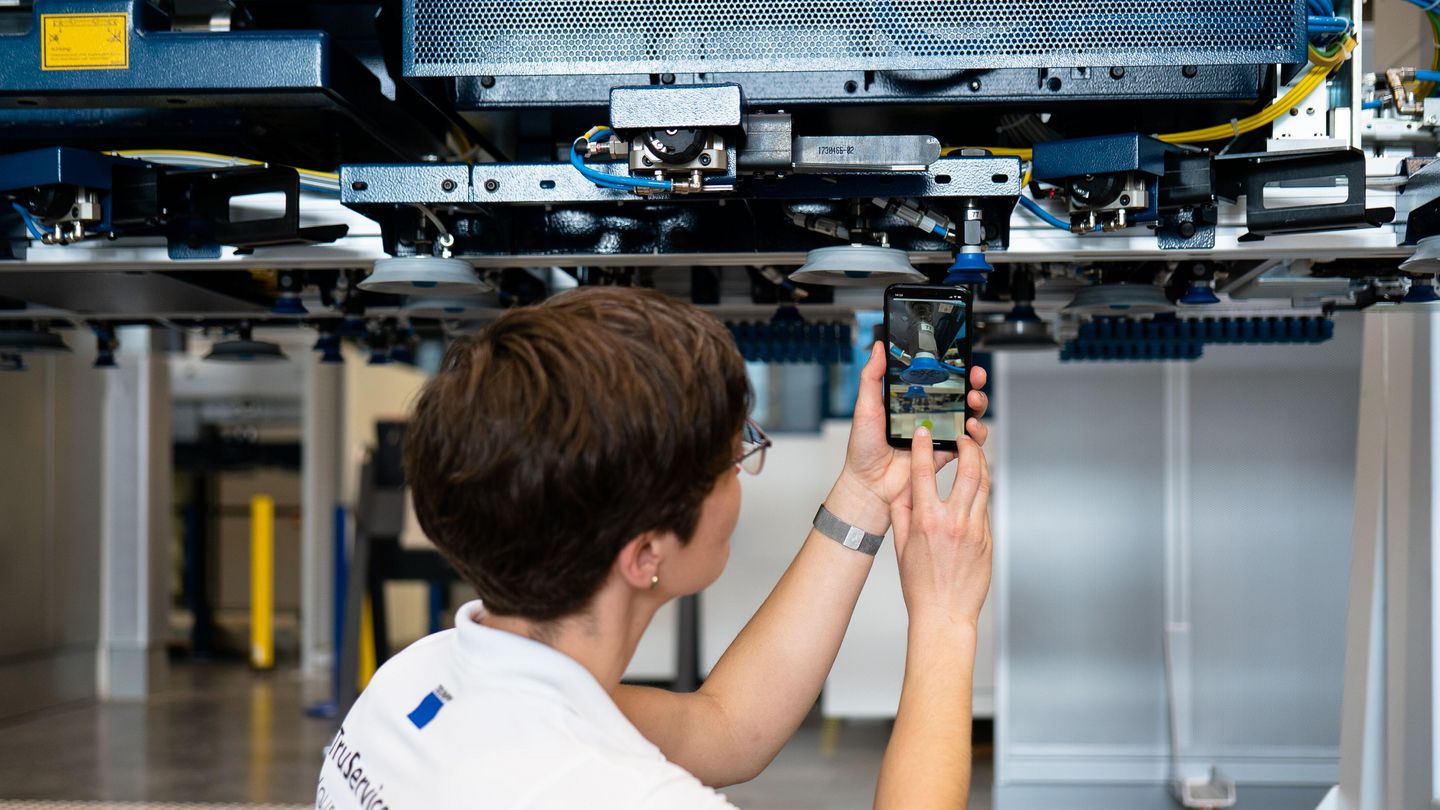

TRUMPF recently presented a new Easy Order app feature at its INTECH virtual trade show: an artificial intelligence (AI) solution that makes it much easier and faster for customers to order spare parts. Machine operators can now identify and order over 10,000 different service parts and wear parts in a matter of seconds. All they have to do is pull out their cellphone and take a picture of the part they need.

"Wear and tear on the shop floor eventually makes it impossible to read material numbers on spare parts. And some wear parts are difficult to mark in the first place. That can make it tough for customers to identify and re-order the right part," says Arun Anandasivam, who is responsible for the MyTRUMPF customer platform. With the new AI feature, the Easy Order app recognizes the part instantly, allowing the machine operator to submit the order without delay. TRUMPF is now also planning to make the AI solution available in its Service app.

Simpler ordering increases flexibility

Parts such as suction cups and filters come in many different, but similar, variants. In the past, many of these differences could only be spotted by very experienced users – but AI object recognition can identify the correct variant instantly. This solution is particularly helpful for spare parts and consumables that sheet-metal fabricators rarely need to order. “All you need is a smartphone, so production managers, programmers and operators can order the parts they need while they’re standing at the machine without requiring any in-depth knowledge. Sometimes the app can even identify the part while the machine is still running! That makes ordering easier and boosts flexibility on the shop floor,” says Anandasivam.

The part recognition process works on the basis of an artificial neural network. TRUMPF continuously populates this network with photos of the various items in order to train the system. The AI solution uses this selection of images to develop algorithms for object recognition. The database steadily increases in size as more photos from real production environments are added.