Solutions that enable companies, including start-up businesses, to automate their packing lines to achieve increased production throughput and efficiencies, and enhanced product quality and consistency, will be showcased on the Ishida RSA stand 6 B 32 at Propak Africa in Johannesburg Expo Centre, from 8 – 11 March 2022.

The company will demonstrate models from its multihead weigher, snacks packaging and quality control ranges, all of which combine value-for-money positioning with a number of advanced features to maximise machine performance.

On show at Propak Africa, the Ishida iTPS™ (Integrated Total Packaging Solutions) provides the fastest and most accurate snack food packing system. The space-saving design features an advanced Ishida multihead weigher and bagmaker capable of packing speeds of up to 200 bags per minute on extruded snacks while achieving maximum packing line efficiency and minimum product and film waste. In addition, the proven iTPS™ software facilitates full integration with other Ishida weighing and inspection systems, such as seal testers and checkweighers, to offer a high-speed solution for leak detection, fill level monitoring and pack weight control.

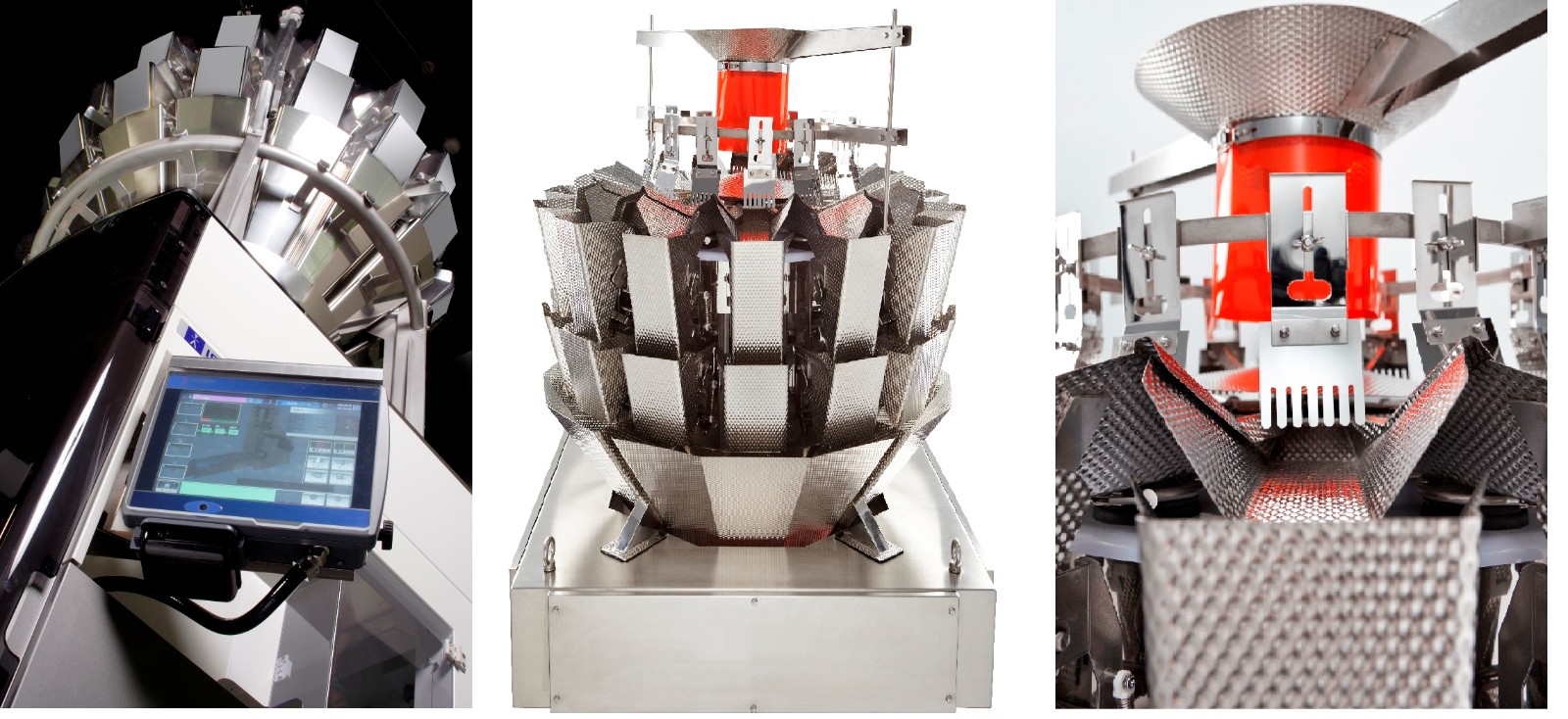

Ishida’s world-leading weighing solutions will be represented on the stand by the CHW-214 multihead weigher. This entry level option is ideal for growing food businesses who are looking to expand their capacity and harness automation, and its excellent value ensures a fast return on investment, typically achieving payback within one year. The weigher can handle dry, free flowing products such as snacks, cereals, biscuits, confectionery and pasta, at speeds of up to 90 packs per minute.

Underlining Ishida’s ability to devise solutions for more challenging and specialist products, also on display will be the company’s Cut-Gate weigher for granular products such as sugar and powdered milks. This incorporates a servomotor-powered gate that delivers a gentle but precise opening and closing profile to offer accuracy levels typically to within 4g for 1kg target weights, and the gentle handling operation preserves particle size and structure. A dust enclosure minimises dust emissions.

The Ishida IX-EN-4093-S X-ray inspection system offers manufactures an affordable but highly accurate entry-level solution, delivering unrivalled foreign body detection and quality control. This provides the highest levels of food safety and product quality to ensure that brand reputation is effectively maintained and protected. The machine can spot a large variety of contaminants such as aluminium, tin, glass, stone, hard rubber, dense plastic, Teflon, PVC, bones and shells at high inspection speeds, and as well as foreign bodies, the IX-EN-4093-S can also identify damaged and missing products or components. In addition, Ishida’s Genetic Algorithm (GA) technology enables operators to optimise the X-ray system for greater sensitivity to specific foreign bodies.

Ishida has also extended its range of ancillary equipment for its X-ray inspection products to offer a solution for bulk products alongside its existing solutions for primary packs.

Additionally, to enhance support for regional customers, Ishida’s dedicated office in South Africa has recently relocated to new larger premises in Kempton Park. This new office features a large demonstration area that enables customers to carry out trials on their products prior to purchase, and comprehensive after-sales support includes a large spares stockholding and local service engineers to ensure a fast response to customer requests.