High-tech company TRUMPF will be showcasing a new variant of its TruMicro Series 7000 short-pulse lasers at LASYS, the international trade fair for laser material processing in Stuttgart. The TruMicro 7060 and TruMicro 7070 are now available in “Large” versions that offer now four instead of two beam outputs at the same power level. Featuring an impressive 100 mJ maximum pulse energy and 2 kW average power for up to four output ports, these new variants can distribute the laser power across all four ports simultaneously or transmit all of it through a single port. The previous versions of these systems were limited to 850 W.

High-tech company TRUMPF will be showcasing a new variant of its TruMicro Series 7000 short-pulse lasers at LASYS, the international trade fair for laser material processing in Stuttgart. The TruMicro 7060 and TruMicro 7070 are now available in “Large” versions that offer now four instead of two beam outputs at the same power level. Featuring an impressive 100 mJ maximum pulse energy and 2 kW average power for up to four output ports, these new variants can distribute the laser power across all four ports simultaneously or transmit all of it through a single port. The previous versions of these systems were limited to 850 W.

Improved production time

By dividing the beam between multiple output ports, users can take advantage of energy-sharing or time-sharing modes. These different operating modes help users make the most of their laser while also reducing production times. The laser can even be used to carry out simultaneous processing on two different workstations in parallel. “Our TruMicro Series 7000 lasers are a particularly economical option because they enable users to utilize their laser more efficiently, potentially avoiding the need to purchase another laser,” says Steffen Rübling, the TRUMPF product manager responsible for the TruMicro range. In energy-sharing mode, the laser splits the energy up to four different beams at the same time.

"This distribution enables the user to apply the laser energy to different parts of the same workpiece. That can be extremely useful if you are cleaning a large surface, for example, or if you want to process or clean different sides of the same component," says Rübling. Time-sharing mode allows users to deliver the full laser power to one of the four outputs at a time. The new systems are available in different configurations, such as providing three beam outputs with 33 percent of the laser power each, or using time-sharing to provide each output in turn with 100 percent of the output power.

Short-pulse laser systems boost e-mobility

E-mobility applications are just one of the many areas in which TruMicro Series 7000 lasers excel. Welding hairpins for electric motors is a particularly challenging task. Before electric-motor manufacturers can weld the delicate copper pins, they first need to remove the plastic coating. This is where the technology behind the TruMicro Series 7000 comes in particularly useful. The short-pulse laser strips the coating from all four sides of the copper pins, splitting the laser energy to process two sides at a time. Because of the sensitivity of copper, this decoating process only works with the precise energy input of short-pulse lasers. They make it possible to remove the coating layer from the hairpin without harming the copper itself.

TruMicro Series 7000 works using nanosecond pulses

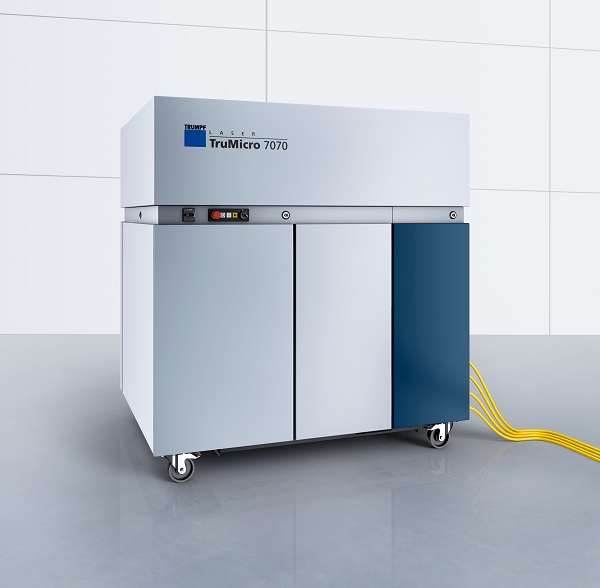

All of the TruMicro Series 7000 variants rely on an infrared short-pulse laser with 30 nanosecond pulse duration. The current series consists of the TruMicro 7060 1 kW laser and the TruMicro 7070 2 kW laser.

Based on disk-laser technology, these high-power nanosecond lasers combine short pulses and high pulse energies – even at high frequencies. Users can modify the laser’s repetition rate while keeping the pulse duration constant in order to optimize the laser parameters for specific applications or materials. By using scanners, the short-pulse lasers can ablate large surface areas with outstanding efficiency. The beam can be delivered using a flexible laser light cable or other suitable beam-guiding components. This makes it easier to integrate the laser in production.