MEAF Machines has added a PROMIX physical foaming installation to its in-house extruder test and demonstration line. Customers are now able to get hands-on experience with this material saving equipment while using their own polymer grades in the process. The potential savings from the PROMIX equipment come in addition to the benefits of the MEAF extruders that are already among the best for energy efficiency and economy.

Physical foaming offers a significant material saving potentials for extrusion processes, according to Roald de Bruijne, Sales Manager at MEAF. PROMIX are setting new standards in the production of microcellular foam products with a very homogeneous cell structure and unprecedented process stability, while using eco-friendly CO2 and N2 blowing agents. Depending on the application, density reductions of 5% to more than 30 % can be achieved. The resulting material saving will not only benefit the plastic processors, but also their customers and the environment.

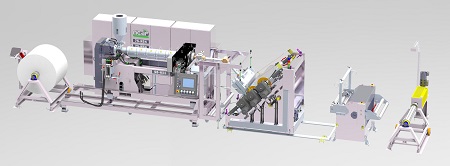

When opting for a new type of raw material, material mixture or a new machine supplier, it is always helpful to be able run a test before deciding the best way forward, Mr. Bruijne explained. With MEAF’s new in-house test and demonstration line, MEAF can provide this capability to customers. MEAF extrusion line has been designed and build to accommodate the latest technologies, such as physical foaming, and a wide variety of materials for customers’ packaging needs, be it PET, PE, GPPS, PS, PP, PLA or biodegradable grades.

For any sheet or film extrusion, the largest contribution to the production costs are by far raw materials, often surpassing 70% of the total production expenses, usually followed by energy consumption. Therefor every manufacturer is looking to reduce its overall production costs by reducing the raw material expenses. One approach is to increase the amount of recycled material, regrind skeletal waste or bottle-flakes in the case of PET film extrusion, or the utilisation of filler components such as CaCO3.

“To reduce the overall raw material costs further, even more needs to be done,” explains Roald. ’This is where MEAF’s sheet extrusion line in combination with PROMIX physical foaming comes in. Not only will it typically reduce the cost of plastic raw material by 20% compared to conventional packaging, the overall weight reduction of 10% to 30% has further benefits, as some countries use this a basis for packaging taxes. In addition packaging can be made 100% recyclable, while also allowing the utilisation of recycled raw material, also foamed.

The micro foam process offers excellent rigidity, insulation and insensitivity to scratch marks, and results in the lowest energy consumption per kg in the industry. With the set up processors can work with multiple types of materials in one extruder, such as PP, PS, PET, PE, GPPS and PLA. Both foamed and non-foamed sheets can be produced on the same line, even allowing for multilayer A/B/A sheet, where the A-layer is a solid non-foamed layer, and the B-layer is of a foamed material.