moulding clamping force of 6, 10, 12 and 15. While in Beam type, three models launched are JIBM 30, JIBM 50 and JIBM 60 in injection mould clamping force of 35, 50 and 60 tonnes and blow moulding tonnage of 6, 10 and 10, respectively.

The IBM models were developed in technical collaboration with a company based in China. The machine is made in India and branded under the Jagmohan brand with all spares and services offered by the company.

Applications and advantages

The model launched in European and Beam types are for different applications. The European type is used for the production of hollow glass and plastic objects in large quantities. While the Beam type is suitable for PE, PP, PS, PET, COC, EVA etc, material, bottle volume from 1ml – 1000ml. The model range has application in manufacturing packaging bottles for the pharmaceutical, food, cosmetic, chemical and other industries.

In the European range, down-setting of the clamping cylinder ensures clean product. Decreasing the machine height ensures the easy operation of setting moulds. Particular hydraulic servo system and reasonable layout of the pipeline keep the machine operations highly efficient. Particular pressure clamping structure increases the clamping force and reduces the energy consumption. Servo rotation system or high precision indexing device highly increases the rotation precision and reduces the dry cycle time. Optimised internal rack layout keeps the maintenance more convenient.

In the Beam type, clamping part adopts the double-column single beam, the motor space is larger and the replacement mould is more convenient. Injection moulding compound mould adopts the structure of the three gang and small cylinder, make the opening mould faster bring more uniformity. The machine uses the energy saving electro-hydraulic servo system. By using servo slewing system, the turret slewing is fast and smooth.

Composition of European Type IBM

The machine is composed of injection section, injection clamping moulding section, blow plastic clamping moulding section, rotary lifting section, stripping section, hydraulic control section, electric control section, blow control section and others. It could be further customised by adding air compressor and two mould temperature controllers.

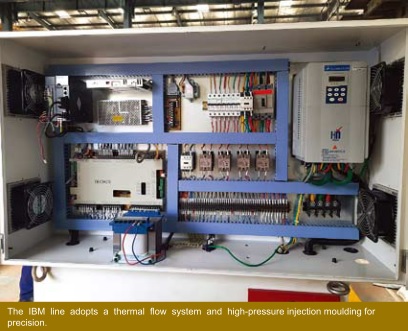

The IBM line adopts a thermal flow system and high-pressure injection moulding to get high precision of bottle mouth, bottleneck and screw. The product has no seam and leftover bits and pieces saving raw material. The products have the same specification and their appearance is beautiful and smooth.

The injection section adopts single-screw stem horizontal injection method. The clamping moulding section adopts horizontal three-work positions rotary device. It can operate in one-mould multiple-chamber continuous production and has high efficiency levels. The high voltage locking mould adopts energy storing device, improve production efficiency and saves energy consumption. It adopts auto stripping and auto flame treating and auto counting, all three sections are combined together to ensure the products are not polluted to meet the stringent demands of food and pharmacy sectors. Adjust rings can be fixed in mechanical, hydraulic, air-control, electric and others to ensure the technological demands of different products. It has strong applicability to raw materials, it can use most thermoplastic materials.

High production efficiency system

The machine has low-mould protection, proportion pressure, proportion flowing adjustment and other functions. It adopts advanced reliable hydraulic and electric components. It has hand-operated, semi-auto and auto operation. The power-saving, high production efficiency machine offers safe and convenient operation and is regarded as an ideal equipment to produce packaging bottles for pharmacy, food and other sectors.

Injection blow hollow moulding machine is composed of frame, injection device, clamping moulding device, injection blow rotary device, stripping device, hydraulic system, gas circuit system, electric control system and others. The frame is welded with shaped steel, front side of the frame has some rigidity to ensure that it does not deform and ensure product quality. On it, the injection and the blow plastics clamping moulding devices; the injection blow rotary device, the stripping device and the gas circuit are fixed.

