Nihonseiki Co Limited, part of GMC Holdings Group, is a well-established die cast molds manufacturer with a 100-year history designing, manufacturing, and servicing die cast molds for more than 1,000 customers—primarily Japanese and international automakers, and other dedicated die-casting and die manufacturers. Today, GMC Holdings Group is the largest die manufacturer in Japan and enjoys an outstanding reputation worldwide as an industry leader, and one committed to innovation.

A core element of the Nihonseiki’s innovation strategy in recent years has been the introduction and subsequent industrialization of metal additive manufacturing.

"Our additive journey started in 2015 when we were approached by an automaker about manufacturing cores (a component of die tooling assembly) with cooling channels," explains Masato Matsubara, Managing Director at Nihonseiki.

"At first, we started by handling post-processing processes, like machining, polishing, and heat treatment for dies that another company had additively manufactured, using a metal 3D printer. Then, as we gained more experience and expertise, we reached the stage where we could develop our own cooling channel designs. In 2017, in order to move casting in-house, we conducted market research to assess the potential of using metal 3D printers, but at the time there was still little customer demand, so we decided to continue outsourcing the casting process," adds Matsubara.

Masato Matsubara, Managing Director, Nihonseiki (Image credit: Nihonseiki Co., Ltd.)

"Then, there were limited choices among metal materials that could be used in metal 3D printers. Instead of the maraging steel that is usually used, we wanted to try SKD61 (Steel Kogu Dice), which is the most used alloy tool steel in die manufacturing, but this material was hard to get hold off and this is one reason we let the idea go," reflects Matsubara.

SKD61 is tougher and has better thermal conductivity than maraging steel, so using it in designs can enable the production of much thinner tooling components that do not break as easily, and potentially extending service life within the die assembly.

At the beginning of 2021, Nihonseiki received a proposal from Mitsubishi Corporation Technos, GE Additive's authorized sales partner in Japan, for an SKD61-equivalent material that can be used in its metal 3D printers.

After surveying industry and customer demand once again, Nihonseiki decided to purchase two GE Additive's Concept Laser M2 systems, capable of higher precision, more detailed geometries and smooth surface formation.

Throughout 2021, Nihonseiki has created a total support system ranging from metal 3D printing design. fabrication to maintenance. To date, the company has proposed, manufactured, and delivered solutions that improve die interior cooling with cores using maraging steel for many clients, but is now planning a total shift to SKD61-equivalent material.

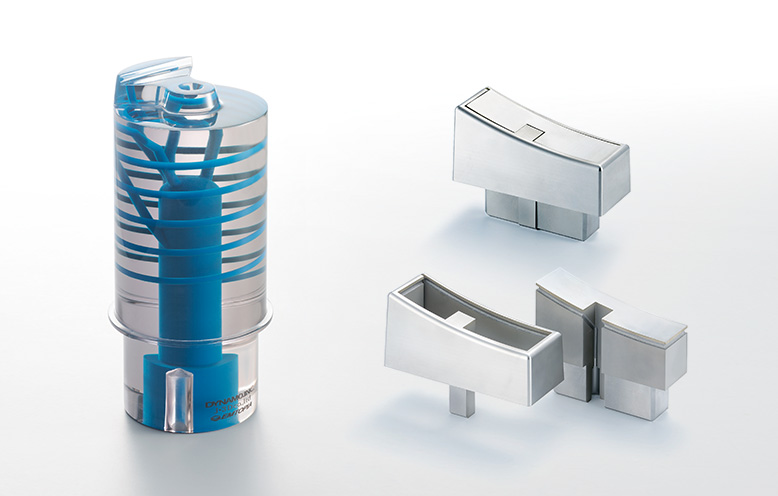

Die cast cavity part manufactured in maraging steel using GE Additive's laser technology (Image credit: Nihonseiki Co., Ltd.)

Acceleration of electric vehicle up take drives adoption of additive in the automotive industry

As the shift to electric vehicles accelerates worldwide, the demand for lighter products that use aluminum parts is expected to grow even more. Said to be a huge, once-in-a-century revolution, this shift is also bringing both new challenges and new business opportunities for Nihonseiki.

Minimizing weight is one of the most pressing problems facing automakers—and for electric vehicles, a lighter vehicle is also essential for increasing the maximum range. To reduce weight, pressed steel components are replaced by cast aluminum parts meaning there is expected to be a greater and faster integration of aluminum die-cast parts and an increase in part and die sizes.

