By: Chi-Chuan Cheng

The Multi-Layer Co-Extrusion Film Blowing Machine plays a vital role in modern plastic production with its benefits of high efficiency, automation, precision, and energy efficiency. It finds applications not only in food, building materials, and agriculture but also in fields like medicine, chemical, and electronics.

To cater to the rising demand for multi-layer film products and meet consumers' desire for an improved quality of life, many companies invest in researching, developing, and producing new functional materials utilizing multi-layer film technology. With the market leaning towards automation and diversification, the Multi-Layer Co-Extrusion Film Blowing Machine remains crucial equipment for enhancing production efficiency and expanding market share.

Multilayer Films in High Demand: A Look at Market Trends

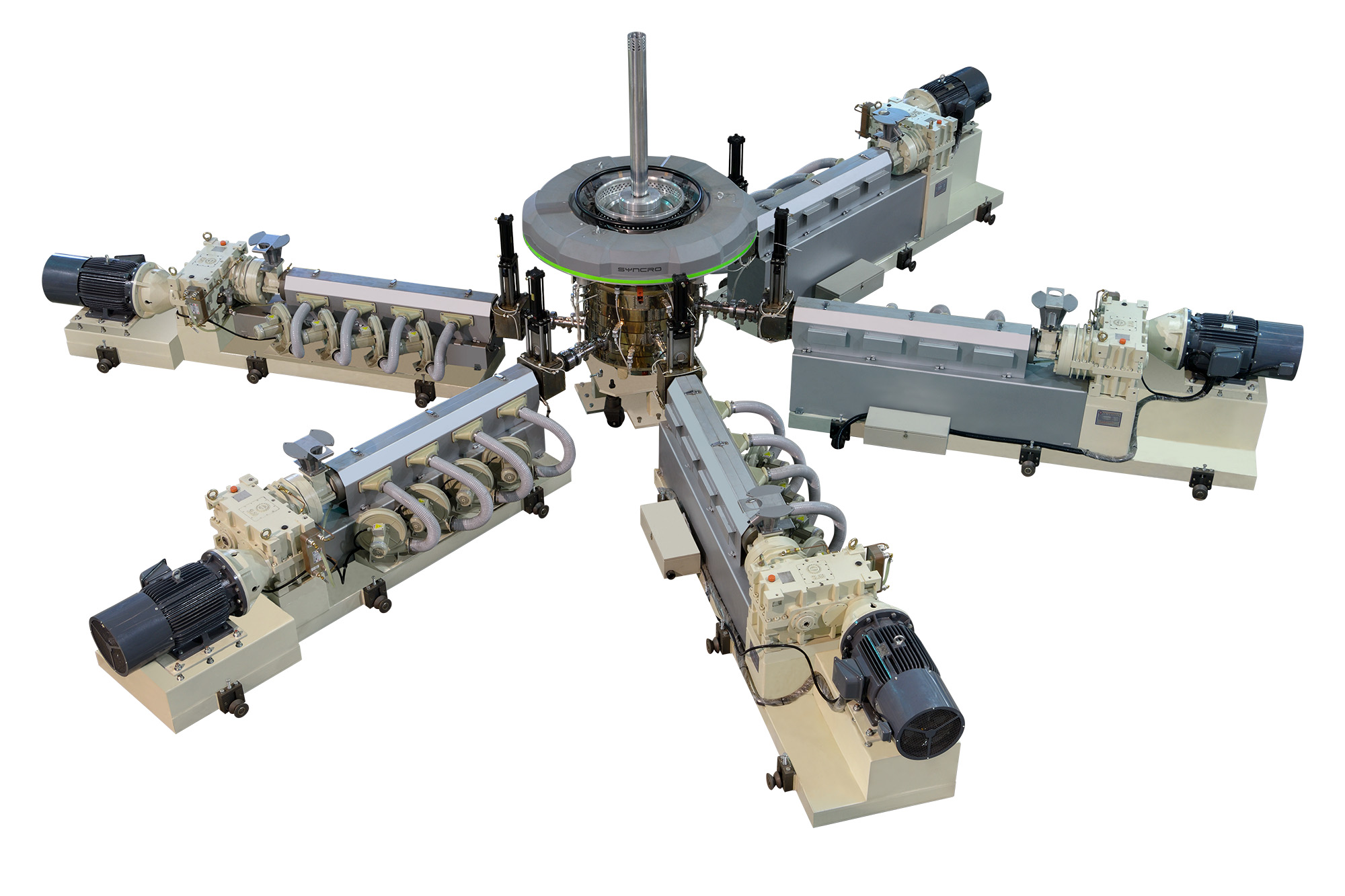

"Multilayer Films Market: Maximizing Growth Share and Opportunities by 2027," as marked by MarketWatch experts, predicts rapid growth in the consumption market for multilayer films from 2023 to 2027. Multi-layer film products with 5 to 7 layers or even more are becoming increasingly popular, and blown film machines with over 5 layers are becoming the mainstream due to the widespread use of raw materials. Chyi Yang Industrial Co., Ltd.'s advanced 5-Layer Co-Extrusion Blown Film Machine is a frequently chosen example and well-liked model for producing films used in the food packaging industry.

Chyi Yang's 5-Layer Co-Extrusion Blown Film Machine produces a type of packaging film known as "vacuum skin packaging." This film is made from high-barrier oxygen-resistant materials and has excellent toughness and stretchability. It can be used to package goods in a 3D effect and has properties such as a good barrier effect, high transparency, and an easy-tear design for convenient opening. The film adheres closely to different goods or various surfaces (material substrates) and can be easily peeled off. These advantages effectively reduce the outflow of blood and water from food, minimize the need for preservatives, and eliminate freezer burn, prolonging the shelf life and freshness of food. PX Mart, a Taiwan fresh food market leader, designated this film for use in their stores in 2022, sparking a conversation about its benefits.

Furthermore, the vacuum skin packaging produced by Chyi Yang's 5-Layer Co-Extrusion Blown Film Machine can also be applied to non-meat products, such as tools. The device also keeps up with the trend of the circular economy and can be used with recycled material to produce this film. "Effective use of high-performance blown film equipment with multi-layer film formulations is the key to gaining a competitive advantage in the market," concludes an expert.

Multi-layer products, comprising of multiple materials with enhanced physical and mechanical strength, offer better abrasion and tear resistance for product packaging and protection. Multi-layer products with five or more layers have high barrier properties, making them ideal for applications such as protecting cell phones, tiles, and computer screens. However, for multi-layer products with adhesive on the outermost layer, such as body films and screen protectors, smoothness and thickness control are crucial. To meet consumers' quality expectations, modern film manufacturers must use advanced high-speed blown film equipment with composite functional materials to adjust parameters, monitor precise formula calculation, and detect thickness actively while automatically recovering waste.

Mastering Trends and Upgrades: Staying Ahead in the Industry

Manufacturers of multi-layer co-extrusion high-speed film blowing machines will continue to innovate and improve existing technologies like using barrier materials, PA nylon and EVOH, as well as suitable TIE adhesives, while also developing new functionalities for each layer. In the future, machines with five or more layers will become the new favorite in the market, emphasizing product diversification. These machines will continue to improve and upgrade to showcase their unique advantages and value across various industries.

To meet new challenges and increase their competitiveness, businesses must innovate their technology to meet consumer demands. They should focus on energy conservation, cost reduction, ESG sustainability concepts, upgrade equipment, optimize production techniques, and develop innovative formulas to produce diversified products. By understanding market demands and consumer expectations, companies can expand their market share and maintain their leading position.