Guidelines

Kennametal offers general guidelines for drill sizes that will leave an appropriate amount of material for the reamer to efficiently size the finished hole: <1/4-inch = .010-inch, 1/4-inch to 1/2-inch = .015-inch, 1/2-inch to 1-1/2-inch = .025-inch. A common misconception is to leave too little material for the reamer to remove. The reamer needs enough material to make its cut. Too little material will cause the reamer to rub or burnish which results in accelerated wear and poor surface finish. Cutting speeds should be about two-thirds that of drilling SFM for similar material, and feeds should be two to three times higher.

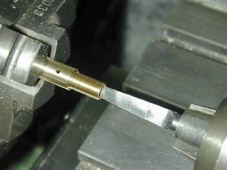

Chatter in reaming operations

Chatter is one of the most common causes of poor reamer life and hole finish. It is characterized as synchronized vibrations that are set up in the cutting tool, workpiece, and machine, or a combination of vibrations in all of these elements. This vibration causes the tool to deflect against the workpiece at a continuous, rapid, and often irregular pace. The tool誷 attempt to restore balance and resume its natural position against the vibration creates chatter. Consequently, chatter leaves poor or torn finishes and can lead to tool failure. Chatter can be caused by several reasons and can have devastating effects on the quality of the application. Some of the more common reasons include: excessive speed, lack of rigidity in the bushing or machine, insecure holding of the workpiece, excessive overhang of the reamer or spindle, too light of a feed, and insufficient rake or clearance. Reamers usually perform better at higher feed rates and lower speeds because of the small amount of metal they remove during an application. A general rule is to run the reaming tool at feed rates from 200 percent to 300 percent higher than those for drilling. Feed rates will vary depending on the material being reamed. Speed rates should be two-thirds of typical drill requirements. This will enable the tool to cut, rather than burnish or rub, the material. Increasing the feed rate will promote tool stability in the workpiece and reduce deflection between the tool and workpiece. If chatter persists, check the rigidity of the tool in the bushing or machine. Ensure that the holder is secure in the spindle. Often chatter is caused by some component of the machine set-up, and not by the tool. Be sure to check the holding mechanism for worn or loose bushings or holders. Replace any worn parts that cannot be adjusted and eliminate any movement through adjustments. It is also helpful to check the spindle and other driving parts for adequate strength. Weakened driving parts may cause deflection under the cut. Eliminate any unnecessary overhang of the reamer or holder. Remember that using the shortest possible tool significantly increases rigidity within any tool. Shorter shanks create less vibration and reduce the danger of deflection and chatter. It is important to select the correct style or design of the tool. Also consider the type of material being reamed. Choose a style that provides sufficient rake orAir Jordan IV 4 Shoes