The right bearing for every application

The fact that not every bearing is equally suitable for such complex and multilayered requirements as described in the introduction is understandable. We will not therefore satisfy this challenging area of application with just one design. This would show insufficient thought and would seriously contradict our principle of seeking the best solution in both technical and economic terms for the bearing arrangement. We therefore have the most comprehensive range of rotary table bearings. Based on this product range, proven on many occasions, our customers can select the appropriate bearing for their application. This gives security, a technical advantage and a high level of cost-effectiveness. In the machine tool, only the right bearing arrangement will ensure perfect machining results and the minimum of non-productive time. In bearing selection, we offer support through both our knowledge and our many years of experience in this field, see guide to bearing selection.A guide to bearing selection

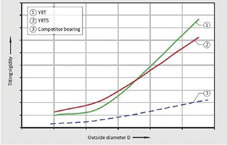

Rotary table bearings have, due to their geometry and design, quite specific characteristics. For the design of the bearing arrangement, this means: if it is to be operationally secure, low-maintenance or maintenance-free and economical, the correct bearing type of the correct size must be used. This will prevent over dimensioning and at the same time ensure that the bearings have a long operating life.

Step-by-step process

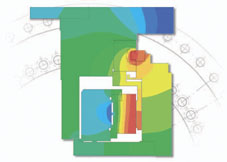

In the design of the bearing arrangement, it is necessary to take account of and weigh against each other a number of performance parameters that, in some cases, differ from each other and, in none too rare cases, conflict with each other. Nevertheless, standardization can often be achieved within certain limits, since many rotary axis bearing arrangements can be traced back to similar essential parameters. Based on our long experience in the design of such bearing arrangements, selection is generally found to be carried out in the following stages: ● Preparation of a design brief in which all influences on the bearing arrangement are recorded. The more precisely these values are known and the more comprehensively they are taken into consideration, the higher the operational security and cost-effectiveness with which the bearing position can be designed. The influences that come into question here are as follows: loads, speeds, operating temperatures, mounting space, environmental conditions, required rating life, friction, lubrication and maintenance, fitting and dismantling of the bearings, and annual quantity required. ● Preliminary bearing selection in accordance with the catalogue. Specific technical publications provide all the information that is required for preliminary selection of a bearing. ● Design of the bearing arrangement using BEARINX . With the aid of this modern calculation program, it is possible to achieve secure dimensioBlack Friday 19

● Design of the bearing arrangement using BEARINX . With the aid of this modern calculation program, it is possible to achieve secure dimensioBlack Friday 19