While on the back side of the frame, jet plastics device is fixed. The oil tank is fixed on the low of the frame. Above the oil tank, there is air filter, an oil exhausting hole (for washing the oil tank) in the low of the back side. The rear end of the frame, P/Q valve plate, motor, oil pump is fixed. In side space there is oil pipeline. The electric control cabinet is fixed in the front internal space of the frame.

The jet plastic device of the machine adopts double-cylinder jetting plastic structure. The jetting force is strong and even. It adopts low-speed large-twisting force hydraulic motor to drive the screw stem. The jetting plastic device is composed of cylinder, screw stem, hopper, jetting plastics, limit controller, screw stem rotary device, mobile cylinder of jet orifice and others. The specially designed screw stem makes plastics evenly melt into melted condition and jet the measured plastics into mould chamber at chosen pressure and speed through thermal current channel. It can get needed pressure and speed through proportion pressure and flow adjustment to be suitable to the demands of different resin kinds and different products.

The injection device has rotary device for convenience in loading and unloading of screw stem and washing charging barrel. The cylinder and the screw stem of the device both adopt high-quality nitrated steel. The non-return ring is fixed in the end of the screw stem to reduce the material flowing back along the screw stem.

The blow clamping moulding device belongs to hydraulic straight-pressing structure. It is composed of guide pillar, moving form board, supporting plate, lock-mould cylinder and others. In order to improve productivity and reduce shocking, moving mould speed adopts slow-fast-slow program. In order to meet the demand of large lock die force of injection plastics mould, on the upper of the injection clamping moulding cylinder there is a booster. After the two parts of the die are tightened, the limit switch sends a signal, the directional valve exchange it, the oil pump supplies oil to the upper chamber of the booster to make the piston of booster move down to increase pressure to reach the demand of high-pressure lock mould.

When injecting and blowing, the circuit of the energy storing device is jointed at the same time, supplement the leak of the oil circuit to ensure the pressure for locking mould. The clamping mould device has low-pressure die protection function. When the two parts of die have not tightened, the lock mould cylinder will not enter the increasing-pressure and locking mould condition. If there is hard material in die chamber at this time, the die will not close tightly. The electric control system will send alarm to make operators remove the trouble.

The injection blow rotary device is mainly composed of dividing mechanism of lifting cylinder, servo motor, turret, fork, roller, core axle and others. The mould core bar is installed horizontally into a straight line on the three sides of the turret at 60. The turret drives the core bar to lift---rotate at 120--- fall in turn, combining the injection, the blow and the stripping three technological processes together. The lifting of the turret is finished by the lifting cylinder. The turret turning 120° is carried out by servo motor; the action exchanging is controlled by the limit switch. The dividing position of the turret is first set primarily by servo motor, then the location pin fixes the precise position.

The actions of the machine - such as injecting, blowing, opening and champing mould, preplasticizing, anti-leak, advancing and backing of the stand, lifting of the turret, resetting, rotating, rotating reset and others - are all controlled and driven by the hydraulic system. All of electromagnetic valves are controlled by 24V DC.

The clamping moulding circuit adopts three single-direction throttle valve to adjust the speed to make injecting, blowing two matching moulding cylinders carry out two-direction synchronization. It adopts differential circuit, boosting circuit and storage-energy circuit to reach saving energy result.

Electric control system is composed of control cabinet, operation casing and electric control device of conveying belt (be ordered separately) and others. The 3-phase 4-wire 380V power is transported to the control cabinet, mould temperature controller and control casing of conveying belt. The control cabinet is composed of injection temperature control device, work circle of the whole machine and control device.

The injection temperature control device is composed of front, middle and rear sections heating of charging barrel, jet orifice heating and thermal flow channel heating. The front, middle and rear sections heating and thermal flow channel heating adopt four temperature controllers control separately the four contactors. The contactors control heating ring of changing barrel to ensure the need temperature of the charging barrel. The jet orifice adopts a thermostat to keep its need temperature.

The machine has hand-operated, semi-auto and full-auto three operation methods. The hand operated function is finished separately with operation buttons and control buttons.