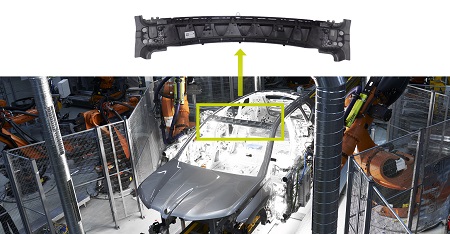

High-tech carbon fibre compounds from WIPAG are used in the Bavarian car manufacturer's new BMW iX: thanks to WIC PA6 15 BK IM, the windshield of the fully electric vehicle features a low component weight and a plus in sustainability. The metal-plastic hybrid component in skeleton design is manufactured by injection moulding.

The WIC compound contains recycled carbon fibres from the production of carbon fibre reinforced plastics (CFRP) at BMW - a good example of circular economy. WIPAG and BMW have a long-standing cooperation in carbon fibre reinforced thermoplastics (CFRTP).

WIC PA6 15 BK IM offers high lightweight potential, very good mechanical properties and is also impact modified. The use of recycled carbon fibres in the WIC compound also ensures a lower carbon footprint compared with virgin carbon fibre: for example, the production of 1 kg of WIC PA6 releases around 6 kg of CO2 eq. compared with around 9 kg of CO2 eq. in the production of 1 kg of virgin carbon fibre. This CO2 balance was calculated with GaBi software.