Today, plant operators are subject to increasing competitive pressure, which means that efficiency must be increased in all areas of the company. This applies to manufacturing, processing and finishing in flat strip production as well as to processing and distribution in and via metal service centres.

Particularly with regard to thickness measurement systems such as those of the EMG iTiM product family, the question very often arises during modernisation to what extent the reuse of modules and the use of existing design solutions is possible. Due to the strong penetration of the production chains with thickness measurement systems of all kinds, the partial reuse of components and integration solutions results in significant cost advantages for modernisations. Existing measuring systems and plants can be adapted to modern standards through extensions or conversions.

Economic efficiency takes the key role in this decision. Often the existing electrotechnical equipment, such as the automation and drive technology, no longer meets the required safety standard and the state of the art. In addition, the availability of isotope sources over longer periods of time is not assured and new purchases of the radioactive sources used in thickness measurement are no longer possible. The same applies to the procurement of spare parts for thickness measurement systems, which are no longer offered by the original manufacturers. However, it may also be that the operator know-how for the old systems is only limited or no longer available.

Roughly classified, the following options and their combination are on the EMG delivery programme for modernisations:

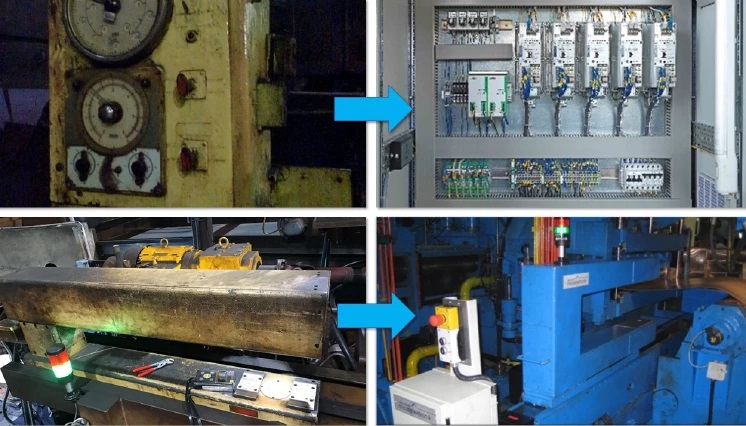

1. Replacement of the control cabinet, the analysis software and necessary adaptations of interfaces.

2. Replacement of the radiation sources and/or detectors - e.g., renewal of the X-ray generator and the X-ray detection unit - or, in the case of isotope sources, their continued use.

3. New C-frames or replacement of other construction elements such as brackets and guides.

Turn old into new with EMG iTiM

The savings when retrofitting an existing installation can be more than 70 % compared to a new purchase (incl. all associated planning, purchasing and project costs). This is partly due to the modularity of the EMG iTiM system components, especially with regard to the sensor and detector technology, and the high flexibility in the design.

Conclusion:

Due to the many years of experience of our "Thickness Measurement Team" with regard to all process steps of flat strip production, we can develop a modernisation concept tailored to your application at any time. Since EMG supports the user and customer in all questions of modernisation from start to finish - from conceptual design, construction and delivery to installation and assembly - if desired also as a key-turn project, the customer takes neither economic nor technical risks.