Tianjin Hengrui Plastic Machinery Co., Ltd. (Tianjin Hengrui) is positioned to produce high-end plastic sheet products in China, and has maintained this record for more than 20 years. With years of accumulation of expertise in technology and production process, Tianjin Hengrui has been monitoring current market demand in order to provide high-quality sheet extrusion equipment for the industry.

Mr. Wei Liguo, General Manager of Tianjin Hengrui, explains: "Tianjin Hengrui always puts product quality first, and is well positioned in the middle and high-end markets with commitment to become a leading domestic middle and high-end sheet extrusion equipment supplier. We can provide customised solutions and excellent services for machine users."

The company's main plastic sheet and plate extrusion line; PC optical sheet extrusion line; PET single/multi-layer sheet extrusion line; PP/PS high-barrier sheet extrusion line, etc., with fine workmanship and high quality, not only firmly occupy the domestic mid- to high-end market but around 20-30% of the products are already being exported overseas. When talking about the market situation in the past two years, General Manager Wei said, "Our products are mostly customised and need to be debugged on site. Affected by the epidemic, the current overseas orders are basically at a standstill but the company's overall steady sales is sustained.”

Mr. Wei Liguo, General Manager, Tianjin Hengrui Plastic Machinery Co., Ltd.

Tianjin Hengrui has positioned itself in the high-end market even from the beginning of its plant’s operation. In order to ensure strict product quality control, Tianjin Hengrui provides complete production lines - from extruder to winding or cutting, stacking, side material recovery, electrical installation. Thus, it is no surprise that its products are comparable to similar equipment offered by companies in Europe, America and Japan. Tianjin Hengrui’s advantage is that the price of its equipment is only half of those with similar specifications sold by suppliers in Europe and America. No wonder Tianjin Hengrui's customers come from Sweden, Germany and other high-end manufacturing countries. Mr. Wei said that the company developed a very high product accuracy standards such as 1mm sheet thickness error of +-0.01mm, and this is written into the contract for transparency.

Tianjin Hengrui's related machine parts, accessories, electrical control parts and so on have been used and tested for many years. Its good reputation of being in the business for many years proves that Tianjin Hengrui's products are more stable, more reliable, and guarantee longer life. The company has a professional technical team and efficient mechanical maintenance and after-sales service team to provide customers with full solutions to serve their needs.

High-barrier sheet production lines at their best

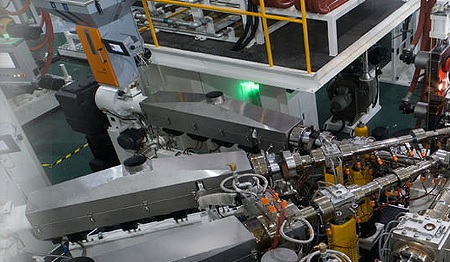

General Manager Wei believes that blister packaging has irreplaceable advantages. The high-barrier sheet production line is one of the company's core competitive products, which has an absolute advantage in the domestic packaging market. For example, the company has developed and now offers high barrier sheet material production line capable of turning out finished product with width of 800mm, thickness of 1-3.5±10-25μm and with maximum yield of 1300kg/h. With 6 extruders co-extrusion, it has been possible to achieve a maximum of 9 layers co-extrusion production. The exhaust extruder ensures that the exhaust port of the screw does not run out of material and the extrusion pressure is stable under the condition of full vacuum. Imported melt pump and online edge material crushing device are selected for crushing and collecting two cut edge materials. The machine is controlled by PLC and connected to Germany ILLIG thermal forming machine. This kind of sheet material is mainly used for food, medicine, cosmetics and other packaging, not only can it effectively block oxygen but it also can block the smell emitted by the packaging so as to achieve the purpose of long-term quality and freshness preservation of the packaged product.

9-layer co-extrusion barrier sheet line from Tianjin Hengrui

"From the original 3 layers, 5 layers of co-extrusion, now high barrier sheet development to 7 layers and 9 layers are possible with our machine, and with a capacity rising from 300 kgs/hour up to 1.5 tonnes at present. For more than 20 years, Tianjin Hengrui has always focused on the customers’ requirements, making production more efficient and maintaining the leading technology in the industry. The advantages of having advanced technology and reliable machine performance have enabled us to win the market, and accumulate a number of loyal and quality customers,” Mr. Wei said.

On the future developments in the extrusion industry, Mr. Wei is optimistic as he explains: "Plastic sheet extrusion moulding machine will play an increasingly important role in the application field, market demand will still increase and that is a good prospect. The equipment from Tianjin Hengrui can match European and American counterparts in terms of the level of technology while offering a price advantage. No matter how the market changes, our goal is always to provide users with excellent equipment and perfect service. In the future, we will continue to provide customers with equipment that guarantee low power consumption, high production rate, minimal failure, precision, low noise, long life; and at the same time products that comply with environmental protection and safety requirements.”

For more information, visit: http://hengruitj.com/en/