The FFM machine uses the backward flow-forming process to form weight-optimised rim rings

Less weight means fewer CO2 emissions - this applies to both cars and trucks. There is a lot of saving potential in wheel rims. With Leifeld Metal Spinning GmbH’s flow-forming machines, the chipless production of weight-optimised wheels will be possible - without loss of payload.

“With our machines and technology, we can design steel rims for cars and trucks so that they’re significantly lighter than conventional wheels and yet just as strong,” explains Benedikt Nillies. He is the Technical Director of Leifeld Metal Spinning GmbH in Ahlen in Germany. The company develops machine tools for chipless metal forming, which are used worldwide in the automotive industry, aerospace technology, the energy industry and in various consumer and industrial goods sectors. "One of our customers was able to use our technology to produce rims with a payload of 580 kilograms, which is almost 900 grams lighter than with other manufacturing processes,” he says. This pays off, especially in terms of fuel consumption. And the more wheels are used, the better the result. Benedikt Nillies is thinking here of a tractor unit with six wheels, plus spare wheels, and trailer wheels.

So why don't the manufacturers go straight for aluminium wheel rims? After all, they are much prettier than their steel alternatives and are very popular with car buyers when they have been painted, mirror-finished, matt brushed and sometimes chrome-plated. But they are also more expensive - and more vulnerable, e.g., to road salt or impacts. Repair is costly and/or sometimes impossible. “Steel rims are much more resilient, and with the right manufacturing process they can actually be even lighter in the car sector,” Nillies describes. This is different than the truck sector. But here, too, the weight savings can be attractive to truck manufacturers and buyers who are less concerned with design and more with economy.

Benedikt Nillies, Technical Director at Leifeld: "Manufacturers can use our machines to design the wheels as they are required by vehicle producers - light with a high payload."

Less weight and still more resilient

If aluminium rims are often cast or forged in one piece, steel rims usually consist of a rim ring and a wheel disk. The rim ring can be produced in the car sector, and both parts can be produced in the truck sector using the flow-forming process. Work hardening improves the microstructure in the material and thus increases the final strength. “We have the possibility of reducing the material cross section at certain points and flexibly adjusting it to the load requirements of the wheels,” says Nillies.

Weight-optimised rim rings

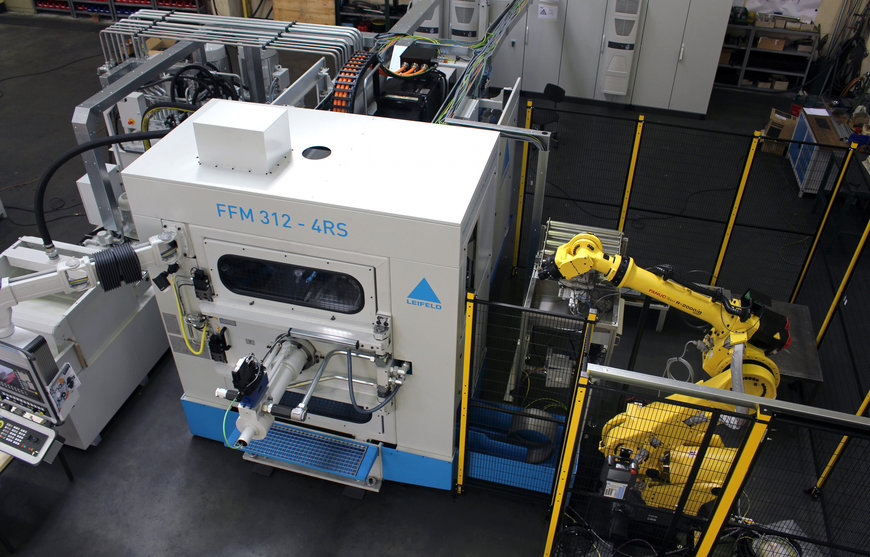

The company offers two different machine production series and flow-forming processes - the FFM series for backward flow-forming and the RSC + RC machines for biconical forward flow-forming. The difference here is the feed direction of the rollers and the flow direction of the material. Both form steel wheels without a tube in large or small quantities.

Manufacturers can produce cylindrical components such as the rim rings on the FFM machine. To get exact ring widths, measuring devices record tolerances in the circular ring, which are compensated by the machine control system - without additional trimming. “A modified cross-section of the output sheet metal ring saves weight,” explains Nillies.

How does that look in practice? He points to the equipment. A conveyor belt transports the preform, which was cutted from stripe, rounded and welded into a sheet metal ring, to the measuring device. If everything fits, a robot picks up the component and places it in the machine's loading device. There, the preform is automatically pushed onto a mandrel and fixed. The main spindle drive sets the mandrel with preform in a turning motion. Under CNC control, the roller, which runs in the opposite direction, flow-form the material in an axial direction. The wall thickness of the preform is reduced to the desired thickness. The final component length is permanently monitored and stopped in the machining program when the final rim ring width is reached. A scraper on the machine side then removes the finished part from the tool mandrel onto the unloading chute. Finally, a robot takes the flow-formed component out of the machine. The automatic quick-clamping device for tool mandrels and rollers minimises set-up times and thus increases cost-effectiveness.

“With cylindrical counter-rotating flow-forming, we can use universally applicable tools for different wheel widths,” explains Nillies. “The preform is easy to measure; there is a high degree of work hardening and no need to cut off excess material. That is what makes this machine so popular at our customers.”

Forward flow-forming for car wheel rims

With biconical forward flow-forming, the preforms for rim rings can be produced not only at an optimised weight, but also at an optimal weight. However, this is only possible for biconical components with a cylindrical inner diameter and axial clamping range - such as the drop-center area. Leifeld offers the RSC + RC series for this purpose. A loading device or a robot picks up the preformed component and places it in the machine. There, it is picked up by two mandrels in a form-fit and force-locked manner. Two co-rotating rollers each press the material in the direction of the axial feed in opposite directions. The area not yet involved in the forming process is pushed in front of the roller. “The machine thus ensures a symmetrical distribution of forces and a very high degree of rotational accuracy for the component,” says Nillies.

With forward flow-forming, no additional calibration expansion and no section length measurement is required. Greater preform and sheet metal tolerances can also be used. The excess material is then removed in another machine so that the desired material thickness and length are achieved exactly. The component is therefore free of weight differences resulting from the sheet metal thickness tolerance of the pre-material.

“Manufacturers can use our machines to design the wheels as they are required by vehicle producers - light with a high payload,” promises Nillies. “They can thus safely withstand increasing competitive pressure in the future as well.”

Source: Leifeld Metal Spinning GmbH