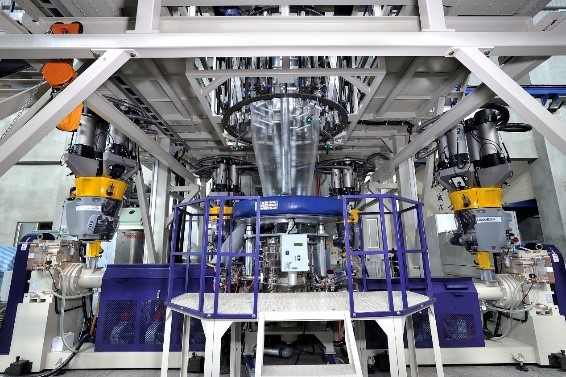

Kung Hsing’s whole plant solutions address major trends in the blown film extrusion sector

With 50 years of experience in plastic extrusion machinery and offers a wide range of blown film lines, monofilament making machine, recycling systems, etc., located in Taiwan, Kung Hsing offers complete 3-layer to 7-layer systems that are ideal for the processing of virgin material as well as recycled and biodegradable materials into plastic films. Various applications such as food packaging, agricultural film, heat shrinkable film, and lamination film, etc. to meet the requirements of worldwide customers.

Mr. Kun-Lin Tsai, Vice President of Kung Hsing Machinery Co., Ltd. shares how the company can raise the efficiency and productivity for the customers through its innovative technology.

What current trends in plastic films production affect the development of Kung Hsing blown film solutions and why?

Mr. Kun-Lin: We see the packaging market for food and beverage changing along with other special markets. That is why more companies require machines that produce film capable of consolidating oxygen and moisture barriers through a high safety standard to prolong the freshness of food. For example, packaging that is appropriate for storing frozen meat down to -40°C, seafood, and dairy products. We also see greater exchange of fresh meat and seafood around the world, thanks to the export agreements for meat products, leading to high demands for safer packaging.

Kung Hsing has been monitoring all these important trends. In response, we have developed and introduced co-extrusion blown film lines that are specifically designed to address the market preference for high productivity and recyclability at the most cost-efficient manner.

How can Kung Hsing blown film solutions realise higher productivity and greater efficiency?

Mr. Kun-Lin: Through the unique machine design, automation devices, and production monitoring system, Kung Hsing blown film solutions help customers to achieve 30% increase in production as compared to other extruders available in the market. Kung Hsing managed to provide advanced blow film system to increase production capacity while keeping energy consumption at the same level. In addition to energy efficiency, performance in terms of speed is the best characteristic of Kung Hsing’s multilayer film co-extrusion machines.

Kung Hsing offers multilayer machines that can be left unattended with automation devices; while production monitoring system is capable of problem evaluations and production data utilization, so to achieve great precision, enhance efficiency, and increase production throughput rate at the same time. For instance, our 5-layer die design reduces melt resident time, enables quick change-over and consistent melt distribution, as well as high output rate. This design is capable of a throughput of 600 kg/h with Ø 300 mm die, and guarantees rate of return that is 2 times the diameter of the die.

Can Kung Hsing blow film line adhere to circular economy targets given the growing market preference for technologies that can process recycled materials?

Mr. Kun-Lin: We are proud to say that our innovative spirit and commitment to excellence have enabled us to respond to the call towards circular economy in plastics production as Kung Hsing has been providing production lines that can process biodegradable materials.

The 5-layer Kung Hsing co-extrusion line is by far our response towards circularity in plastics production. Using multi-layer co-extrusion film blowing machines allows for more flexible material formulations and even higher percentages of recycled materials to be added, which can benefit the recycling economy.

To meet the high demand for food and beverage packaging, the 5-layer co-extrusion blown film line is capable of processing recyclable all-PE multilayer structure film, gaining more relevance in an industry that is fast moving towards a circular economy. This characteristic is built based on the increasing awareness in the application of environmentally-friendly materials. In this regard Kung Hsing has been keeping the balance between improving recyclable all-PE multilayer structure film and reducing the price of this innovative technology.

Automation plays an important role in today’s production operations. Does Kung Hsing offer this technology?

Mr. Kun-Lin: Kung Hsing offers multilayer machines with high production rate - thanks to the outstanding design, which contributes to lower processing cost and increases production throughput rate for customers.

For years, we have been dedicated to improving extrusion equipment, thus as compared to our other extruders, the result was a 30% increase in production.

Within the perspective of maximising production capacity as aligned to the demanding packaging sector, Kung Hsing offers automation system multilayer machines that require less personnel to operate and enable high precision, enhanced efficiency, and increased production throughput rate at the same time.

Kung Hsing Plastics Machinery Co., LTD.

Tel: +886-5 237 4466

Fax: +886-5 237 6971

E-mail: ks.sales@kunghsing.com.tw

Website: www.kunghsing.com.tw