The original Cone Valve inventor and renowned for their innovative Intermediate Bulk Container (IBC) Systems, Matcon have launched a new product to their range – the Manual Cone Valve (MCV). Designed specifically to help customers in the Food, Beverage and Chemical sectors overcome the problems of mix segregation that are commonly associated with butterfly valve IBCs.

The manually operated Cone Valve promotes mass-flow discharge of free-flowing powders, preventing segregation of powder mixes and ensuring product quality. It is tested and proven as an effective butterfly valve alternative, overcoming the issues of core flow and particle rolling that can be experienced with standard butterfly valves.

The Manual Cone Valve can be easily retrofitted to any existing flanged IBC outlet, providing a cost-effective way of delivering superior powder handling capabilities to an entire IBC fleet.

Matcon Manual Cone Valve Technology – how it works

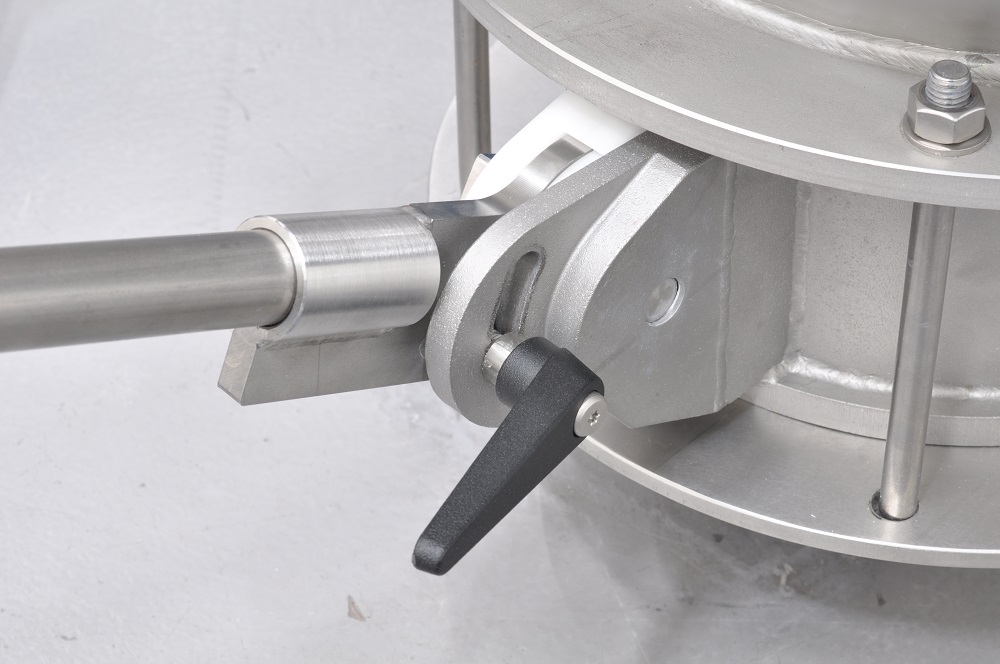

The Manual Cone Valve is positioned in the IBC outlet, where the cone is lifted by pushing on a lever handle. As the Cone Valve rises inside the IBC, an annular gap is created, enabling powders to exit under mass-flow. As the powdered material moves simultaneously, there’s no particle rolling and hence no mix segregation. Bridging and rat-holing, which are common problems with butterfly valve IBCs, are also eliminated.

The operator can lock the lever in the open (100mm height) or closed position with a locking handle, or at any intermediate position in between, depending on the desired product discharge flow rate.

Each unit has a nominal internal diameter of 250mm and is designed to fit a vessel or process with the same outlet size for discharging free-flowing bulk material.

A typical example of discharge time achieved when discharging 1,000Kg of salt from a 1,000-litre IBC is only 90 seconds.

Key features include:

- Simple hand operation

- 100mm stroking Cone Valve

- Variable stroke position locking

- Fast assembly / disassembly

- Promotes mass flow powder discharge

- Prevents segregation of free-flowing powder mix

In applications involving sticky, cohesive powders or where automation is required, we recommend using the Classic Matcon IBC System https://www.matconibc.com/products/ibc.