In today’s practical and cost-conscious world, sheet-metal parts have already replaced many expensive cast, forged, and machined products.

The reason is obviously the relative economy of operation, easier implementation for mass-production, as well as greater control on the technical parameters. In most of the sheet metal operations

punching or pressing operation is the main or initial operation in the process sequence. Automating this operation results in reduced lead time and also can reduce human effort.

Automation can be defined as the “technology concerned with application of

mechanical, electronic and computer-based systems to operate and control

production”. There are many reasons for automating the process. The reason may be

to reduce manufacturing lead time, to increase labor productivity or to improve the

worker safety, etc.

Punching Process:

The press is the punching machine tool designed to punch blank of sheet by applying mechanical force or pressure. The presses are exclusively intended for mass production and they represent the fastest and more efficient way to form a metal into a finished punched product. In manual or conventional methods of pressing the disadvantages may be:

-

angular misalignment of the sheet

-

higher material handling time and manufacturing lead times

-

reduced safety for the worker

Programmable Logic Controllers

Fig. 1 PLC System block diagram

A Programmable controller is a solid state user programmable control system with functions to control logic, sequencing, timing, arithmetic data manipulation and counting capabilities. It can be viewed as an industrial computer that has a central processor unit, memory, input output interface and a programming device. The central processing unit provides the intelligence of the controller. It accepts data, status information from various sensing devices like limit switches, proximity switches, executes the user control program store in the memory and gives appropriate output commands to devices like solenoid valves, switches etc. In this project, sensors and PLC system is interfaced with the conventional punching process for achieving the automation.

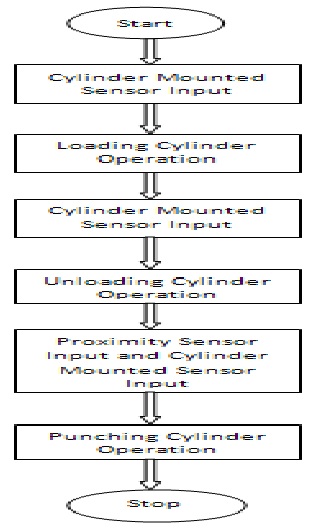

Working Methodology:

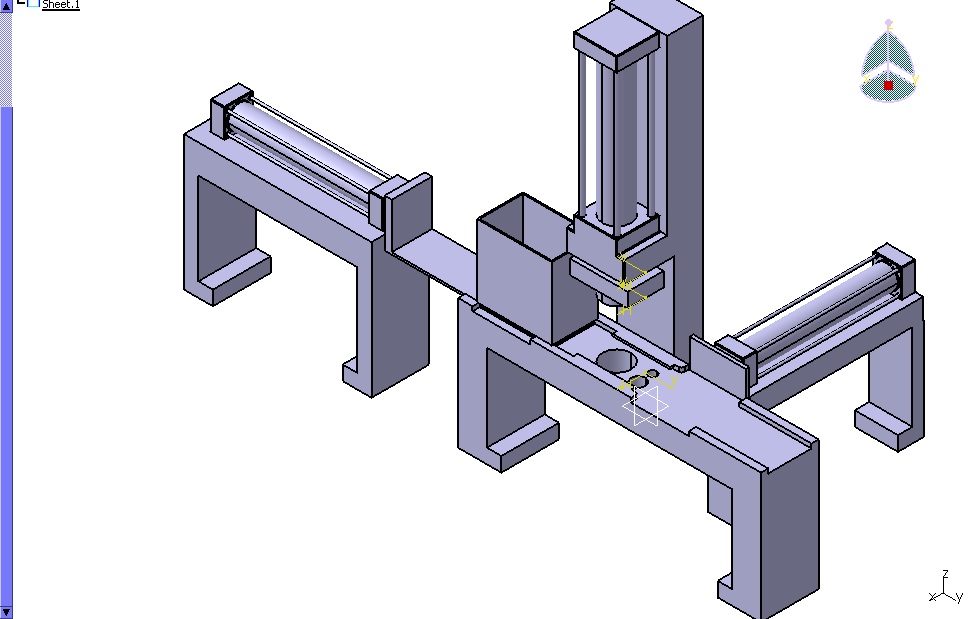

Design and modeling of the system:

Fig. 2 Model of the punching machine

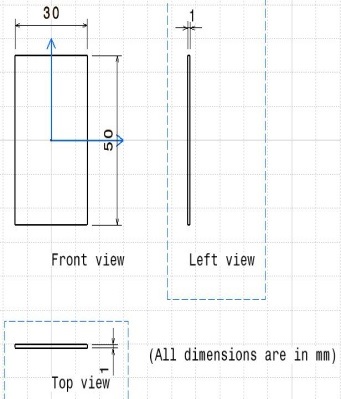

Actual Component:

Figure shows the actual dimensions

Ladder Logic Programming:

Ladder logic is a programming language that represents a program by a graphical

diagram based on the circuit diagrams of relay logic hardware. It was primarily used

to develop software for programmable logic controllers (PLCs) used in industrial

control applications. The name is based on the observation that programs in this

language resemble ladders, with two vertical rails and a series of horizontal rungs

between them.

Conclusion:

In this paper a method of controlling the operations of punching machines is

discussed. By using Programmable Logic Controllers as the controller of the system,

good control over the system can be achieved, manufacturing lead time of the system

can be reduced by developing automatic feeding mechanism and worker safety can be

increased by reducing the human participation in the process.

Reference

[1]. Aditya Polapragada, Sri Varsha, “Pneumatic Auto Feed Punching and

Riveting Machine”, International Journal of Engineering Research &

Technology (IJERT), Vol. 1 Issue 7, September – 2012, ISSN: 2278-0181.

[2]. Vijaylaxmi.G.Biradar, Siddharam Patil , R M Lathe, “Automation of Sheet

Bending Machine Using Electro Pneumatic Devices” International Journal of

Scientific & Engineering Research Volume 3, Issue 9, September-2012 1

ISSN 2229-5518.

[3]. Handbook of die design, Second Edition, 2006, McGraw-Hill Handbooks,

Ivana Suchy.

[4]. Materials Handbook, Fifteenth Edition, 2008, Mc-Graw-Hill Handbooks,

George.S.Brady, Henry.R.Clauser.

Air Jordan XX9 29 Shoes