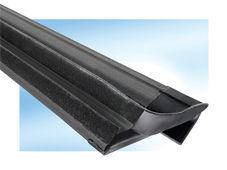

KraussMaffei Berstorff GmbH has developed an innovative line concept for the production of 2-component profiles made of PP and TPE-V. Two or three single-screw extruders of different size form the core elements of the co-extrusion line. The first line of this type used for the production of high-quality window profiles for the new VW Golf VI has already been successfully commissioned at the customer''s premises. The profiles are composed of a polypropylene profile clamping element, TPE-V sealing lips and a flock tape laminated onto the lips after the discharge from the extrusion die. The decisive benefits offered by two-component profiles are easy recycling, low part weight and reduced production cost. The co-extrusion line features a typical V-type extruder arrangement. The primary extruder ?in most cases designed as a TE 90 with a processing section length of 30 D ?is used for processing the PP material. The additional single-screw extruders TE 75 and 45, with processing section lengths of 28 to 30 D each, deliver the extruded TPE-V at an angle of 45 degrees to the PP material. KraussMaffei Berstorff GmbH Tel: +49-511 5702 237 Fax: +49-511 5702 613 Website: www.kraussmaffei.com Access code: RE5118Nike

KraussMaffei Berstorff GmbH has developed an innovative line concept for the production of 2-component profiles made of PP and TPE-V. Two or three single-screw extruders of different size form the core elements of the co-extrusion line. The first line of this type used for the production of high-quality window profiles for the new VW Golf VI has already been successfully commissioned at the customer''s premises. The profiles are composed of a polypropylene profile clamping element, TPE-V sealing lips and a flock tape laminated onto the lips after the discharge from the extrusion die. The decisive benefits offered by two-component profiles are easy recycling, low part weight and reduced production cost. The co-extrusion line features a typical V-type extruder arrangement. The primary extruder ?in most cases designed as a TE 90 with a processing section length of 30 D ?is used for processing the PP material. The additional single-screw extruders TE 75 and 45, with processing section lengths of 28 to 30 D each, deliver the extruded TPE-V at an angle of 45 degrees to the PP material. KraussMaffei Berstorff GmbH Tel: +49-511 5702 237 Fax: +49-511 5702 613 Website: www.kraussmaffei.com Access code: RE5118NikeComposite profiles for automotive applications

Source: Release Date:2009-07-14 298

Semiconductor/Electronic ChipSemiconductor / Electronic Chip

Add to Favorites

KraussMaffei Berstorff GmbH has developed an innovative line concept for the production of 2-component profiles made of PP and TPE-V. Two or three single-screw extruders of different size form the core elements of the co-extrusion line. The first line of this type used for the production of high-quality window profiles for the new VW Golf VI has already been successfully commissioned at the customer''s premises. The profiles are composed of a polypropylene profile clamping element, TPE-V sealing lips and a flock tape laminated onto the lips after the discharge from the extrusion die. The decisive benefits offered by two-component profiles are easy recycling, low part weight and reduced production cost. The co-extrusion line features a typical V-type extruder arrangement. The primary extruder ?in most cases designed as a TE 90 with a processing section length of 30 D ?is used for processing the PP material. The additional single-screw extruders TE 75 and 45, with processing section lengths of 28 to 30 D each, deliver the extruded TPE-V at an angle of 45 degrees to the PP material. KraussMaffei Berstorff GmbH Tel: +49-511 5702 237 Fax: +49-511 5702 613 Website: www.kraussmaffei.com Access code: RE5118Nike

KraussMaffei Berstorff GmbH has developed an innovative line concept for the production of 2-component profiles made of PP and TPE-V. Two or three single-screw extruders of different size form the core elements of the co-extrusion line. The first line of this type used for the production of high-quality window profiles for the new VW Golf VI has already been successfully commissioned at the customer''s premises. The profiles are composed of a polypropylene profile clamping element, TPE-V sealing lips and a flock tape laminated onto the lips after the discharge from the extrusion die. The decisive benefits offered by two-component profiles are easy recycling, low part weight and reduced production cost. The co-extrusion line features a typical V-type extruder arrangement. The primary extruder ?in most cases designed as a TE 90 with a processing section length of 30 D ?is used for processing the PP material. The additional single-screw extruders TE 75 and 45, with processing section lengths of 28 to 30 D each, deliver the extruded TPE-V at an angle of 45 degrees to the PP material. KraussMaffei Berstorff GmbH Tel: +49-511 5702 237 Fax: +49-511 5702 613 Website: www.kraussmaffei.com Access code: RE5118Nike Add to Favorites

You May Like