Renewably sourced biomaterials and lower sintering temperature result in a more sustainable substrate for powder bed fusion technologies requiring less energy use and a carbon footprint 89% smaller than PA-12.

NatureWorks, leading manufacturer of polylactic acid (PLA) biopolymers, announces, in collaboration with Jabil Inc., a global manufacturing solutions provider, the availability of an Ingeo™ PLA-based powder formulation for powder-bed fusion technologies, including selective laser sintering (SLS) printer platforms. The new product marketed as Jabil PLA 3110P, offers a cost-effective option, with lower sintering temperature, and 89% smaller carbon footprint compared to the incumbent PA-12. Ingeo PLA is derived entirely from annually renewable resources, meeting demand for a biobased alternative to petrochemical-based powders, like PA-12.

“NatureWorks’ expertise in performance biomaterials and Jabil’s position as a leader in design, product development and manufacturing of highly engineered and qualified materials made our collaboration a natural choice,” said Salvador Ortega, Global Industry Manager, NatureWorks. “The resulting Jabil PLA 3110P powder is suitable for applications where incumbents may be over-engineered, thereby delivering both a lower cost and reduced carbon footprint product, compared to conventional powders.”

Compared to 3D printing methods such as fused filament fabrication (FFF), advantages of SLS include greater output, accuracy, and design freedom. As a result, this Ingeo PLA-based powder can form the custom, precision geometries needed for thermoforming and compression molds. Moreover, the significantly lower sintering temperature of this product translates to energy savings and faster start-up, allaying the relatively high energy usage of SLS-systems.

“Jabil is excited to work with NatureWorks in driving adoption of Jabil PLA 3110P, as well as other highly engineered and qualified materials that deliver value-added attributes while reducing environmental impact,” said Luke Rodgers, senior director of R &D for additive manufacturing at Jabil. “Our ongoing collaboration will enable us to propel the additive manufacturing industry forward with more sustainable material choices for a wide range of customer requirements.”

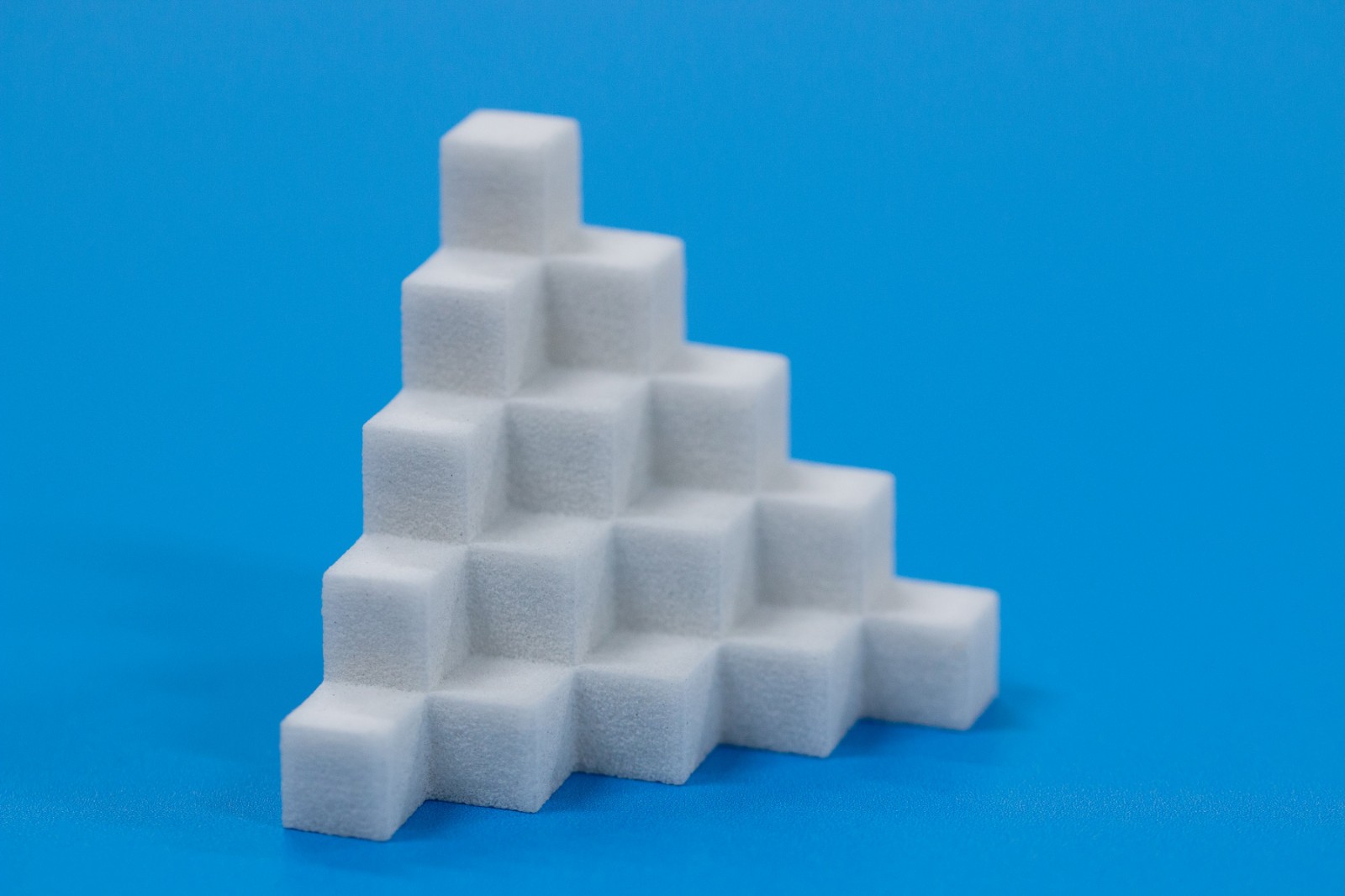

All of NatureWorks’ Ingeo biopolymer materials are derived from plant sugars. Plants naturally capture and sequester atmospheric CO2 in the form of long-chain sugar molecules. Fermentation of those sugars results in production of lactic acid, which NatureWorks uses to produce a range of high-performance materials with a significantly smaller carbon footprint than petrochemical-based polymers.

The Jabil PLA 3110P powder made with Ingeo for SLS 3D printing is now available directly from Jabil through their sampling program. Visit Jabil.com for more details.

Parts printed with this new powder will be on display at RAPID + TCT, May 2-4 in Chicago in the NatureWorks booth (#3056) and the Jabil booth (#2140).