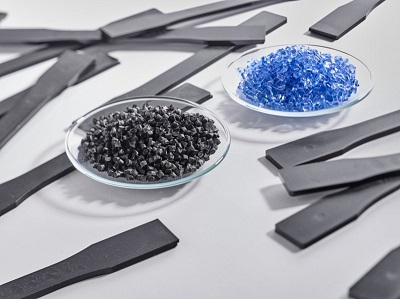

The Maezio® brand of continuous fibre-reinforced polycarbonate composites (CFRTPs) developed by Covestro are characterised by their extremely light weight, very high strength and exceptional flexibility of design. This means that waste generated during the production of composites also becomes a valuable raw material. However, because they consist of different materials that cannot be easily separated from one another, the recycling of composites is a challenge. Covestro is cooperating with recycling specialist carboNXT® on this. It has developed a process that allows the waste to be processed on an industrial scale.

Lisa Ketelsen, Head of Thermoplastic Composites at Covestro, explained that by recycling according to type at the partner's plant, the raw materials can be converted back into valuable products with similarly good properties as those characteristic of virgin materials. “The recycling of materials makes it possible to use them again in other products; this way, we save raw material resources and contribute to the focus on the circular economy,” according to Ms. Ketelsen.

Tim Rademacker, general manager at Mitsubishi Chemical Advanced Materials remarked that Mitsubishi Chemical Advanced Materials has many years of experience in recycling carbon fibre-reinforced thermoplastics and has the necessary plant technologies to process such waste. “We were therefore the partner of choice for this task. From the processed waste, we produce high-quality new compounds of carbon fibre-reinforced polycarbonate for Covestro at CarboNXT®," according to Mr. Rademacker.

Demand for such recycled products is high because they are valuable raw materials, but also because a growing number of industrial customers and consumers are looking for more sustainable products. The project will now be further developed to market maturity by Covestro, Mitsubishi Chemical Advanced Materials and possibly other partners. It is part of a global strategic program with which Covestro is focusing all its energy on the circular economy.