Mercedes-Benz will build ultra-high-performance axial-flux electric motors at its Berlin site, as the world’s pre-eminent luxury car brand prepares to go all electric by 2030, where market conditions allow. With the transformation of the Berlin site, Mercedes-Benz will reach new digitalisation and electrification milestones on the way towards a sustainable and emissions-free future.

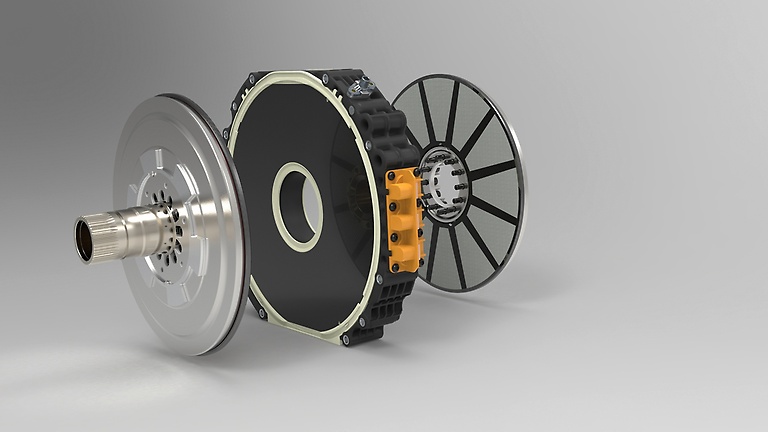

By insourcing further electric drive components, the Berlin plant is charting a new course for its future and expanding its portfolio of products. Mercedes-Benz announced the acquisition of YASA, UK-based manufacturer of ultra-high-performance electric motors in the summer of this year, securing access to unique axial-flux technology, deepening its vertical integration and value creation in development and production. The portfolio of the Berlin plant already includes assembly volumes of electric drive units and the so-called EE Compartment.

In addition, the build-up of the Mercedes-Benz Digital Factory Campus - a campus for the development, testing and implementation of pioneering MO360 software applications – has reached an advanced stage. A series of state-of-the-art pilot lines will go into operation next year. Berlin will become the competence centre for digitalisation in the global Mercedes-Benz production network and support the worldwide rollout for new releases and apps in the MO360 ecosystem. At the same time, the campus will become a MO360 training and qualification centre with innovative approaches in the area of digital implementation. Mercedes-Benz is investing a low triple-digit million euros amount in the transformation of its Berlin plant within the next six years.

In addition, the build-up of the Mercedes-Benz Digital Factory Campus - a campus for the development, testing and implementation of pioneering MO360 software applications – has reached an advanced stage. A series of state-of-the-art pilot lines will go into operation next year. Berlin will become the competence centre for digitalisation in the global Mercedes-Benz production network and support the worldwide rollout for new releases and apps in the MO360 ecosystem. At the same time, the campus will become a MO360 training and qualification centre with innovative approaches in the area of digital implementation. Mercedes-Benz is investing a low triple-digit million euros amount in the transformation of its Berlin plant within the next six years.

In addition, the build-up of the Mercedes-Benz Digital Factory Campus - a campus for the development, testing and implementation of pioneering MO360 software applications – has reached an advanced stage. A series of state-of-the-art pilot lines will go into operation next year. Berlin will become the competence centre for digitalisation in the global Mercedes-Benz production network and support the worldwide rollout for new releases and apps in the MO360 ecosystem. At the same time, the campus will become a MO360 training and qualification centre with innovative approaches in the area of digital implementation. Mercedes-Benz is investing a low triple-digit million euros amount in the transformation of its Berlin plant within the next six years.