Among the parts being considered for replacement with aluminum, one that is of particular interest to Nihonseiki is the battery case. Battery cases for electric vehicles are becoming lighter and more frequently made of aluminum but they are also becoming larger, posing a greater risk of warpage during casting.

Matsubara is optimistic about the possibilities of metal additive, "Cooling dies internally is the key to reducing warpage in large aluminum parts. We are currently focusing our efforts on internal cooling of dies using metal 3D printing. As we endeavor to improve individual parts and extend their life, we are also trying to find the best way to incorporate internal cooling into the basic die design.

Also, as products themselves become more complex, the difficulty of designing dies for aluminum die casting will rise sharply. As conventional approaches struggle to cope with this increasing complexity in design and manufacturing, I believe that using an approach based on totally new concepts with metal 3D printing will open a path to overcoming these challenges."

Design freedom for cooling channels improves internal cooling performance of aluminum die cast components

The company is using GE Additive's metal additive technology to solve the challenges of designing cooling channels in die insert manufacturing. Nihonseiki can now produce dies which incorporate internal cooling channels in any shape and create these in areas otherwise inaccessible with conventional machining processes.

Increasing die cooling efficiency enables the injected aluminum to cool not just more uniformly, but also more quickly enabling a reduced total cycle time as well as improved quality. This not only boosts production efficiency, but also improves casting quality.

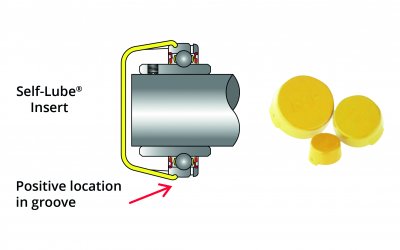

Aluminum die-casting dies are injected with liquid aluminum alloy heated to 660°C. The aluminum is allowed to cool and is then removed. Increasing production efficiency requires reducing the time it takes to cool both the die and the injected aluminum. This is achieved by creating cooling channels inside the die to circulate coolant and speed up the cooling process. Reducing die cooling time means designing cooling channels that can cool the entire die uniformly, yet conventional manufacturing can today still only create straight channels.

Nihonseiki’s cooling channel design for die inserts using metal 3D printing (Image credit: Nihonseiki Co., Ltd.)

How best to incorporate additive manufacturing in overall die design is a critical issue for Nihonseiki. Currently, at die manufacturing plants, the decision about whether a product design can be cast into a product often relies on experience-based judgement.

That being the case, Nihonseiki aims to provide comprehensive support to its customer in areas including coolant flow simulation tools, in combination with the design freedoms of additive manufacturing, enabling visualization of heat transfer throughout the manufacturing cycle, to demonstrate the potential improvement in cooling distribution (quality) and cooling rate (cost) offered by such solutions.

In the future, the company hopes to stand at the forefront of manufacturing using all the technologies accumulated to date, such as casting condition analysis with flow simulation and mechanical property calculation. It is also supporting the development of new manufacturing methods.

Restructuring to combine strengths and specialize in additive manufacturing and R&D to lay the foundation for the die industry's future

Nihonseiki, together with its subsidiary Tooling Innovation, Inc. and Dynamo, Inc., which is a sister company of Nihonseiki, form the GMC Holdings Group.

This group is opening doors in the additive manufacturing business with a framework that combines the strength of each entity—Nihonseiki in charge of die design and manufacturing, technological innovation, and technology proposals; tooling Innovation as an additive manufacturing base; and Dynamo in charge of manufacturing and selling die parts. The group has over 200 machine tools spread among the three companies as well as many outstanding design and CAM engineers. It is opening the door to the future with the motto of 'There is no part we cannot make.'

In August 2021, Nihonseiki established a new company, Tooling Innovation, as a dedicated additive manufacturing and development base. This factory is capable of continual production with metal 3D printing from pre-processing all the way to post-processing. The facility also features a showroom to introduce customers to the Group’s additive manufacturing technologies.

The factory also acts as a laboratory for collaborating with manufacturers that possess similar technologies and for creating new manufacturing methods with related companies, working together to advance additive manufacturing technologies.

GE Additive M2 Series machines installed at Nihonseiki's second plant (Image credit: Nihonseiki Co., Ltd.)

Today, the company has set its sights on transforming the aluminum die casting industry but is developing its business to expand into other fields in the future. Nihonseiki has been meeting its customers' needs for 100 years with completely novel solutions in the die industry. Now through additive manufacturing, it aims to shake up conventional beliefs in the die industry about what a die can be and what die casting can achieve.