During their one-year honeymoon, cycling from France to Cambodia, founders Francois and Charlotte were mesmerized by nature showing itself at its best and at the same time being confronted with how mass consumerism and the production of cheap plastic has led to enormous plastic waste pollution we all know today. This led to the creation of The Plaf, also known as The Plastic Flamingo, a social enterprise based in the Philippines that collects and transforms plastic waste into a range of sustainable construction materials which can be used to build new schools, housing, and shelters to help make this country more resilient against the many natural hazards it faces yearly.

International Plastics News for Asia had the chance to talk to Francois Lesage, Founder and CEO of The Plaf, on how the enterprise is helping alleviate the impact of plastic waste by upcycling into useful products.

Please provide a brief overview on how Plastic Flamingo started in Southeast Asia. Which countries in the region do you currently operate?

Mr. Lesage: The Plaf began as a collection network in 2018 when, during a trip in Southeast Asia, my wife Charlotte and I were inspired by the beauty of nature and decided to do something concrete to protect the environment, particularly in the aspect of marine conservation. Thus, the Plastic Flamingo (The Plaf) was born to collect and recycle plastic waste, to prevent it from entering the oceans. Currently, we only operate in the Philippines.

What are the products that Plastic Flamingo offers and how do these products contribute to reducing plastic waste?

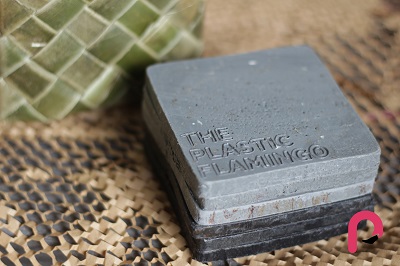

Mr. Lesage: Our products contribute to reducing plastic waste since they are made completely of plastic waste. We have the eco-boards/eco-lumber which are very durable making them an ideal construction material. The lumber can be exposed without losing their properties making them suitable for outdoor projects.

The Plaf transforms plastic waste into sustainable construction materials.

The planks we produce from recycled plastic content are turned into furniture and one of our bestsellers is the Plaf cube which has been optimised as an ideal office bin to collect more waste. It is very robust making it suitable for both indoor and outdoor use. The Plaf cube is entirely made from our planks, so you can showcase how the plastic that is being collected is turned into these planks. The bin is quite heavy, making it theft proof!

We also have a range of outdoor and indoor furniture. The high bar set is made from our posts, so they are quite sturdy and robust. The set is good for two people and come in two colours, light or anthracite gray. We also have a classic outdoor furniture that can withstand extreme temperature. The 100% recycled outdoor bench is perfect for parks, resorts, playgrounds, and other recreational facilities. Our 6-seater outdoor dining set is an ideal addition to the garden and is durable that it can spare you from worries of degradation under natural conditions. We also produce indoor dining set. These are some of our products made from recycled plastic and we are also developing and designing furniture according to our customers’ specifications.

In utilising recycled plastic for upcycling, do you have any specific requirements, like what technology or methods do you apply?

Mr. Lesage: We accept all types of plastic, as long as they are clean and dry. To recycle this plastic, we shred it into smaller pieces. Then, the plastic undergoes a process called extrusion, which allows them to be formed into the shape of the eco-lumbers we produce. For eco-boards, the shredded plastics are compressed with a high-pressure compression machine. We can also turn the plastic into pellets that can be used as a replacement for virgin plastic. This is done through our pelletizing machine.

Can you explain briefly how The Plaf organises and cooperates with recycling partners?

Mr. Lesage: We collect our plastic waste through collection points set up by our collection partners in different areas around Metro Manila. Once these collection points are full, our partners deliver the plastic waste to our warehouse or contact us to pick up the plastic waste from them. Once the plastic arrives at the warehouse, they are sorted according to type. Afterwards, they are shredded and extruded to create our products. Our sorting and production are done in the same area, in our warehouse.

What makes The Plaf different from other entities that are engaged in recycling and upcycling?

Mr. Lesage: The products we create are made of 100% plastic. We do not include aggregates in our products. Our products are also proven to be of high quality and have similar workability to wood.

Outdoor and indoor furniture are produced from 100% recycled plastics.

What are the challenges that the company had to overcome in its operations given the present economic and pandemic situation?

Mr. Lesage: Our plastic waste collection actually accelerated during the pandemic, where we saw mounting plastic waste. Our biggest hurdle, though, was adjusting to pandemic restrictions that prevented face-to-face work, which really affected the efficiency of our warehouse operations and tested our communication and teamwork.

But then we have a highly competent team, our Plaf team. Even during the COVID-19 pandemic, we have grown into a proud team of roughly 30 members, all with different stories. Some of us have international backgrounds, with lots of experience in the field of consultancy, operations, project management and architecture. Most of us, however, did not have the same privilege to obtain a degree and were born in poverty. The Plaf aims to provide opportunities to individuals from low income families so they can develop a new set of skills which will hopefully help them grow out of poverty. The furniture pieces we offer are all been made by our factory employees, from collecting the waste, sorting, shredding and transforming them into lumber and boards to making them into these awesome range of furniture.

Are your products for domestic market only or do you export them? What has been the response of your markets to these products?

Mr. Lesage: Currently, our products are for the domestic market. Generally, the response to our products has been favourable, especially since they are a good solution to a known problem (plastic pollution). We've been able to design outdoor furniture sets, office furniture, boardwalks, and bike racks. Currently, we are seeking to strengthen our operations so we may be able to meet the demand for our products.

Do you have plans to expand your operations in Asia? If yes, where and what are the plans?

Mr. Lesage: This isn't our priority right now. Surely we would love to see The Plaf go international, but we would like to focus first on strengthening our hold on the market here before expanding to others.

The Plastic Flamingo

E-mail: hello@theplaf.com

Website: www.theplaf.com

- This article also appears in the International Plastics News for Asia - June issue. To read the e-zine, click here.