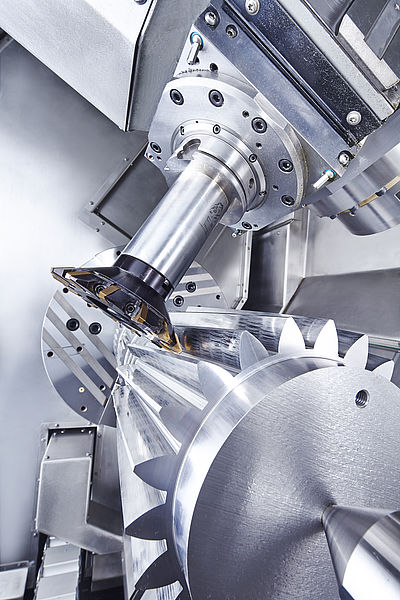

The trend towards the production of flexible gears on 5-axis machining centres has been continuing for many years. WFL has recognized the trend and has already been able to inspire its customers worldwide with numerous installations.

In cooperation with the Swiss company Euklid, the leading provider of advanced CAD/CAM solutions for 5-axis machining, WFL is now going one step further.

Euklid has been offering a CAD/CAM solution for flexible gear milling on universal machining centres for many years. In close cooperation with Euklid a tailor-made GearCAM solution has now been developed especially for MILLTURN customers. This enables the production of gears to be optimized and the lead time, measured against current industry standards and the highest quality requirements, to be reduced to a fraction. A digital twin of the MILLTURN allows a complete simulation of the process.

This enables easy troubleshooting and virtual optimization of the machining process. The new WFL GearCAM makes it possible to measure gears in the machine by means of a measuring cycle and ensure validation of the geometry before removing the component. WFL GearCAM is available specifically for spur and helical gears, herringbone gears and bevel gears.

The user-friendliness of the software is outstanding, as various strategies for machining individual teeth are freely selectable. WFL GearCAM optimizes, depending on the production requirements, the milling paths in such a way that tolerances are maintained with a minimum number of paths. The cutting and performance data can be taken from an integrated tool database. WFL GearCAM contains many functions for different types of gearings (even in small batches) and can be configured individually.

WFL GearCAM can be purchased by MILLTURN customers from September 2020.