By: Kathryn Gerardino-Elagio

Founded in 2002 in Canada, Creaform was born out of the need to change the status quo. What began as a metrology and engineering consulting firm turned into a global leader in portable and automated dimensional metrology solutions. Now, 20 years later—the company continues to redefine the boundaries of 3D metrology and engineering services by constantly pushing back the limits of innovation.

Founded in 2002 in Canada, Creaform was born out of the need to change the status quo. What began as a metrology and engineering consulting firm turned into a global leader in portable and automated dimensional metrology solutions. Now, 20 years later—the company continues to redefine the boundaries of 3D metrology and engineering services by constantly pushing back the limits of innovation.

International Metalworking News for Asia’s (IMNA) interview with Mr. George Tan, Sales Manager – RoAPAC, delves into Creaform’s secret to achieving 20 years, 3D measurement and where the technology will go from here in South East Asia (SEA).

IMNA: Congratulations on your 20th anniversary! How are things shaping up for Creaform since its establishment in 2002?

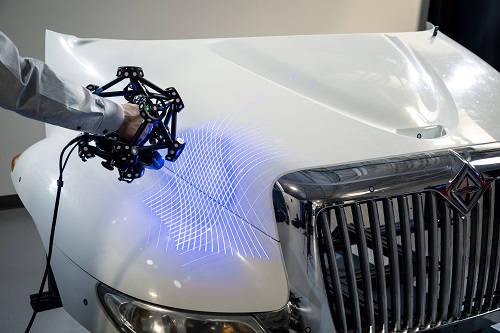

George: Indeed, this year is our 20th anniversary. Creaform first started in 2002 in Lévis, Quebec, Canada, as a metrology and engineering consulting firm, and our first HandySCAN 3D was launched in 2005, which was the first ever handheld self-positioning 3D laser scanner. Since then, Creaform has never stopped innovating. In just 20 years, Creaform had launched over 60 game-changing technologies, both hardware and software. With continuous market adoption, it enabled Creaform to generate substantial and constant double-digit growth almost every year over the past 2 decades!

IMNA: What is the secret to achieving 20 years? What is your top tip for creating innovations such as 3D measurement?

IMNA: What is the secret to achieving 20 years? What is your top tip for creating innovations such as 3D measurement?

George: There is no big secret for achieving 20 years. Creaform always believed in investing in our employees through passion and commitment. Providing our employees with real opportunities to achieve work–life balance and fostering a positive and pleasant workplace atmosphere where everyone feels like they are part of the team. There are no limits to how far we can go, and we are looking forward for many more 20 years to come.

As for the top tip, I would say that at Creaform, we are pioneers. We venture where nobody else has yet dared to tread, boldly designing products and technology for projects that were once beyond the imagination. We redefine the boundaries of the 3D universe by constantly pushing back the limits of technology.

Our motto says it all: “Never Stop Innovating”.

IMNA: Can you brief us about your presence, business model and verticals and sectors you cater to in SEA?

George: Creaform is present in almost all countries in SEA, either through direct offices and/or indirect distributors/agents. We believe that it is important to be present in the countries where our customers reside, in order to provide better support/service.

Regardless whether it is through our direct employees or distributors/agents, there will always be someone representing Creaform to attend to our customers’ enquiries, such as non-destructive testing (NDT), from surface inspection for O&G pipes to maintenance repair and overhaul (MRO), and from reverse engineering applications for prototypes to automated quality control inspection systems for daily production.

IMNA: How do you find out what the customers really want or what is more important, satisfying an existing need or creating new needs?

IMNA: How do you find out what the customers really want or what is more important, satisfying an existing need or creating new needs?

George: It is important for every Creaform employees to understand/discover what the customers’ “Needs” and “Wants”. The “Needs” are something that customers must have, in order to proceed with their jobs and the “Wants” are something good to have but not necessarily required to complete their tasks. Creaform employees participate continuously in technical and sales training to obtain these specific skills.

Although, it is always a tough question to answer. For me, satisfying an existing need and creating new needs are both equally important. But if I must choose between them, I prefer creating new needs, as there are still a lot of uncharted areas where 3D scanning applications can help customers in a way they never thought or dreamed of before. And the satisfaction that you get from these customers when they tell me how much money or time, they saved by implementing 3D scanning into their inspection process, that’s priceless.

IMNA: What makes Creaform achievements stand out? And what does the future hold for 3D measurement in SEA market?

IMNA: What makes Creaform achievements stand out? And what does the future hold for 3D measurement in SEA market?

George: As mentioned, Creaform is the pioneer of handheld 3D scanners. We are a technological leader – not a follower. Creaform was founded because other measurement technology defined as “portable” were simply not suitable for shop-floor environments. We aimed to tackle our customers’ most difficult challenges and are eager to push the limits.

I foresee an increasing demand in the coming years, especially considering the rise of new production processes like 3D printing, where parts are no longer machined in a single, straightforward geometrical shape, and then assembled. It will be “printed” in a single completed part with complex geometrical features, where conventional handheld measuring tools will face difficulties in measuring it.

This is where 3D measurement solutions, especially Creaform handheld 3D scanners, are the perfect go-to inspection tools for faster and more accurate inspection of these complex geometrical surfaces, directly in the production environment, with the help of inspection software features like CAD comparison for quick Go/No-Go colour indicator checks.

IMNA: What’s the toughest project or customer request Creaform has been confronted with? Did it influence the company’s approach on creating new technologies?

IMNA: What’s the toughest project or customer request Creaform has been confronted with? Did it influence the company’s approach on creating new technologies?

George: As mentioned before, Creaform started as a metrology and engineering consulting firm, helping local manufacturers solve their product development and inspection issues. During those early years, we worked on several projects, using our competitors’ tools, which were cumbersome and slow 3D scanners mounted on a CMM. We experienced first-hand the difficulties in using such tools. We knew there was an opportunity to greatly improve these tools, because we listened to our team and our customers. We didn’t need to receive a formal request from our customers to understand the pressing necessity for better tools.

In the following years, we created the next generation of 3D scanners, and disrupted the entire market. We were spearheading a real technological revolution, and even if the interest was immediate from all industries, it remains to this day the toughest project we have been confronted with. From a handful of employees in Levis, to more than 650 employees in 15 offices across the world, Creaform proved that it can tackle any challenges, head-on.

IMNA: Finally, what’s next for Creaform in SEA?

George: We are very excited with the growing business opportunities in SEA, especially in the 3D measurement sector. We believe there are a lot of business potential in this sector in SEA and Creaform, being the pioneer in handheld 3D scanners, wants to be there with our customers, share our latest technologies, helping them to reduce turnaround time and most importantly, to increase their profitability.

IMNA August 2022 issue click here!