High-power diode lasers with outputs of ten or more kilowatts open new application scenarios for laser cladding. Particularly sustainable and resource-efficient coatings can be produced and applied, for example in automotive, machine construction and other industries. Together with industrial partners, the Fraunhofer Institute for Material and Beam Technology IWS has developed applications and specific processes for this laser class to industry readiness under the label “HICLAD®”.

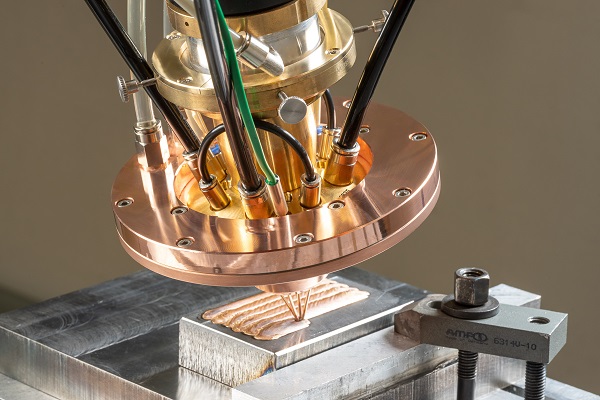

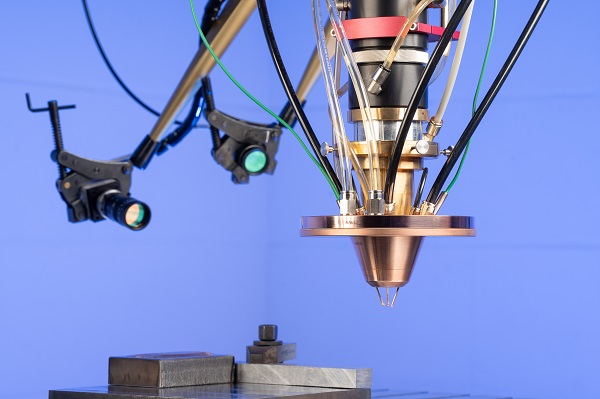

For the first time, simultaneous processing of powder and wire in various combinations becomes possible thanks to COAXquattro. The materials meet in the laser focus above the component surface, where the laser melts the coating metal. Directly on the surface, the coating is created in-situ from the powder and the individually fed wires. © ronaldbonss.com/Fraunhofer IWS

High feed rate, optimal speed, and large spot: Fraunhofer IWS has been developing the HICLAD® process family for laser cladding for several years to enable customised solutions for highly productive coating processes using high power diode lasers. To this end, the researchers are, among other things, fine-tuning the parameters of energy distribution, speed and feeding rate in such a way that wide process windows become possible and fluctuations in the production process become tolerable.

“We are once again pushing the limits of applying high-power lasers,” emphasises Dr. Maria Barbosa, who heads the Thermal Coating Department at Fraunhofer IWS. HICLAD® does not only enable sustainable functional coatings that ultimately improve the durability, wear resistance and lifetime of the components processed with it. The technology also brings resources such as material, time and costs into the best possible balance, she adds.

Maria Barbosa states, “We look at the functionalisation of component surfaces holistically and with the goal of still achieving resilient as well as industry-ready results with minimal material use and short cycle times.”

The researchers say that a key component is measurement and control hardware, some of which has been developed in-house, that enables them to monitor and regulate the complex process and control its quality.

“In this way, we are contributing significantly to greater resource efficiency in industry,” adds Maria Barbosa. HICLAD® comes into play, for example, for the laser-based hardfacing coating of brake discs, hydraulic cylinders and plain bearings. In the future large components for the oil, gas and paper industries and many other sectors may also be coated efficiently.

One core element of the HICLAD® family is the innovative COAXquattro laser cladding head. A laser beam runs through the center of the nozzle, around which up to eight separately controllable channels feed wires and powders. This flexibility also saves material costs, because wires are often only half as expensive as powders. © ronaldbonss.com/Fraunhofer IWS

Application rate tripled with 20 kW laser

Laser cladding has since long been used for high-quality industrial coatings. However, this process only allowed a comparatively low deposition rate at high investment costs. Yet this is crucial for productivity, which is why companies have rarely used it for large components and bulk series. This has changed with the increased availability of industrial diode lasers with ten, in some cases up to 20 or more kilowatts of power, which permit much higher deposition rates. Nevertheless, the use of these high-power lasers requires special process expertise.

For many years, Fraunhofer IWS has been a pioneer in the use of high-power lasers with steadily increasing power classes – especially for laser cladding. Based on this experience, the Dresden institute and the company Laserline have now achieved and surpassed deposition rates with 20-kilowatt diode lasers which were previously only feasible using Plasma Transferred-Arc Processes (PTA). The partners have also made considerable progress compared to existing laser-based solutions: Depending on the specific material and the nozzle selected, HICLAD® achieves deposition rates of 18 kilograms per hour in industrial use. For an Inconel 625 nickel alloy, for example, productivity can be roughly tripled compared to a solution using a conventional nine-kilowatt laser. The exact values depend on the specific application scenario. Compared to competing solutions with high-power lasers, the Fraunhofer IWS process is considered more robust.

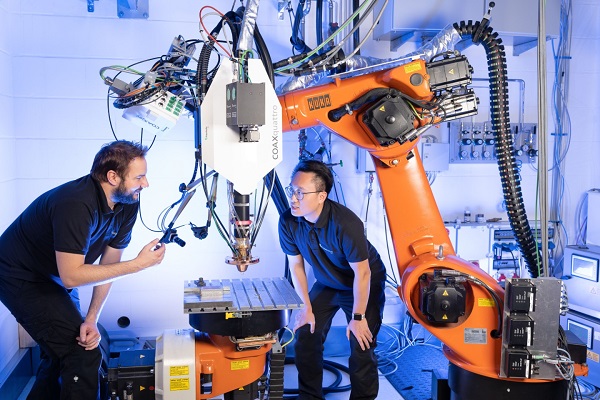

As key component, measurement and regulation hardware developed at Fraunhofer IWS serves to control the quality of the complex processes. © ronaldbonss.com/Fraunhofer IWS

COAXquattro can process powder and wire simultaneously

In contrast to powder-based laser cladding, wire-based processes were previously limited to a maximum of six kilowatts. COAXquattro now enables laser power of up to 20 kilowatts to be used in the combination of wire and powder. This can play a decisive role in multi-material development, for example of novel alloys. Different materials can be fed as required through each of four wire and powder channels. In addition, the comparatively short processing times shrink expenditures for staff, shielding gases and other operating costs. In general, the system is designed for particularly efficient material utilisation as well as very robust and flexible process control with high quality.

Next step leads into 45-kilowatt class

“Together with Fraunhofer IWS, we have succeeded in opening up concrete applications for a new class of high-power lasers to industry,” explains cladding and additive manufacturing expert Dr. Sörn Ocylok from industrial laser manufacturer Laserline in Mülheim-Kärlich.

“Currently, we are already testing the further scalability of the processes by using a higher diode laser power class with up to 45 kilowatts output power in test runs – aiming at potential industrial application in the near future.”

The project partners presented their joint work at the LASER World of PHOTONICS trade fair in April 2022. There, Fraunhofer IWS informed about HICLAD®, presented the laser nozzle COAXquattro and show a high-power laser welded plain bearing. In addition to a 45-kilowatt diode laser, Laserline also presented brake discs coated by high-power laser cladding. Thanks to high-quality laser coating, they release less abrasion and may thus help to reduce fine dust pollution in city air.

Source: Fraunhofer IWS