The industry needs to see a step change caused by cost pressure, supply chain challenges, lack of skilled workers and steadily increasing legislative and public pressure regarding sustainability. As Ms. Cornelia Beyer, Managing Director of sensXPERT (www.sensxpert.com) puts it: “Here you can think about energy saving, scrap reduction and the optimisation of production processes. Within these overarching industry trends, we see that the general topic of sustainability and the demand to create transparency in production processes based on data are the most pressing.”

The topic of sustainability is manifold and unfortunately, various aspects get mixed up when discussing sustainability and ecologically friendly measures. “The industry needs to look at fast and efficient actions, differentiating between long-lasting and disposable products, especially emphasizing avoiding single-use plastic packaging. Another significant issue is recycling and the clean separation of the materials. The challenge of the plastics industry is dealing with the enormous amount of plastics in the market – around 500 different plastic materials – that cannot be shredded together and recycled easily. At the same time, composites are the predestined material for lightweight production such as automotive parts,” Ms. Beyer explains.

Ms. Cornelia Beyer and Dr. Alexander Chaloupka, Managing Directors at sensXPERT

Once started with the intention to optimise plastics manufacturing processes, sensXPERT solution turned out to be heavily impacting and contributing towards sustainable production, achieving to decrease of up to 50% of existing scrap, 23% in energy savings, 30% cycle time reduction, and 15 days p.a. in downtime and installation reduction. sensXPERT is committed to providing the change for sustainable plastics production that is so desperately needed.

On the other hand, customers seek end-to-end, integrated, and tailored solutions to tackle their challenges around consistent process stability while ensuring cost efficiency. “There are many part-solutions available on the market, however none of them is able to offer full transparency on the manufacturing process in real-time. We realise the full potential of smart manufacturing through the vertical integration of unique state-of-the-art, AI-powered, cloud-based process control tools in combination with NETZSCH Group's renowned material measurement instruments. In addition to creating complete transparency in the manufacturing process of plastic parts, sensXPERT openly welcomes ecosystem partners who understand that stand-alone solutions will not be sufficient to meet tomorrow's customer needs in increasing production challenges. We consider ourselves thought leaders and collaborators, true to the motto: Better together! In the long run, we all benefit from a more profound understanding between machine, process and inline behaviour, which becomes more measurable through collaborations.” according to Dr. Alexander Chaloupka, Managing Director at sensXPERT.

Although there is a strong urgency in the plastics manufacturing industry to get transparency on all facets of the production process, allowing for rapid process optimisation, customers are currently lacking know-how and skills to achieve this, nor have the possibility to easily source this, “We are talking about years of material expertise, process knowledge, collecting thousands of valuable datapoints and the skillset to turn this into immediate added value. For sensXPERT this is a huge opportunity; we offer a solution combining material science and an in-mould material evaluation system that provides real-time answers. The knowhow, complex and sophisticated sensor technology comes with broad domain knowledge and leaves the market looking for its equal,” Dr. Chaloupka stressed.

As a global industry expert, NETZSCH has been active in plastic material science and sensor technology for over 50 years.” Over the last two years, sensXPERT adopted and rethought the technologies we have in place as a Group to help plastics processors and ecosystem stakeholders to achieve unseen holistic process stability, thus allowing dynamic manufacturing. With sensXPERT Digital Mold, NETZSCH is now also digitally serving the plastics industry with an Equipment as a Service (EaaS) product,” according to Dr. Chaloupka. The hardware is leased, and a monthly subscription allows an immediate high return on investments.

