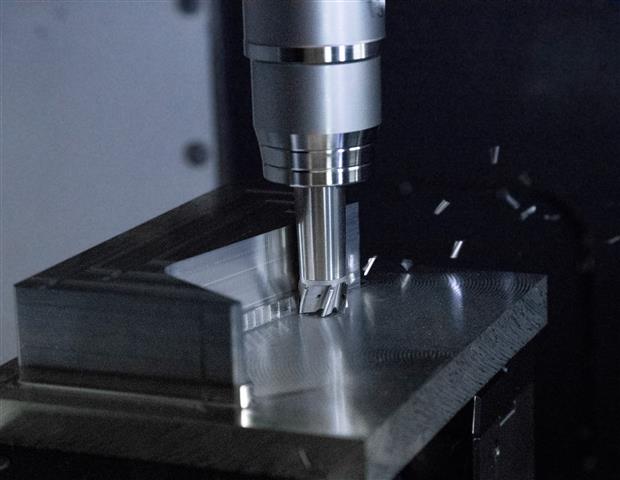

Pioneering tool features ensure a long tool life and reliable processes.

From aluminium and magnesium to fibre-reinforced plastics, PCD can handle them all! If you think that this is down to the hardness, you would be right: the synthetic diamond cutting material PCD (polycrystalline diamond) has inherited a hardness that is almost equivalent to its natural cousins. This means PCD milling tools from Ceratizit are able to hold their own against extremely abrasive materials – both in terms of tool life and attainable quality.

Hybrid tools: pioneers break new machining ground

Geometries that were difficult or even impossible to produce with conventional technologies are now a reality thanks to additive manufacturing strategies. For example, the number of cutting edges on a milling cutter can be ramped up to the maximum with 3D printing, which in turn drastically increases the chip removal rate. Once you add high cutting speeds into the mix, users stand to benefit from significantly reduced processing times. What's more, specially positioned coolant holes always supply the PCD cutting edges with the best possible cooling and remove chips quickly.

The screw-in cutters are available in diameters from 10 to 32 mm with a variable tool length using appropriate tool holders. With projection lengths of 2.5xDC, the PCD milling cutter is also offered in a hybrid design with a solid carbide base body. In order to maintain the high machining quality at all RPMs, the tools have a high helix angle that ensures quiet running.

Performance heroes in aluminium and graphite

Anyone who has to process graphite as well as aluminium will be impressed with the new PCD end mill. It uses up to four cutting edges to race through the materials at very high cutting speeds. On top of that, the end mills exhibit clear processing advantages when it comes to circular milling of holes or grooves. For example, far fewer radius corrections are required before the end of the tool life in comparison to solid carbide tools. This means the milling cutters last longer, as even the extreme abrasive conditions have little effect on them. The soldered PCD cutting edges also mean time-consuming adjustment work has become a thing of the past, which further minimises idle times and ensures constant machining quality.

CERATIZIT's PCD milling tools ensure a long tool life and reliable processes even with extremely abrasive materials.

CERATIZIT Deutschland GmbH

Marketing Communications

Daimlerstraße 70 87437 Kempten Germany

T. +49 831 57010-3405

F. +49 831 57010-3649

E. Norbert.Stattler@ceratizit.com