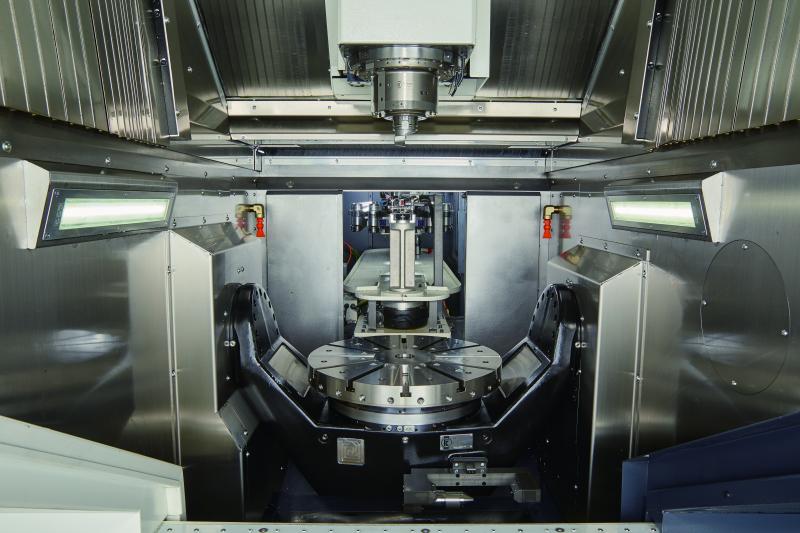

Buffalo Machinery further extended the structure of G6 and developed 3 different machine concepts to meet various industrial demands, which are G6 Standard, G6 Compact for floor space-saving, G6 APC for automation and G6 MT for mill-turn function.

With built-in spindle of 15,000 or 20,000 rpm, G6 Standard offers high-speed machining and 600mm diameter table with up to 600kg loading capacity. G6 APC offers options of 2-pallet, 6-pallet and 10-pallet with robot configuration to increase autonomy and flexibility. G6 APC has the back-loading system which allows the workpiece loading and unloading to be done while machining to reduce downtime and enlarge working time. Moreover, the machine can be integrated into a 12-pallet FMS system. The FMS controller gives full power to make the production as flexible as needed. The working area is totally accessible for job preparation, standalone operation and supervision. For those who are looking for the maximum integration of metal-cutting processes in a single step, reducing the complexity of the process and the chance of error in the clamping, G6 MT with the capacity of 500mm diameter table size and loading of 350kg for turning and 500kg for milling definitely is the best choice.

AXILE G6 series is ready to be integrated with the ARTTM System which is the industry 4.0 technology with reliability, predictability and automation functions. AXILE G6 series with ARTTM System can be integrated into a smart factory system to ensure the 24/7 automatic operation without unexpected downtime.

AXILE G6 machine and ARTTM system are going to be showcased at Hall 27 Booth B63 of EMO 2019. Please do not miss out this great opportunity to check the advanced machine and technology.

Buty Niemowl?ce