Enhancing productivity in real-time

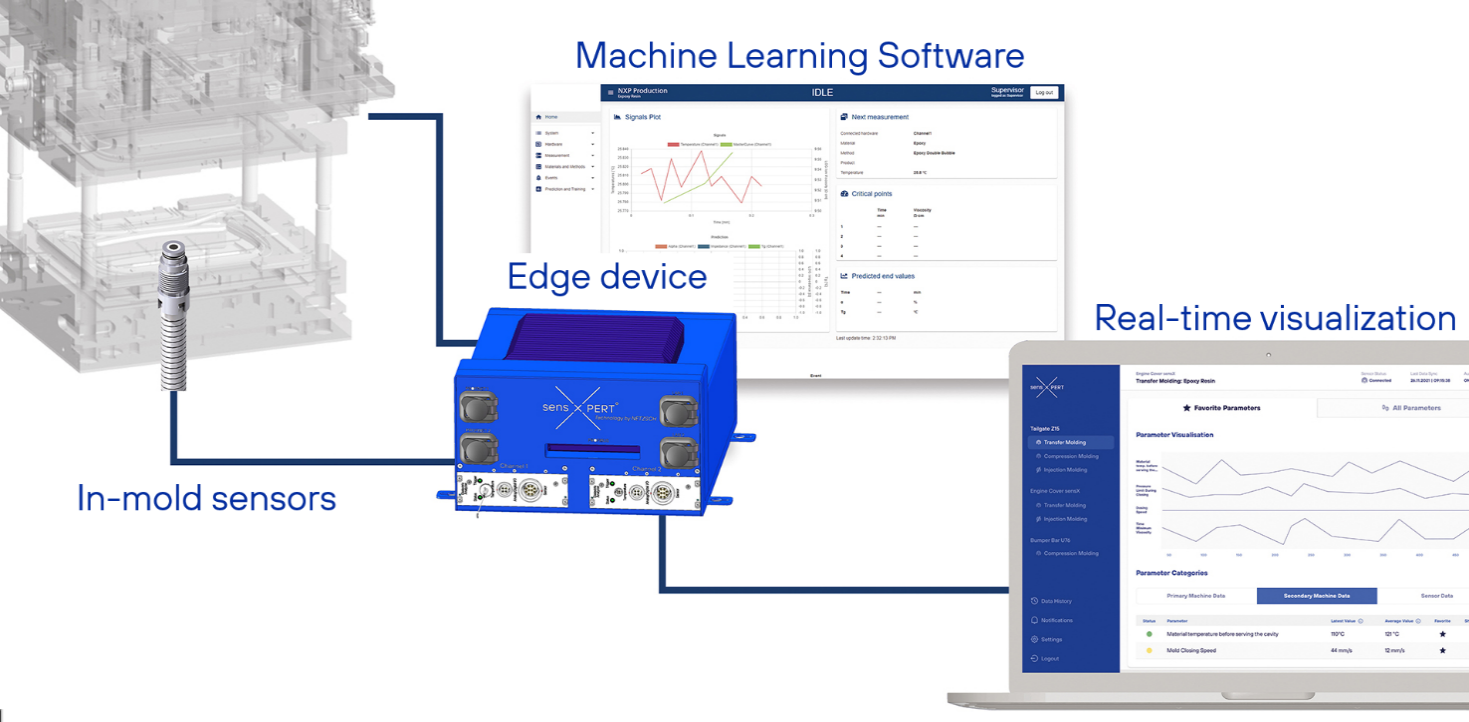

The plastics manufacturing solution is data-driven and enhances productivity in real-time. Sensors measure and stream machine data that allows an AI-based answer to characterise materials dynamically and control all necessary influencing factors to optimise the moulding process.

Dielectric sensors are the heart of the system, favourably positioned at or close to the main gate, while the second one sits best at the end of the flow—regardless of part size. Data collected by the sensors are transferred to the sensXPERT edge device, which is placed machine near. The edge device acts as an industrial PC with the main task of evaluating and communicating the data received to the Cloud via secured servers maintained by Amazon Web Services.

Besides the immense measurement hardware know-how incorporated in its sensors and the edge device, the sensXPERT technology excels in its mathematical and physical/chemical models of material behaviour and machine learning algorithms that constantly scan incoming data for patterns and deviations in the background. The algorithms translate the raw sensor data into predictive quality criteria, feeding them back to technicians, monitoring a given machine and process via a web app.

An additional layer of machine learning algorithms supports the system parsing the process parameters and sensor data flowing in from customer moulds in manufacturing facilities worldwide, displaying the process outputs and operating conditions using data science. Over time, the amount of data created enables predictive analytics to kick in, thus promising unseen process stability. In more depth, algorithms note data set deviations; correspondence starts with the local edge device, which alerts the workers that monitor the process. The machine learning models running in the background experience consistent retraining when patterns change, ensuring the process's performance.

From Europe to the rest of the world

Europe is sensXPERT's entree region. However, it happily onboarded customers from Mexico and Australia and plan to expand officially to North America and Latin America next year. It serves clients from diverse industries, including automotive, aerospace, building & construction, renewable energy, electrical application, military defense, consumer goods and electronics encapsulation.

“As stated above, we target the European Region and will expand to North America and Latin America in 2023. We also plan to further grow our Digital Mold products in the European region where our current focus is,” according to Ms. Beyer. Furthermore sensXPERT supports several manufacturing processes like (Reaction) injection moulding, resin transfer moulding, compression moulding, vacuum infusion, and others.

sensXPERT is also launching a new product based on its current technology, in the field of quality control for trenchless sewer rehabilitation. “Today's sewer rehabilitation market using plastic liners faces significant challenges in controlling the entire curing process and our sensXPERT pipe product offers a sustainable solution, controlling the curing of the liner, increasing efficiency on the job site and controlling quality at every point of the curing process. We are able to monitor the curing of the material along the entire length of the sewer. It measures non-invasively (no dig movement) and therefore has no negative impact on the liner,” Dr. Chaloupka explains.

For more information, visit: www.sensxpert.com

- To read the complete Outlook 2023 Special Report in the International Plastics News for Asia - December issue, click here.