When it comes to sustainability, LAPP and BASF are working together. Both companies want their products to help reduce the carbon footprint. An important component is the use of bio-based plastics. LAPP will now be presenting the first Ethernet cable with a bio-based sheathing in Hall 11, C05 at the Hannover Messe. The compound was developed by the chemical company BASF.

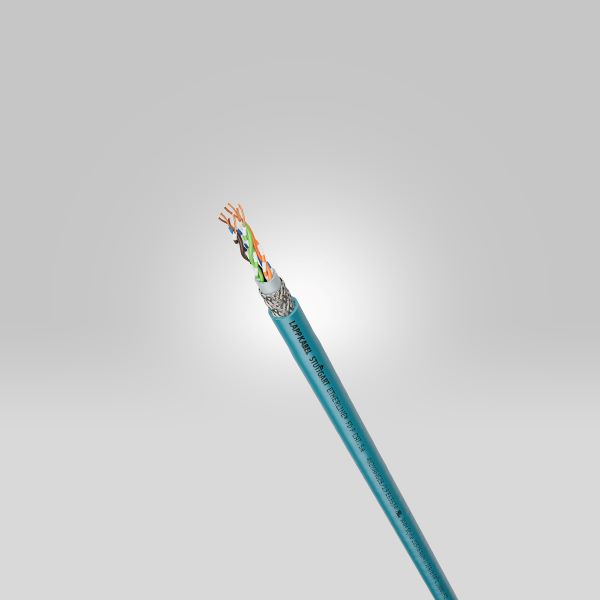

The ETHERLINE® FD P Cat.5e for Industrial Ethernet has in fact been part of the LAPP portfolio for a long time now. It is ideal for patch cable applications and also for cable chains. Now, however, it is additionally available as a more sustainable variant. For this cable, the global market leader for integrated solutions in the field of cable and connection technology has replaced the TPU sheath material (thermoplastic polyurethane) from BASF - previously based on fossil raw materials - with a TPU from BASF that is based on renewable raw materials. “Using plastics from rapidly renewable raw materials with an organic basis is a great way for us to reduce the need for plastics from fossil raw materials and at the same time reduce the carbon footprint of our products,” says Alexander Terpe, Head of Cable Product Development at U.I. Lapp GmbH.

Sustainability begins with more sustainable products

The bio-based plastic in question is Elastollan® N, the thermoplastic polyurethane from BASF. It is a corn-based biopolymer. Depending on the type of TPU, the proportion of renewable raw material is 45 to 60%. The highlight, the TPU offers the same durability, flexibility and mechanical properties as well as the hydrolysis, chemical and UV resistance as conventional Elastollan®. Even the processability parameters are retained. A special feature is that the proportion of biomaterial in the finished product can actually not only be detected, but precisely measured (according to ASTM D 6866).

"BASF's bio-based TPU is a true high performer and is in no way inferior to conventional fossil fuel. A quick changeover in production is possible and the right step to bring our customer real added value through a more sustainable product," explains Oliver Mühren, Group Manager Sales at BASF Polyurethanes GmbH.

Looking at the life cycle assessment, the bio-based product achieves an improvement in CO2 footprint of approximately 15%. And so, it is the logical consequence that the Elastollan® N is part of BASF's circular economy strategy and contributes to saving fossil resources and CO2 emissions. LAPP is also aiming, step by step, to further expand its portfolio of bio-based sheath materials.